Ball Mills

The calcium carbonate powder produced by the ball milling production line can play the role of filling, reduce the cost of materials, and at the same time improve the hardness and whiteness of the product.

The ultra-fine calcium carbonate ball mill plant is a new energy-saving and efficient grinding production line that combines the self-dividing flow micro-powder classification technology with the ultra-fine ball milling technology. Its raw materials include calcium carbonate (calcite, marble, limestone, chalk), kaolin, bauxite, dolomite, barite, quartz, etc. The calcium carbonate powder produced by the ball milling production line can play the role of filling, reduce the cost of materials, and at the same time improve the hardness and whiteness of the product.

Working process of ball mill plant

As shown in the video, we can see the complete ball mill production line workflow.

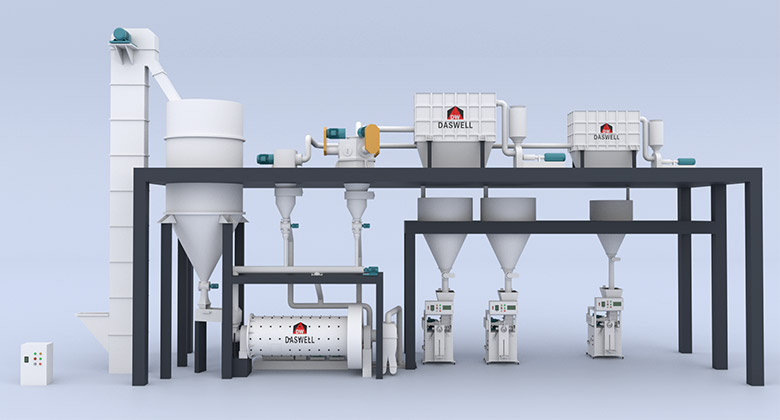

First, the material reaches the feeding size after two-stage crushing, and is lifted into the raw material silo by the elevator. Then it is fed into the ball mill through the quantitative weighing belt feeding device. The materials are crushed by the continuous impact of the grinding balls in the ball mill machine. The ground powder enters the classifier with the airflow for classification. After classification, the fine powder enters the high-pressure pulse dust collector together with the airflow for one-time collection. Then the finished product is discharged to the finished product warehouse for storage, and the packaging machine is packaged.

The classified coarse powder can be returned to the feed end of the ball mill to be mixed with the raw materials and then entered into the ball mill for grinding. A closed-loop processing system can be formed. The coarse powder under classification can also be subjected to secondary classification. By extracting the fine powder and reducing the amount of fine powder to be ground, it can increase production, save energy and reduce consumption, and produce powder products with suitable particle size. Daswell has complete calcium carbonate powder making plant, quartz powder processing plant, and so on. According to your different requirements, we can customize for you.

What is advantage of ball mill plant?

- Our heavy calcium grinding and grading technology, equipment and control technology all belong to the world’s advanced level, especially suitable for the production of D97, 5-45 microns powder.

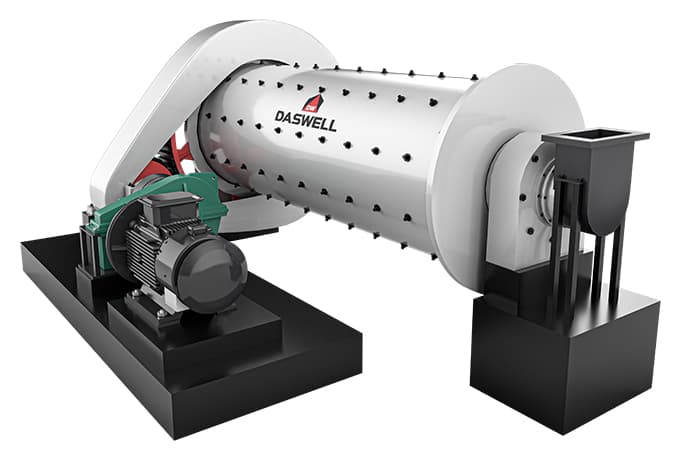

- The ball mill can be customized and equipped with replaceable wear-resistant linings to prolong the service life of the ball mill for sale.

- The classifier can easily classify -5μm ultra-fine products, and the cutting particle size is precise, and high-definition micro powder can be obtained.

- The product granularity control is flexible, and the chain control is adopted to ensure stable feeding and can be adjusted at any time.

- Quantitatively add grinding aids to the ball mill through a metering pump to improve grinding efficiency and product performance stability.

- The China calcium carbonate ball mill plant is equipped with instruments such as air volume and air pressure, and accurate records ensure efficient and stable production.

- Protect the environment, ensure the lowest dust emission and reduce environmental pollution.

- The product has a high fine powder content and a well-proportioned particle shape.

- Automatic control of equipment operation, good stability, simple operation and easy maintenance.

Best calcium carbonate ball mill plant

We are a calcium carbonate ball mill plant factory with over 30 years of work experience in this industry, and are at the leading domestic level in the grinding and grading technology of ball mills.

We can screen and evaluate the raw materials to see if the raw materials can meet the requirements of ball mill production. The samples can also be inspected and processed, and the solution that best meets the needs of customers can be customized according to the characteristics of the raw materials. In addition, from ore mining, equipment layout, to the packaging of end products, laboratory testing, site selection, plant construction, we will also provide customers with good consultation, so that customers can get the best service and return.

At the same time, we can provide services for the transformation and upgrading of production lines in order to meet market demands. For our old customers, along with our product technology upgrades, we will also update the relevant information to our old customers in a timely manner. Customers can also choose to upgrade the original production line.

How to choose the ball mill?

The selection of grinding plant ball mill is based on product quality, fineness, raw material properties, site conditions and specific requirements.

The selection of ball mills is customized according to mineral hardness, grindability, product particle size distribution requirements and output. And with different proportions of grinding media, the grinding efficiency of the ball mill is maximized and the energy consumption of the product is reduced. According to different materials, the corresponding lining plate and grinding medium can be selected to ensure the purity and whiteness of the product.

If you plan to invest in grinding ball mill, you can tell us your production requirements, mineral types, particle size distribution of finished products, investment budget and other production information. Our engineers will customize the ball mill production line solution that best meets your production needs!

Ball mill production line case

Daswell has specialized in the production of grinding equipment for more than 30 years, and has exported to many countries with rich experience. The scale of the heavy calcium ball mill production line we can design can be as small as 10,000 tons/year and as large as 500,000 tons/year. Multiple product particle sizes can also be produced at the same time. Through the optimized combination of ball mill and classifier, it can ensure the lowest energy consumption, the best particle size distribution, and the most suitable market demand.

The following is a picture display of the on-site work of our exported ball grinding mill. If you want to get the ball mill production line solution case that best meets your production requirements, please contact us!

Application of calcium carbonate ball mill plant

The heavy calcium produced by the ball mill production line can be used in papermaking, plastics, rubber, ink, chemical building materials, sealing materials, daily chemicals, etc. Calcium carbonate powder mainly plays the role of filling, reducing the cost of the material, and at the same time improving the hardness and whiteness of the material. The finished powder produced by the ball mill production line has a wide range of applications. It is friendly to the downstream market and has broad investment prospects!

After-sale service

Our company will provide customers with services such as technical consultation, process design, equipment installation guidance, equipment debugging and personnel training before and after equipment delivery.

Strong technical and experienced after-sales maintenance service engineers provide all-day uninterrupted technical services.

During the warranty period, the damage caused by human causes will be repaired by us, and the materials and accessories used in the repair are only charged at the cost price. Our company is solely responsible for repairing or replacing any problems or damages caused by non-human reasons.

We have ample supply of accessories. Prevent the operation and production of customer equipment from being delayed due to lack of accessories.

The engineering and technical documents, drawings and operation manuals of all equipment and instruments provided by our Daswell machinery can meet the needs of customers for operation inspection, adjustment and maintenance during use.

The process parameters we provide are accurate and reliable, which can ensure the continuous and stable production of the calcium carbonate ball mill plant, and the indicators meet customer requirements.