Home » Road Machine » Mobile Asphalt Mixing Plant

Mobile Asphalt Mixing Plant

Mobile asphalt mixing plant is a kind of equipment that mixes stone, asphalt and mineral powder according to a certain proportion to produce asphalt mixture. Compared with the fixed asphalt station, the unique walking system makes the transition more convenient.

Asphalt mixing plant refers to a complete set of equipment for mass production of asphalt. It can produce asphalt mixture, modified asphalt mixture, colored asphalt mixture. And it is a necessary equipment for the construction of expressways, grade roads, municipal roads, airports and ports.

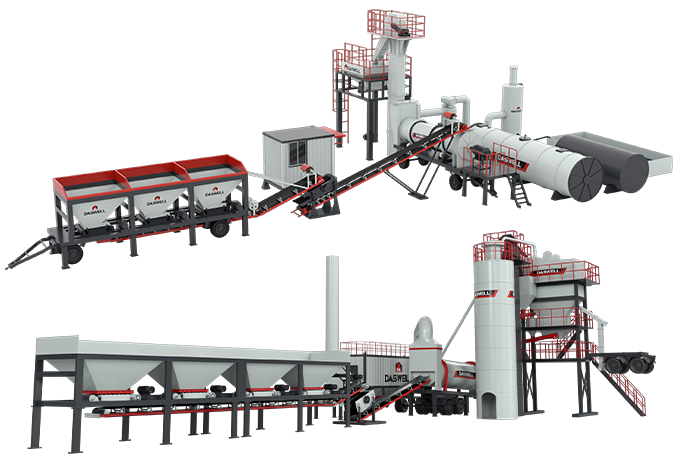

Types of mobile asphalt mixing plant

According to the way of migration, asphalt plants can be divided into stationary asphalt plant and mobile asphalt plant. Among them, mobile asphalt plants includes two types, namely the drum type and the forced type.

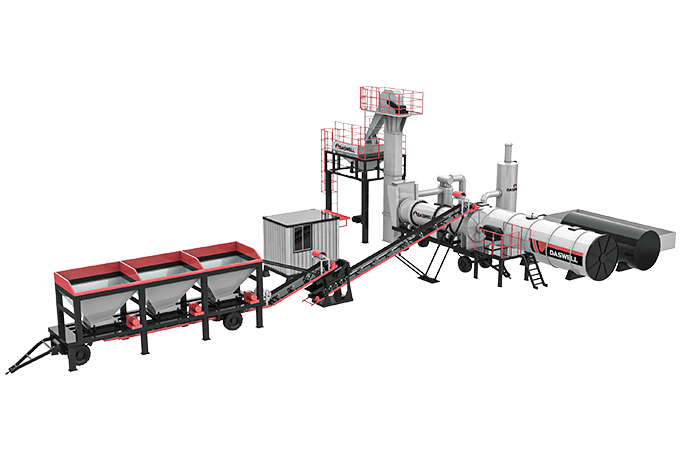

Mobile asphalt drum mix plant

The mobile asphalt drum mix plant is mainly composed of cold material supply system, asphalt supply system, drying and mixing drum, dust removal system, walking system and control system. Usually used for small and medium-sized roads or low-grade road construction projects. It has the advantages of small footprint, easy to move and low price.

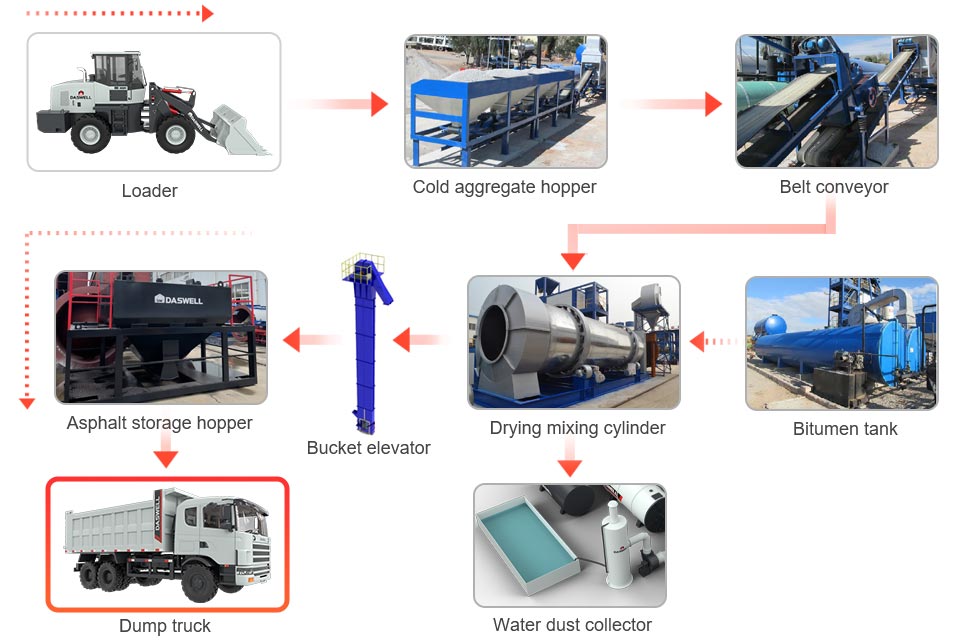

The main workflow is as follows:

- Use the loader to load the cold aggregates of different specifications into the cold aggregate hopper respectively. After that, they are conveyed to the vibrating screen through the belt conveyor, leaving the material smaller than 40mm to continue to the next step.

- Qualified cold aggregate is sent to the drying and mixing drum by the belt conveyor. At the same time, the asphalt is also sent to the drying mixing drum through the pipeline. After that, the cold aggregate and bitumen are mixed and dried in the drum to form a homogeneous finished bitumen. During this process, the dust contained in the cold aggregate will be sucked into the dust collector without causing pollution to the environment.

- Finally, the finished asphalt is lifted to the asphalt storage bucket by the bucket elevator for temporary storage and insulation. Wait for the dump truck to transport it to the construction site.

Mobile asphalt forced mix plant

The components and workflow of a mobile asphalt forced mix plant are basically the same as those of a fixed asphalt plant. The difference lies in the addition of a walking system, which makes the movement more convenient.

Because it adopts a forced mixer, the cold aggregate and asphalt can be fully mixed, so the quality of the finished product is relatively good. It is usually used to build expressways and airport roads with strict quality requirements. The mobile forced asphalt plant has the characteristics of high degree of automation, high finished product specifications, and convenient transportation.

The main workflow is as follows:

- First, use the loader to load the cold aggregates of different specifications into the collecting hopper respectively. After the primary weighing, the qualified materials are transported by the belt conveyor to the drying drum for heating and drying.

- During the drying process, the dust and moisture contained in the cold aggregate are sucked into the bag dust collector.

- The hot aggregate heated by the drying drum passes through the hoist to the vibrating screening system above the mixing building. They are screened into different specifications by the vibrating screen, and then respectively enter the storage hopper below. Afterwards, according to different ratios, they are put into the weighing device in turn and re-weighed.

- The mineral powder is transported to the temporary storage hopper through the powder elevator, and then to the weighing device for weighing. At the same time, the bitumen is sent to the bitumen metering device through the pipeline for weighing.

- Later, put the weighed aggregate, mineral powder and asphalt into the twin-shaft mixer in turn for mixing. When the specified time is reached, open the discharge door of the mixer. And put the evenly stirred mixture into the finished product warehouse. Finally, the mixture is put into the dump truck and transported to the construction site.

Mobile asphalt plant company

So far, our mobile asphalt mixing plants have been exported to various countries in the world. And many customers have given positive feedback to our asphalt plants.

On the one hand, our mobile asphalt mixing plant has a unique appearance, high performance, high efficiency, and can better match the construction needs. On the other hand, it is because we provide our customers with thoughtful service and reasonable prices.

Moreover, our asphalt plant is of various types, not only mobile asphalt plant but also fixed asphalt plant. If you need, you can contact us for more details and quotation.

How to choose a site for a mobile asphalt plant?

With the rapid development of infrastructure, the market application of asphalt mixing plants is also gradually increasing. Because the layout of the portable asphalt mixing plant has a very direct relationship with the long-term operation in the later period, the location selection is very important.

Distance from construction site

Only the right haul distance can maximize the profit of the mobile asphalt mixing plant and the quality of the asphalt mixture. Considering the paving temperature and transportation economy of the asphalt mixture, the distance between the asphalt plant and the construction point should not be too large. It is generally recommended that the transportation distance be within 80 kilometers, and the maximum should not exceed 100 kilometers.

Ease of supply of raw materials

Mobile asphalt plant requires a large amount of sand, slag and asphalt during production, and the combustion system requires oil or natural gas as fuel. The site selection should fully consider the timeliness of the supply of these raw materials and the cost of transportation.

Geological condition

Specifically, whether the site is threatened by geological disasters such as fractures and landslides; whether there is a large amount of stagnant water at the bottom; whether it is sandy land. All these factors have an important impact on the foundation construction of the asphalt mixing plant. And then directly affect the construction cost of the asphalt plant.

Surrounding environment

Asphalt mixing plant is a kind of equipment with a high degree of mechanization, so pollution such as dust and noise will inevitably be generated during the processing. Therefore, when choosing a construction location, schools and residential groups should be avoided as much as possible to reduce the impact on the surrounding environment.

Technical Data:

Mobile asphalt drum mix plant

| Model | Capacity(t/h) | Weighing Accuracy(%) | Total Power(kw) | Fuel Consumption(kg/t) | ||

| Aggregate | Asphalt | Coal | Oil | |||

| MADP-40 | 40 | ±1.5% | ±1% | 75 | 10~13 | 5.5~7 |

| MADP-60 | 60 | ±1.5% | ±1% | 128 | 10~13 | 5.5~7 |

| MADP-80 | 80 | ±1.5% | ±1% | 165 | 10~13 | 5.5~7 |

| MADP-100 | 100 | ±1.5% | ±1% | 200 | 10~13 | 5.5~7 |