Home » Road Machine » Asphalt Drum Mix Plant

Asphalt Drum Mix Plant

The asphalt drum mix plant is a kind of heating and mixing equipment for block asphalt mixtures, which is mainly used for the construction of rural roads, low-grade highways and so on. Its drying drum has functions of drying and mixing. And its output is 40-100tph, fitting for small and medium-sized road construction project. It has the features of integrated structure, less land occupation, convenient transportation and mobilization.

Brief introduction

Asphalt drum mix plant is also generally known as continuous mixing asphalt plant because it can produce asphalt mixture continuously instead of in batches like forced mix asphalt plant. Asphalt drum mix plant can be divided into stationary type and mobile type. According to our years of sales experience, if a customer chooses a drum mix asphalt plant, he will choose the mobile type in most cases.

Asphalt drum mix plant is generally used in the construction of township roads. Because it is very flexible, you can move it to the next construction site very quickly when one project is finished.

Components and features

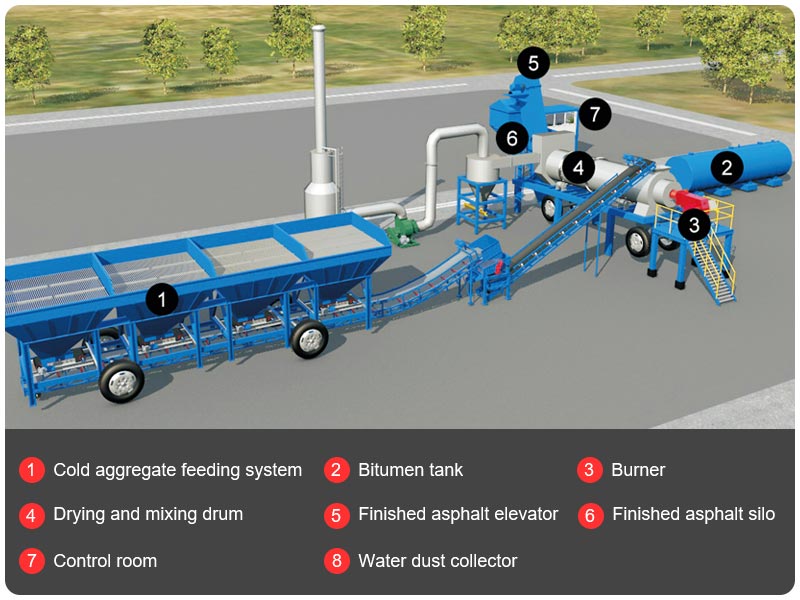

An asphalt drum mix plant consists of the cold aggregate feeding system, bitumen supply system, burner, drying drum, finished asphalt elevator, finished asphalt silo, water dust collector and control system. In the case of mobile asphalt drum mix plants, the components include an additional travel system.

Cold aggregate feeding system: Cold material generally refers to different sizes of aggregates. Customers can choose 3 or 4 cold material storage hoppers.

Bitumen supply system: The continuous asphalt plant uses a direct heat asphalt tank to heat the bitumen.

Burner: We have diesel burners, coal burners and gas burners to choose from.

Drying drum: It has the function of drying and mixing. Dry the aggregate entering the drum, at the same time, the drum rotates to complete the mixing of aggregate and asphalt.

Finished asphalt elevator: Lift the finished asphalt through the elevator to the finished asphalt silo.

Finished asphalt silo: Store the finished asphalt mixtures and unload it into a dump truck. Then the dump truck transports the finished asphalt to the construction site.

Water dust collector: Collecting dust generated during the production process.

Control system: It contains control room, operation desk, control cabinet, air conditioner, etc. It can realize semi-automatic control of the whole asphalt plant.

Working principle of asphalt drum mix plant

The asphalt drum mix plant process is relatively simple, which can be broadly divided into four major parts: batching, heating, mixing and storage.

Batching: The raw material of asphalt drum mix plant is mainly aggregate and bitumen. Aggregates are weighed in the batching machine, while bitumen is mainly controlled by adjusting the flow rate of the asphalt pump to control the percentage of bitumen.

Heating&Mixing: The weighed aggregate and bitumen are fed into the drying drum at the same time. After being dried and heated, the aggregate is mixed with the bitumen to complete the mixing process.

Storage: The finished asphalt mixtures will be fed into the asphalt storage hopper by the bucket elevator and then transported to the construction site by the dump truck.

What is the difference between a batch plant and drum mix plant?

The common asphalt plants on the market are generally divided into two types, drum mix type and batch mix type. So, what is the difference between these two kinds of asphalt plants? How should customers choose the right type and model? You can consider from the following aspects.

1.Raw materials

The raw material of drum mix plant generally includes aggregate and bitumen, no powder. The percentage of aggregate is about 94% and the percentage of bitumen is about 6%.

The raw material of batch mix asphalt plant includes not only aggregate and bitumen, but also powder. The proportion of aggregate is 90%, the proportion of mineral powder is about 4%, and the proportion of bitumen is about 6%.

2.Weighing system

The drum mix plant does not have the weighing system for aggregate and bitumen. Aggregate is weighed by adjusting the belt speed through a frequency converter, while bitumen is weighed by adjusting the flow rate of the asphalt pump.

Batch mix asphalt plants have the weighing systems for aggregate, bitumen and powder. This not only ensures the accuracy of the proportioning, but also the quality of the finished product.

3.Mixing system

The drying drum of drum mix plant has two functions: drying and mixing. Therefore, the aggregate and bitumen are mixed directly in the drying drum.

The drying drum of the batch mix plant is only used to dry and heat the aggregate. It is equipped with a double horizontal shaft mixer to mix the materials.

4.The quality of finished asphalt mixtures

Because of the above reasons, the quality of asphalt produced by drum asphalt mixing plants is not as good as the quality of asphalt produced by asphalt batch mix plants.

5.Applications

Drum mix asphalt plants are generally used for township roads or roads that do not require high grades. In addition, if the township roads are damaged and need to be repaired, drum mix asphalt plant is also ideal. And the forced mix asphalt plant is mainly used in the construction of highway, airport road, grade highway, etc.

6.Dust collecting system

The drum mix asphalt plant is generally equipped with water dust collector, while the forced mix asphalt plant is generally equipped with two-stage dust collector , cyclone dust removal + baghouse dust collector.

7.Price

Compared with the forced mix asphalt plant, the drum mix plant price will be slightly cheaper.

Things to consider before buying a drum mix asphalt plant

In order to buy the right drum mix asphalt plant, you need to consider a few aspects before you buy.

Consider where to buy the bitumen. Generally speaking, the bitumen needs to be purchased, and the form of purchase varies from place to place. In Africa, for example, the bitumen is in barrels or bags. This requires heating off the drum containing the bitumen, turning the bitumen into a liquid, and then pumping it into the bitumen tank. Whereas in Southeast Asia, you usually call the bitumen supplier and they will deliver it in an bitumen truck and pump it into the bitumen tank on site. So, you can first inquire about how bitumen is purchased in your area.

Consider the type of fuel for the burner, whether it is diesel, coal or natural gas. If you use diesel fuel, you generally need to consume 6 kg of diesel fuel per ton of finished asphalt. For coal it is 10 kg of coal (good quality coal) consumed per ton of finished asphalt. Because natural gas is more expensive, so few customers choose natural gas as fuel.

Depending on the amount of asphalt required for your project, choose a drum mix asphalt plant with the right output. Our drum asphalt plants range in capacity from 20t/h to 100t/h.

Check the local environmental protection requirements and choose the right dust collector. If the environmental requirements are high, you can choose the baghouse dust collector with good dust removal effect. If the environmental requirements are not high, you can choose the cheaper water dust collector.

Finally, you also need to consider the price of the drum mix asphalt plant and the service provided by the manufacturer. If there is a problem in the process of using the machine, whether the asphalt drum mix plant manufacturer can solve it for you in time.

Successful cases of asphalt drum mix plant

Due to its small footprint, easy to move, high productivity and cheap price, the drum mix asphalt plant has been sold to more than thirty countries, such as Philippines, Peru, Kenya, Myanmar, Guatemala, Pakistan, etc.

After receiving the message from the customer, our sales staff and engineers will quickly get in touch with the customer. Then they will further communicate with customers about the configuration and details of the product. In a word, many customers have already bought the satisfied drum mix plant from our company. After a period of use, they also all highly affirm and praise our company’s products and services.

The following is a real case of a customer from the Philippines. This customer is from northern Samar, Philippines. He bought MADP40 drum mix asphalt plant with 40t/h from us, mainly for building national ang highway.

A very important reason for this customer to choose us is because we have an office and warehouse in the Philippines, and he thought we could provide him with timely services such as installation, commissioning and maintenance. Here are some pictures of the shipment.

If you are planning to find a reliable drum mix asphalt plant manufacturer, our Daswell Machinery is a good choice!

Technical Data:

| Model | Capacity(t/h) | Weighing Accuracy(%) | Total Power(kw) | Fuel Consumption(kg/t) | ||

| Aggregate | Asphalt | Coal | Oil | |||

| MADP-40 | 40 | ±1.5% | ±1% | 75 | 10~13 | 5.5~7 |

| MADP-60 | 60 | ±1.5% | ±1% | 128 | 10~13 | 5.5~7 |

| MADP-80 | 80 | ±1.5% | ±1% | 165 | 10~13 | 5.5~7 |

| MADP-100 | 100 | ±1.5% | ±1% | 200 | 10~13 | 5.5~7 |