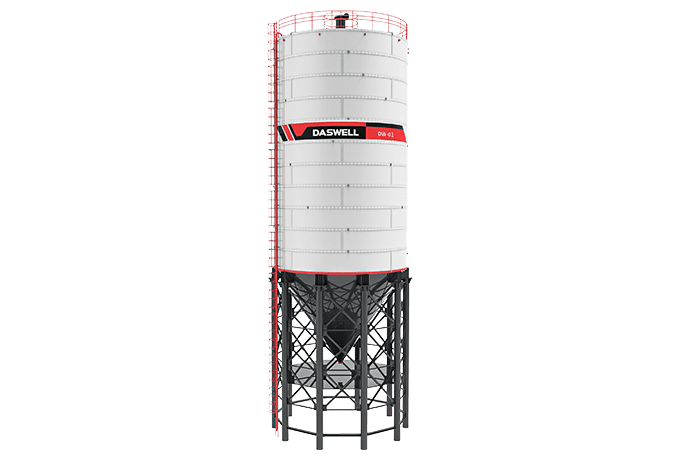

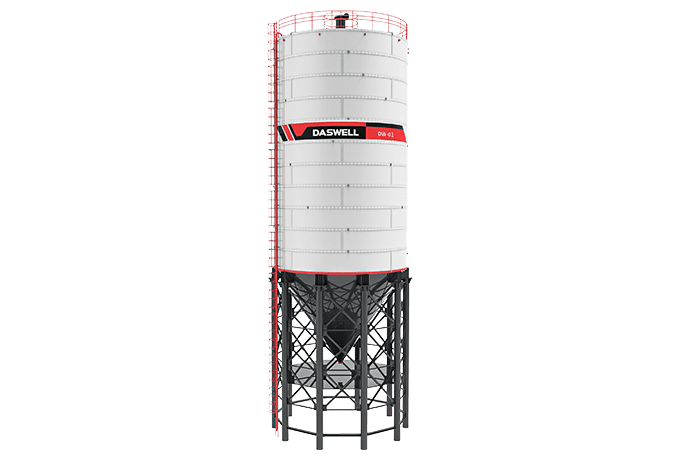

Bolted Silo

Bolted silo is a kind of bulk powder silo, which is a closed tank for storing bulk powder. It is suitable for storing bulk materials, such as cement, fly ash, lime, calcium carbonate, additives, chemical powder, etc.

What is the Bolted Cement Storage Silo?

The bulk cement storage silo provided by Daswell is a new type of silo body. It is a new type of silo that can be used after being transported to the construction site and assembled with bolts. This type of silo is completed by machining, which gets rid of the defects of roughness and limited conditions caused by traditional manual welding and gas cutting.

It has the advantages of short construction period, convenient installation, easy transportation, and can be transferred and reused. Daswell not only provides silos, but also committed to providing customers with turnkey solutions for the storage and transportation of various bulk powders.

Daswell bolted cement storage silos are often used for the concrete batching plants. Whether for the stationary concrete batching plant or the mobile type batch plant, the cement silo is useful. If you have interests on the full set of concrete batching plants, Daswell have various solutions for you.

Application of the Bolted Silo

Bolted cement silo is widely used in concrete batching plants, dry mortar plants, mining fields, water conservancy projects, tunnels, bridges, highways, terminal bulk material transfer and other export container transportation and transportation in areas where is inconvenient for large vehicles to enter and exit.

Why choose Bolted Silo rather than Traditioal welded cement silo?

When it comes to storing bulk materials like cement, fly ash, or powdered chemicals, bolted silos offer significant advantages over traditional welded silos. Daswell’s bolted cement silo stands out for its efficiency, cost-effectiveness, and versatility, making it the ideal choice for modern construction, mining, and industrial applications. Here’s why you should consider a bolted silo rather than the welded silos:

- Modular Design: The pre-fabricated panels are lightweight and compact. Thus, it is easy to transport the silos even to remote or confined job sites.

- No Heavy Welding Required: You just need to bolt the components together on-site simply. It highly reduces labor and installation time.

- Ideal for Temporary or Mobile Projects: Compared with the permanent welded silos, the bolted silo be disassembled and relocated for reuse.

- Reduced Material Use: Daswell bolted silos are made from high-quality but thinner steel plates, cutting down weight and freight costs.

- Minimal On-Site Work: You don’t need to employ a specialized welding team. It can be assembled quickly and requires only basic tools.

- Lower Maintenance: The precision manufacturing ensures durability, reducing long-term repair costs.

- Advanced Roll-Bending Technology: It ensures tight seams between panels, preventing air and water infiltration.

- No Leakage Risks: Unlike welded silos, bolted silos maintain consistent airtightness. If you choose the welded silos, it may develop cracks over time.

- Suitable for Sensitive Materials: It is perfect for storing cement, fly ash, and other moisture-sensitive powders.

- Adaptable to Various Sites: You can use it for concrete batching plants, dry mortar production, mining, hydropower projects, and more.

- Easy Expansion: It is applicable to add sections easily to increase storage capacity if you need.

- Ideal for Export and Remote Areas: The compact shipping dimensions make it perfect for regions with limited transport access.

Daswell’s bolted silo is a modern, cost-efficient, and reliable alternative to traditional welded silos. Whether you need temporary storage, easy relocation, or a durable long-term solution, the bolted design delivers faster setup, lower costs, and better performance. The silo cement storage has advanced technology and low maintenance cost. Especially, the maintenance cost per ton is generally 0.1 RMB/year, and the service life is longer.

For industries that value mobility, efficiency, and airtight protection, the bolted silo is the ideal choice. If you are interested in a customized bolted silo solution, contact Daswell for expert support!

How to install Daswell bolted cement silo?

what is the Daswell Bolted-type silo cost?

The price of a cement silo depends on its capacity, configuration, and customization needs. At Daswell, we offer high-quality, cost-effective silos starting from around $5,000 for compact models. As for the larger or specialized designed bolted silo, the price will be higher.

What Affects Cement Silo Pricing?

- Capacity – The small silos (e.g., 30-50 tons) are budget-friendly. If you want to buy 30-50 tons bolted silos, it will be economic. While the larger ones, which is about 100 tons will cost more.

- Design and Materials – The standard bolted silos are economical. If you want to customize, for example, the reinforced steel, insulation, it will increase costs.

- Additional Features – The dust filters, level indicators, pneumatic unloading systems, and insulation add value but also impact pricing.

- Logistics and Installation – Shipping to remote sites or complex assembly requirements may affect the total cost.

Why Choose Daswell Cement Silos?

Instead of overpaying for unnecessary features, Daswell helps you optimize costs without compromising performance. Whether you need a small silo for a mobile batching plant or a large-capacity storage system, we provide reliable, budget-friendly options.

Daswell Full Support for Bolted Silo Customers from Design to After-Sales!

At Daswell, we don’t just sell cement silos. We also provide end-to-end solutions to ensure smooth, cost-effective, and long-lasting bulk powder storage. Here’s how we stand out:

Free Customized Engineering Solutions

- Expert Design – Our engineers can analyze your working site conditions, capacity needs, and material type for designing the optimal layout.

- Tailored Configuration – Whether for a concrete batching plant, dry mortar factory, or mining project, we customize silos for improving your construction efficiency.

Simple Shipping and Installation

- Global Logistics Support – We will handle the shipping, so you don’t need to worry about transportation.

- Complete Accessories Included – When we delivering the products, each silo comes with a full set of spare parts for your easy maintenance.

Unmatched After-Sales Protection

- 1-Year Warranty – We offer you free repair services for any manufacturing defects.

- Lifetime Spare Parts Supply – The wearing parts, like filters, seals, and valves are available at original price forever.

- Technical Support – We can provide remote or on-site assistance if you need.

Cost-Effective and Durable Investment

- No Over-Engineering – We recommend the right silo for your budget, avoiding unnecessary upgrades.

- High-Quality Materials – Precision-made bolted panels ensure airtight, corrosion-resistant, and long-term storage.

Especially, we have many branches in different countries. For example, you can visit our office in Philippines, Indonesia, Mexico, Egypt and so on. Whether for the consolation or the maintenance, we can provide full set services for you.

Contact us now for a FREE consultation and quote! Let our experts optimize your bulk material handling system.

Woking Site of Daswell Bolted Silo for Stationary and Mobile Concrete Batching Plant

Daswell Customized Bolted Silo for your Specific Projects

Daswell provides cement silos with capacities ranging from 30 tons to 2,000 tons, catering to meet different project needs. With a proven track record, we have successfully exported 1,500 ton lime silos. It demonstrates our expertise in bulk storage solutions.

Our technical team can assess your specific requirements and recommend the most suitable silo for your project. For customized silo designs or model recommendations, feel free to contact us—we’re happy to assist!

Accessories and functions of cement silo for High Efficiency

To ensure optimal performance and efficiency for your projects, Daswell cement silos are equipped with high-quality accessories, including:

- Dust Collector – It is mainly used for minimizing powder spillage and preventing air pollution.

- Material Level Indicator – It provides real-time monitoring of material volume, enabling timely refilling or stopping to avoid overfilling.

- Safety Valve – It ensures pressure regulation and operational safety.

- Discharge Valve (Butterfly/Flapper Valve) – These valves can control material flow during discharge.

- Flow-Assist System (Air Cushion/Nozzle and Air Control Box) – This system prevents material compaction and clogging by breaking up deposits and ensuring smooth discharge.

These accessories enhance storage efficiency, safety, and environmental compliance, making Daswell silos a reliable choice for bulk cement handling.

For customized configurations or technical support, contact our experts today!

Tips for you to choose the right cement silo

Daswell has various bolted silos for you to choose. If you do not know how to choose the most suitable one for your own projects, here are some tips for you.

If you can not decide which is suitable for your projects, our engineers can guide you based on your project’s specifics. Just contact us for a free consultation!

FAQ About Daswell Bolted Silo

Technical Data:

| Capacity (t) | Diameter (mm) | Discharge Height (m) |

| 50 | 3260 | Customerized |

| 70 | 3260 | |

| 80 | 3260 | |

| 100 | 3260 | |

| 150 | 3600 | |

| 200 | 4500 | |

| 300 | 5050 | |

| 400 | 5500 | |

| 500 | 6600 | |

| 800 | 8000 | |

| 1000 | 8000 | |

| 1500 | 10000 | |

| 2000 | 12000 |