All Machinery Equipment

Home » All Machinery Equipment

Concrete Pumping Machine

Concrete pumping machines usually uses pressure to continuously transport concrete along the pipeline. Our popular products are mainly concrete boom pump truck, trailer pump, concrete mixer pump, etc.

Concrete Mixing Machine

Concrete mixing machine mainly refers to the equipment that mixes cement, sand aggregate and water and mixes it into concrete, or a combined device that concentrates on concrete mixing. It includes stationary concrete batching plant, concrete mixer, self-loading mixer, etc.

Crusher Machine

Daswell crushing machines are mainly used for crush large stones into small stones that meet construction standards. Our crushing equipment includes jaw crusher, cone crusher, sand making machine, impact crusher and so on.

Grinding Mill

The grinding mill is mainly used to grind raw materials into calcium carbonate powder. The grinding mill we produce mainly include ball mill and classification production line, roller mill, Raymond mill and so on.

Crane Machinery

Cranes include overhead crane, gantry crane, double-beam crane, single-beam crane and other special cranes, which are widely used in machinery, metallurgy, railway, steam, aviation, aerospace, nuclear power, oil, chemical, paper, mining, logistics and other fields.

Road Machine

Road machines are a series of equipment mainly used to build roads. It includes a stationary asphalt mixing plant, mobile drum mix plant, mobile forced asphalt plant, etc.

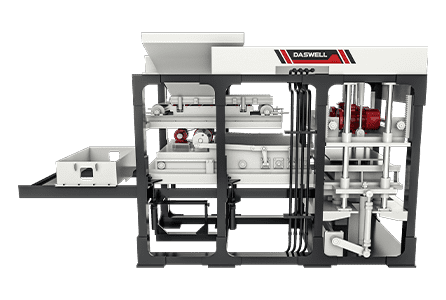

Brick Making Machine

Brick making machine is the device for producing various bricks. There is automatic brick making machine, hydraulic brick making machine, hollow brick making machine, mobile brick making machine and other brick machines we produce.

Engineering Machinery

In general, all the comprehensive mechanized equipment required for earthwork construction, road construction and maintenance, lifting and unloading operations and various projects are collectively referred to as engineering machinery. Our engineering machinery includes crawler excavator, wheel excavator, wheel loader, backhoe loader, truck mounted crane, rotary drilling rig, water well drilling rig and so on.

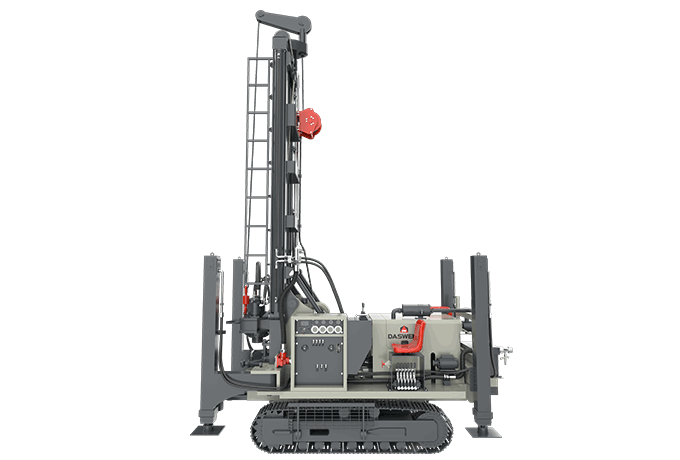

Drilling Rig

Daswell offers a range of high-performance drilling rigs suitable for geological exploration, water well drilling, and construction foundation projects.

Special Vehicle

Our special vehicles cover various fields, and our main products include LNG transport truck, road sweeping truck, vacuum sweeper, water tank truck, garbage compactor truck, tanker truck, high altitude operation truck, etc.

Powder Coating Machine

The powder coating machine is used for powder surface modification and film formation. We mainly produce three roller coating machine, vortex mill coating machine and high-speed mixing coating machine.

Laser Cutting Machine

Laser cutting machine includes single table high speed fiber laser cutting machine, fiber laser cutting machine for tubes, fiber laser cutting machine with enclosure and shuttle tables, etc. It is widely used in sheet metal processing, kitchenware and automobile, cars, lamps, saw blades, metal crafts, aerospace, medical devices, instrumentation and other industries.

Foldable integrated house

Folding boxes are a new type of housing developed in recent years, mainly solving the problems ofconvenient transportation and storage. Lt is suitable for transportation in remote areas such as xinj.ang and tibet. It has many features: space saving, easy loading and unloading, cost saving, greenand environmentally friendly, and long life.