Safety Operation Tips for Asphalt Mixing Plant

It is very important to understand the safe operating instructions of the asphalt mixing plant. The correct operation of the asphalt mixing plant can not only ensure the smooth completion of production, but also effectively protect the personal safety of the operators, and at the same time avoid damage to the asphalt plant to the greatest extent.

During the operation of the asphalt mixing plant, the operator needs to complete the whole operation skillfully and correctly. This requires the operators to be trained before they can start the job. So, if you want to operate the asphalt plant safely and effectively, what aspects need to be paid attention to?

Requirements for asphalt plant operators

- The operator of the asphalt mixing plant must go through professional training, pass the examination and obtain an induction certificate before they are allowed to operate.

- The operator must wear a work cap, work clothes, work shoes and other protective equipment when carrying out operations.

- During the operation of the asphalt plant, the operators need to continuously monitor the operation of each component, and are not allowed to leave their jobs without authorization. During operation, if the operators find that the equipment is abnormal, they should stop in time to deal with them.

- It is strictly forbidden for anyone to work or pass under the hopper when the hopper is raised. Therefore, before the operator starts the equipment, he should check the surrounding condition of the equipment to avoid accidents.

Before the asphalt mixing plant starts

- Check whether there is any material stored in the hopper of aggregate batching machine, hot aggregate lifting hopper, mixer and each storage hopper. If there is stock material, need to put the stock material clean, then make each discharge door in the closed state.

- Check whether all parts are in good condition, whether the transmission parts are loose, and whether the connecting bolts of each part are fastened and reliable.

- Check whether the lubricating oil and grease at each lubrication point are sufficient, whether the oil level of each reducer is up to standard, and whether the oil quantity of the pneumatic system is normal.

- Clean up the site, check whether the protective devices of each part are safe and reliable, and whether the fire prevention appliances are complete and effective.

- Check whether the quantity, quality, specification and model and other technical parameters of aggregate, mineral powder, bitumen, fuel and water meet the requirements of production.

- Check whether the temperature of the heat conduction system meets the production requirements.

- Check whether the voltage of the power supply meets the requirements of the rated voltage of the equipment, and the deviation is not allowed to be greater than 5%.

- Check whether the switch of the discharge door of each bin is flexible and whether the material level indication is normal.

- Check and start the air compressor to make it to the required air pressure for operation.

- Check whether the electrical components of each part such as switches, relays, motors and cables are normal.

- Check whether the display instrument panels are normal, whether the metering device is accurate and reliable, and if it is inaccurate, it needs to be adjusted accurately. Mainwhile, check whether the set gradation and oil-stone ratio meet the requirements of the project.

- Check the bitumen supply system and the temperature of the bitumen. After confirming that it is normal, turn on the asphalt pump to make it circulate by itself.

- Make sure that the water pump of the dust removal system of the equipment is in good condition, and ensure that the amount of water sprayed is stable and uninterrupted.

Asphalt mixing plant in operation

- After inspecting and confirming that the equipment is in normal condition, the inspector needs to sound the alarm in case there are people in the danger area and prompt the operator to go to work.

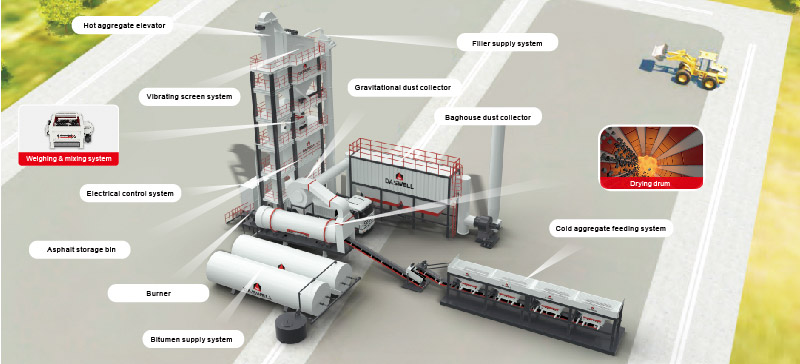

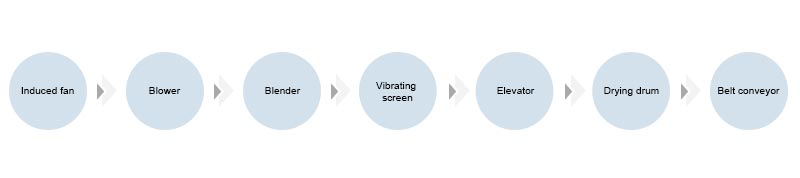

- After each component is ready, close the circuit breaker and air switch of each branch. Then turn on the induced draft fan, blower, mixer, vibrating screen, elevator, drying drum, belt conveyor, etc. in turn. During the start-up process, inspectors need to check whether there is any abnormality in the equipment, and give timely feedback to the operator.

- Start the above motor for 3 minutes, and after observing that there is no abnormality, you can ignite. Insert the oil gun, turn on the diesel pump and light the ignition to carry out the ignition. At the same time, turn on the pulverized coal machine and its adjustable-speed motor, adjust the damper of the induced draft fan and blower and observe whether the fire is lit. If it doesn’t light, try again until it does. After lighting the fire, turn off the diesel pump and pull out the oil gun.

- When the drying drum starts and stops, it must be operated according to the regulations. When the ignition fails, the operator should close the burner throttle in time and wait for sufficient ventilation before ignition. When the ignition needs to be adjusted, the high voltage power supply must be cut off first.

- At this point start feeding. At the beginning of feeding, the feeding amount should be controlled, otherwise the temperature will rise slowly. When the temperature rises above 100°C, the feeding amount can be gradually increased until normal. Observe the temperature change at any time, adjust the amount of aggregate and powder to ensure the temperature of the aggregate.

- First adjust the control system to the manual control mode, and produce 8 to 10 batches of asphalt mixture under the state of manual measurement. After ensuring the normal operation of the equipment, the control system is adjusted to the automatic control mode, and the asphalt mixture produced is sampled and inspected in time.

- Regularly check the status of each instrument panel. If abnormal conditions are found, adjust them in time.

- During the production process, the operator should always observe the outdoor situation and keep in close contact with the personnel in each position to ensure the normal operation of the equipment and the safety of personnel.

- Special attention is that the emergency stop button can only be used in emergency situations, and it is strictly forbidden to be used as a normal stop button. Once used, when starting up again, be sure to pay attention to the starting sequence of each component.

- When the motor is overloaded and triggers the protection device, it is generally necessary to find out the cause and continue to run the asphalt station after troubleshooting.

- It is strictly forbidden to pile tools and objects on equipment that is in operation.

After asphalt mixing plant shutdown

- Before stopping the machine, depending on the situation of hot aggregate storage bin, you can stop feeding when producing the last five to six batches of asphalt mixture. Then turn off the flame after another 2 to 3 minutes, stop the pulverized coal machine and the adjustable-speed motor.

- Pour the fine stone and sand into the mixing tank, stir for a while, and clean the residual asphalt mixture in the mixing tank. Finally, put away the remaining material in the hot aggregate storage bin.

- Turn off each motor in the opposite order of the start-up. It should be noted that when the machine is shut down, the drying drum and the feeding belt will continue to run until the temperature of the drying drum is lower than 90℃ before closing.

- Stop spraying bitumen immediately when the burner of the drum mix asphalt plant is turned off. When the drying drum is on fire, the burner, blower and exhaust fan should be turned off immediately, and the supply of bitumen should be stopped, and then fine aggregate with high water content should be put into the drying drum, and use dry powder or foam fire extinguisher at the external discharge port to extinguish the fire.

- After stopping the machine, the material on the belt conveyor and the residual depositing inside and outside the dust removal device should be removed and the asphalt pipeline should be cleaned.

- After shutting down, clean up the site, and carry out daily inspection and maintenance of the asphalt plant according to the instructions.

As a professional manufacturer of asphalt mixing plants, Daswell has professional engineers to guide the installation, operation and maintenance of the equipment. If you want to get more information about the operation skills and daily maintenance skills of asphalt mixing plants, please pay attention to the blog content regularly updated on our website.