What are the Different Types of Asphalt Mixing Plant?

Asphalt mixing plants use sand and gravel aggregates, bitumen, water, mineral powder, etc. as raw materials to produce different types of asphalt mixtures, such as modified asphalt mixtures, colored asphalt mixtures, etc. It is mainly suitable for the construction of highways, graded roads, airports, ports, etc. It has the advantages of wide application range, high efficiency, large output, stable operation, and good quality of finished asphalt.

There are many different types of asphalt mixing plants. Different types are suitable for different projects. So what types of asphalt mixing plant are available for you to choose?

Types of asphalt mixing plant

According to different classification standards, asphalt mixing plants can be divided into different types. For example, according to mobility, it can be divided into stationary and mobile types; according to different mixing methods, it can be divided into continuous drum mixing types and intermittent forced mixing types; and according to different production capacities, it can be divided into small, medium, and large asphalt plants.

In fact, there are three common types of asphalt mixing plants: forced mix asphalt plants, drum mix plants, and mobile asphalt plants.

Forced mix asphalt plant

As the name implies, the forced mixing asphalt plant is a kind of equipment that uses a forced mixer to mix asphalt mixture. It is also called asphalt batch mix plant. It is mainly suitable for projects with high requirements on project quality and output, such as municipal roads, graded roads, airport roads, etc.

Its advantages

- Modular design, reasonable layout, quicker and more convenient disassembly-transportation-installation.

- The core components adopt internationally renowned brands, such as Siemens motors, EBICO burners, etc., which reduces the equipment failure rate and prolongs the service life of the equipment.

- Mass production and large output range can meet the needs of projects of different scales.

- It is equipped with a two-stage dust collector. The dust removal effect is good, and it is suitable for areas with higher environmental protection requirements.

Drum mix asphalt plant

Drum mix asphalt plants use drying drums to complete the mixing of asphalt mixture. It is mainly suitable for projects with limited budget and low quality requirements for finished products, such as township roads and country roads. In addition, it is also suitable for road repair work.

Its advantages

- Compact structure and small footprint. It works well even in tight spaces.

- Easy to transport and transition. If necessary, it is equipped with a movable chassis and can be towed away directly by a trailer.

- Its internal structure of the drying drum is optimized, the heating speed is fast, and the stirring effect is good.

- The price is relatively cheap and the investment cost is low. It is cost-effective.

- The production process is simple and continuous production can be realized. The operation is simple and convenient.

Mobile asphalt mixing plant

The mobile asphalt mixing plant is named relative to the stationary asphalt plant. Because of its convenient movement and flexible transition, it has been welcomed by more and more customers in recent years. It is mainly suitable for projects with a short construction period and frequent transitions.

Its advantages

- The main components are equipped with trailers and chassis, which can realize quick relocation.

- Compared with the stationary aspjallt plant, there is no need to lay the foundation in advance before installation, and it is more convenient to use.

- The core components are made of wear-resistant materials for longer service life.

- The main equipment is concentrated on the mobile frame, which occupies a small area and saves space.

- Adopt PLC control system, automatic control, higher precision.

Difference between batch mix plant and drum mix plant

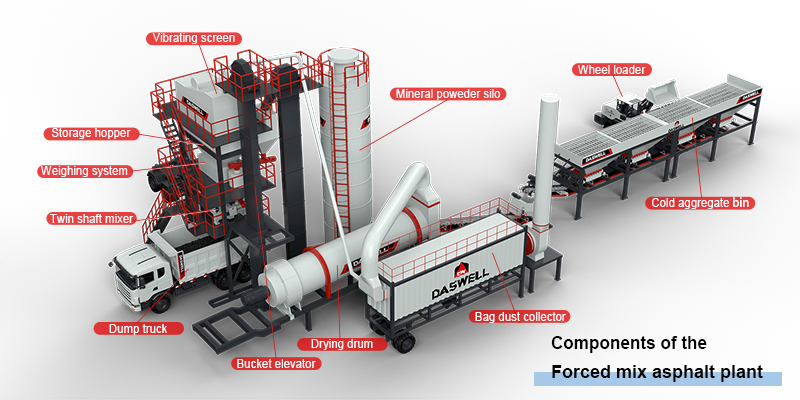

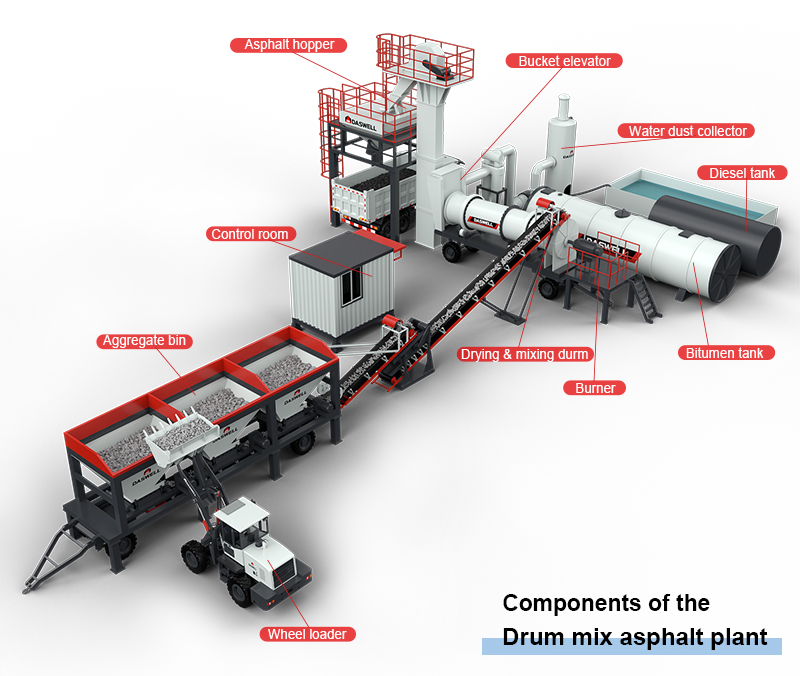

Different components

The components included in both kinds of asphalt mixing plants are: cold aggregate batching machine, drying drum, belt conveyor, asphalt tank, burner, finished asphalt storage bin, control room, dust collector, and finished product elevator.

In addition, the batch mix asphalt plant has more components than the drum mix asphalt plant: forced mixer, two different dust collectors, vibrating screen, electric control system, and hot aggregate elevator.

Because the components are different, their workflows are also different.

Different weighing systems

Batch mix asphalt plants need to weigh the material twice. The first weighing is done after the cold aggregate is fed into the aggregate batching machine. The second weighing is done before the hot aggregate is discharged into the mixer from the temporary storage bin. This is done to ensure the accuracy of the raw material ratios.

The weighing of the drum mix asphalt plant is relatively simple, only a rough weighing is required after the cold aggregate is sent into the batching machine.

Different mixing systems

The drying drum of the forced mix asphalt plant is used to dry and heat the materials. It is also equipped with a forced mixer for mixing materials.

The drying drum of the drum mix plant integrates the functions of drying, heating and mixing materials.

Different dust removal systems

Batch mix asphalt plants are generally equipped with two-stage dust removal. Commonly used dust collectors are gravity dust removal and bag dust removal, which have good dust removal effect and reduce pollution.

The drum mix asphalt plant is generally only equipped with a first-stage dust removal. The commonly used dust collector is water dust removal, which is cheap, but the dust removal effect is average.

Different quality of finished asphalt mixtures

Because of the accuracy of weighing and the configuration of high-performance mixers, compared with the drum mix plant, the finished asphalt quality of the batch mix asphalt plant is better.

Different capacities

The production range of the forced mix asphalt plant is 40t/h to 400t/h, while the production range of the drum mix asphalt plant is 20t/h to 100t/h.

Different prices

The price of forced mixing asphalt plant is slightly higher than that of drum mix asphalt plant.

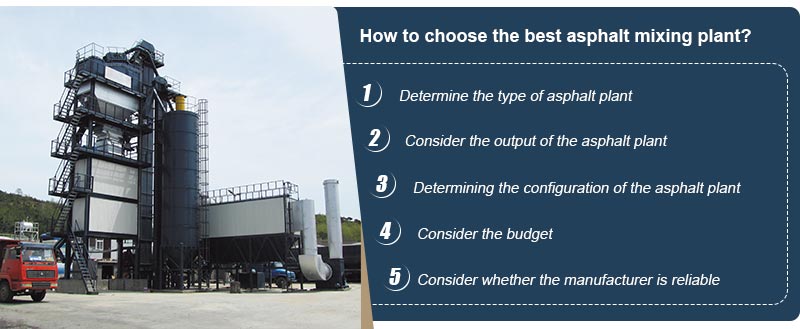

How to choose the right asphalt mixing plant?

Determine the type of asphalt plant

If your projects have a long construction period and high output requirements, or you want to build a high-quality grade road, you can choose a forced mix asphalt plant. If the road you want to build has a long distance and you need to move your equipment frequently, it is more convenient to choose a mobile asphalt plant.

In addition, if you are building a country road, or your investment cost is limited, you can consider choosing a drum mix asphalt plant. Alternatively, you can use the drum mix plant to repair roads.

Consider the output of the asphalt plant

According to the length of the construction period and the size of the total engineering volume, calculate the average asphalt mixture required per hour. If you need 40 tons of asphalt mixture per hour, then you can consider an asphalt plant with a capacity of 50 tons per hour or 60 tons per hour.

This is because the output of the asphalt mixing plant in the parameter table refers to the theoretical output. The theoretical output refers to the state that can only be achieved under ideal conditions. In actual operation, some problems may occur, so the theoretical output of the asphalt plant you choose should be slightly higher than the actual output you calculated. Only in this way can the needs of the project be met.

Ensure the configuration of asphalt plant

Different countries and regions have different requirements for road construction. Customers can determine the configuration of the asphalt mixing plant according to their actual situation.

For example, determine the type of dust collector according to local environmental protection requirements. If the local environmental protection requirements are high, you can choose the bag dust collector with better dust removal effect; otherwise, you can choose the cheaper water dust collector.

There are also three options for the raw materials of the burning system, namely coal, diesel and natural gas. Among them, the cost of using natural gas is relatively high. Of course, this also depends on the customer’s local resources.

The finished product silo are also available as the side-mounted silo and the lower-mounted silo.

Consider the budget

There are different types and models of asphalt mixing plants. Their prices are also different. Customers need to choose the most cost-effective equipment according to their budget.

The price of the drum mix plant is relatively cheap, and the lowest price is about tens of thousands of dollars. The minimum cost of a forced mix asphalt plant is about hundreds of thousands of dollars. The mobile asphalt plant has a slightly higher cost because it has a mobile chassis.

All in all, the price range for an asphalt plant ranges from tens of thousands of dollars to hundreds of thousands of dollars. This is also related to the different requirements of customers for equipment.

Consider whether the manufacturer is reliable

The first thing to look at is the time the manufacturer has been engaged in this industry of equipment production. If a manufacturer has been operating in the market for more than ten years, it proves that the manufacturer has some strength and has not been eliminated by the market competition.

You also need to check whether the manufacturer can provide reliable service. Regardless of pre-sales, on-sales or after-sales, you may encounter various problems. If a manufacturer can provide you with timely services, it can quickly solve your problems and save your time.

Then, you can also listen to previous customers’ comments on the manufacturer. This can best reflect whether the manufacturer is trustworthy.

Finally, if it is convenient, you can visit the manufacturer’s company and production factory.

Why choose DASWELL?

Daswell Group Co., Ltd is located in Zhengzhou City, Henan Province, China.

Since its establishment in 1986, Daswell Machinery has been focusing on the design, research and development, production and sales of construction machinery and mining machinery. Since exporting the first mixer to Colombia in 2009, Daswell has accumulated more than ten years of export experience.

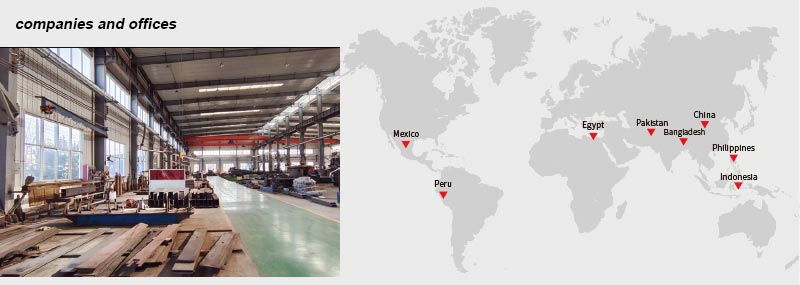

Up to now, we have exported our products to more than 80 countries around the world. We have also established subsidiaries and offices in 6 countries around the world, including the Philippines, Indonesia, Egypt, etc. Every export is a recognition from our customers to Daswell.

So, I believe you can choose the satisfactory asphalt mixing plant from our company!