Raymond Mill

Raymond mill is used for getting coarse powder. It is usually used to grind calcite, limestone, talc, quartz, gypsum, feldspar, marble, mica, kaolin, rare earth, dolomite and other materials with hardness below 7 on Mohs scale and humidity below 6%.

What is a Raymond mill?

Raymond roller mill is a new type of mineral processing equipment with high efficiency and closed circulation, mainly used for grinding coarse powder. It has a relatively large feeding size, generally 20 to 30 mm. The discharge size is generally 45 to 180 microns.

In recent years, with the development of non-metallic minerals in the ultra-fine powder industry, the requirements for non-metallic products are getting higher and higher, especially for the fineness of the products. Therefore, Raymond mill with high output and low energy consumption is more and more popular among customers.

Raw materials of Raymond roller mill

Raymond grinding mill is widely used to grind the calcite, limestone, talc, quartz, gypsum, feldspar, marble, wollastonite, bentonite, manganese ore, phosphate ore, ilmenite, mica, kaolin, rare earth, dolomite, barite, graphite and other non-flammable and non-explosive materials with hardness below 7 on Mohs scale and humidity below 6%.

Wide applications of Raymond mill

Raymond bowl mill is mainly used in metallurgy, construction, mining, chemical industry, road building and other industries. Specifically, the powder it produces can be used as inorganic filler in putty powder, double fly powder, paint, coating, power plant desulfurization powder, plastic filling, toothpaste, paper making and other products.

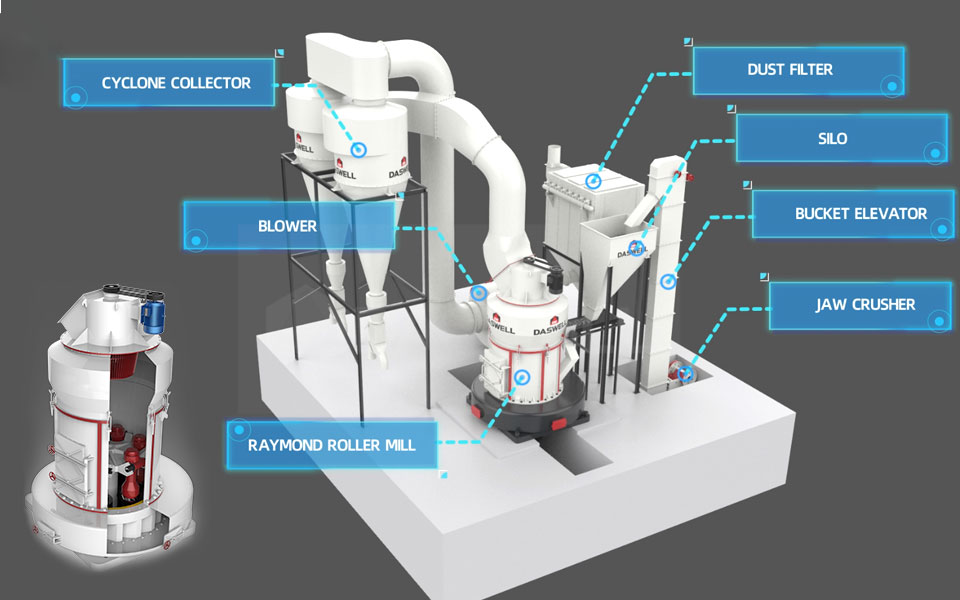

Working flowchart

Raymond mill production line is generally composed of main machine, seperator, blower, cyclone dust collector, motor and so on. The auxiliary equipment includes jaw crusher, bucket elevator, vibrating feeder, electric control cabinet, etc.

Users can choose different configurations flexibly according to the site situation. If your material does not meet the feeding size, we can configure the corresponding crusher for you before feeding. First crush the material to the right size and then feed it with the elevator.

Among them, the main machine is composed of frame, shovel, grinding roller, grinding ring, housing and motor.

How does a raymond mill work?

Firstly, after the crusher machine crushes the large pieces of material to the required feed size, the bucket elevator conveys the material to the storage bin. Then the vibrating feeder evenly delivers the crushed material to the grinding chamber of the main machine. Then the blower blows the air from the dividing plate into the grinding chamber and sends the crushed powder to the analysis chamber.

The adjustable-speed motor drives the rotating analysis impeller for sorting through the transmission device, and the large particles fall back to the grinding chamber for regrinding. And the qualified fine powder enters the finished cyclone dust collector with the airflow and is discharged from the discharge port as the finished product.

The shovel plays a very important role in the working process of the main machine. It is located at the lower end of the grinding roller, and in the process of rotation of shovel and grinding roller, the shovel is to shovel up the material into the grinding roller between the roller ring, forming a bedding layer. The material layer is crushed by the outward extrusion pressure generated by the rotation of the grinding roller, thus achieving the purpose of grinding. You can use it for your quartz powder processing plant.

Raymond mill advantages

1.The fineness of the finished powder is uniform, and the sieving rate can reach 99%, which is difficult to be achieved by other grinding equipment.

2.The electrical system is centrally controlled, so the workshop can be operated unmanned, which is safer and more convenient.

3.The transmission device of the host adopts a closed gear box and belt pulley, with smooth transmission and reliable operation.

4.The Raymond pulverizer adopts a vertical structure and occupies a small area. It forms an independent production system from the rough processing of raw materials, transportation, grinding to packaging.

5.The important parts of Raymond mill are made of high-quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation.

6.It adopts large shovel knife to send the material to the middle of the grinding roller and grinding ring for grinding to the maximum extent. The shovel knife is made of alloy steel, which is durable.

7.Large grinding area. The increased height of the grinding rollers and rings allows the mill to have a larger grinding area.

8.High grading precision. Adopt large grading turbine, high passing rate and large processing air volume.

9.New type of grinding roller device. The grinding roller device adopts new maintenance-free structure with reliable and sealing. Its bearings are lubricated by engine oil, with low oil consumption and low maintenance cost.

10.Our Raymond vertical mill adopts high pressure fan, which increases the air volume and air pressure and greatly improves the pneumatic conveying capacity.

11.The residual air is collected by cloth bag, no dust pollution. The noise is also low.

Some questions you need to know before buying a Raymond mill

Before you plan to buy a Raymond fine grinding roller mill, you need to think about the following questions in order to buy a suitable grinding machine:

1.What type of material do you need to process? In other words, what are your raw materials?

2.What is the maximum size of the material you process?

3.What are your requirements for discharge size?

4.What is the output per hour of Raymond roller mill you need?

5.Do you have any additional requirements for the configuration of the whole line?

Technical parameter of Raymond roller mill

Where to buy raymond mill?

If you search for Raymond mill manufacturers in your browser, you will find many results. If you are in an area where a reliable Raymond mill manufacturer is located, you can choose to buy from the local area because it will save you the cost of transportation.

But if you can’t find a suitable manufacturer in your local area, choosing to import a Raymond mill is not a bad choice.

When you choose a foreign manufacturer, you need to determine if the Raymond mill manufacturer is trustworthy:

- Check the strength of the manufacturer to see if they have rich production experience and whether the product quality is reliable.

- See if their sales staff and engineers are professional in the whole trade process. Can they solve your problem?

- Find out what kind of after-sales service they can provide? What are they going to do when there is a problem with the machine during use?

- Refer to the evaluation of their previous customers to see if the previous customers are satisfied with their products and services? If convenient, it is better to visit the customer’s site to see the operation of the machine.

FAQ of Raymond grinding mill

Q:How many grinding rollers are installed in the 3R model Raymond mill?

A:If our 3R model mill is to grind softer materials, such as heavy calcium carbonate, it is usually equipped with three grinding rollers, so the output is higher than that with four grinding rollers, because there is enough space inside the Raymond pulverizer for air circulation. But if we want to grind hard materials, such as silicon powder, then we will equip four grinding rollers, because it is more difficult to grind hard materials, and if we equip four grinding rollers, the output will be higher. These are the results of our actual calculations.

Q: Is your dust collector equipped with simple bag dust collector or pulse dust collector?

A: We can equip you with a bag dust collector or a pulse dust collector according to your requirements. The dust collection efficiency of the bag dust collector is not as high as that of the pulse dust collector. However, if the local environmental requirements are not too high, you can choose the bag dust collector because the price is relatively cheap. If there are certain requirements for environmental protection, you can use pulse dust collector.

Q: I want to produce 25 micron heavy calcium carbonate powder, can I use Raymond roller mill?

A: If you mainly produce D97, 25 micron powder or coarser products, you can choose to use Raymond mill, our 3R1000 and 3R1224 can be used to produce 23-180 micron powder. But if you want to produce D97, 25 micron and finer powder, for example, you also want to produce 10 micron, 15 micron and other fine powder, we suggest you to use our micro powder roller mill.

Technical Data:

| Model | 3R1000 | 3R1224 | 4R1630 | 4R1730 | 4R1830 |

| Roller quantity(piece) | 3 | 3 | 4 | 4 | 4 |

| Max. feeding size(mm) | 20 | 20 | 30 | 30 | 35 |

| Product size(µm) | 25-198 | 25-198 | 38-198 | 38-198 | 45-198 |

| Capacity(t/h)(based on different raw material fineness) | 1-7 | 2-14 | 2.5-24 | 3-25 | 6-30 |

| Roller ring outer diameter(mm) | Φ970 | Φ1280 | Φ1620 | Φ1700 | Φ1850 |

| Total power(kw) | 97 | 145 | 264 | 322 | 417 |