Self Loading Concrete Mixer

Mix more concrete in less time – All-in-One Concrete Mixing Solution

Self-loading concrete mixer is a mobile device that mixes more concrete in less time, automatically completing the entire process of loading, mixing, transporting, and unloading. It’s like a small concrete mixing plant on wheels.

It’s highly sought after in concrete construction projects for its increased efficiency and cost savings.

Key Features of the Self-Loading Concrete Mixer Truck

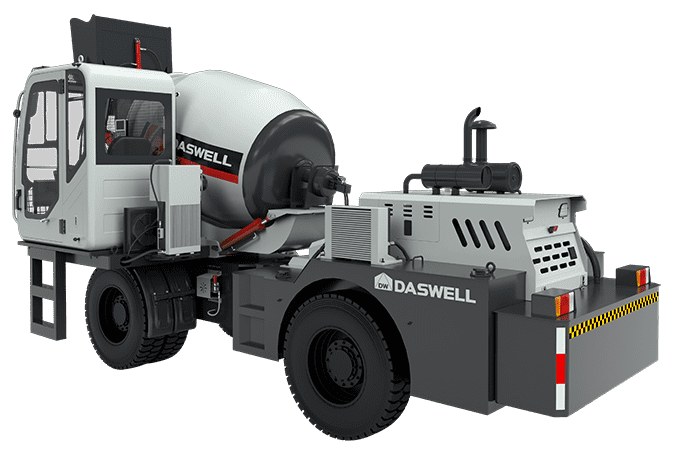

The Daswell self-loading concrete mixer truck is designed for efficient concrete production on concrete construction sites. Its compact design, narrow body, and short wheelbase ensure excellent maneuverability, even in narrow or rough terrain, while the four-wheel drive system provides strong traction and stability.

The self-loading concrete mixer truck features a 270-360° rotating mixing drum, allowing for unloading from multiple angles without repositioning the vehicle, thereby saving time and effort. An integrated weighing system ensures precise batching for consistent concrete quality, while a hydraulic loading bucket allows for quick and easy automated scooping and loading of aggregates.

Furthermore, to ensure operator comfort and safety, the truck features a fully enclosed cab and easy controls, making operation simple, safe, and efficient. This integrated design transforms the self-loading concrete mixer truck into a truly mobile concrete batching solution.

Self Loading concrete Mixers Technical Data:

| Model | SLDM1200 | SLDM1800 | SLDM2600 | SLDM3500 | SLDM4000 | SLDM5500 | SLDM6500 | |

| Mixer drum | Mixer drum(L) | 1700 | 2740 | 3000 | 4740 | 6000 | 7800 | 9000 |

| Output capacity(m³) | 1.2 | 1.8 | 2.6 | 3.5 | 4 | 5.5 | 6.5 | |

| Mixer drum rotation speed (rpm) | 13 | 13 | 13 | 13-20 | 18-21 | 20 | 16.5 | |

| Vehicle | Overall dimension (mm) | 7300*1800*3450 | 7300*2650*3750 | 7860*2750*4100 | 7730*2700*4180 | 7640*2870*4750 | 8450*3100*4580 | 8450*3050*4830 |

| Wheel base (mm) | 2560 | 2600 | 2800 | 2650 | 2480 | 3350 | 2850 | |

| Curb weight (kg) | 4920 | 6500 | 7000 | 7661 | 9000 | 11200 | 12520 | |

| Drive form | Torque converter | Torque converter | Torque converter | Torque converter | Torque converter | Torque converter | Torque converter | |

| Max. speed (km/h) | 30 | 30 | 30 | 30 | 35 | 42 | 40 | |

| Max. gradeability (°) | 30 | 30 | 30 | 30 | 45 | 45 | 45 | |

| Min. turning radius (mm) | 4700 | 5300 | 5300 | 5300 | 4800 | 6200 | 4800 | |

| Min. ground clearance (mm) | 280 | 380 | 380 | 380 | 330 | 380 | 350 | |

| Diesel Engine | Power | 55KW | 78KW | 78KW | 91KW | 91KW | 110KW | 92KW |

| Oil tank | Volume (L) | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

| Water supply system | Water tank (L) | 400 | 500 | 500 | 620 | 780 | 860 | 1465 |

| Water supply | Time relay | Time relay | Time relay | Time relay | Time relay | Time relay | Time relay | |

All-in-One mixer

With four integrated functions—loading, weighing, mixing, and discharging—this machine greatly improves efficiency, reduces labor, and ensures consistent concrete quality on-site.

1️⃣: Loading

The self-loading concrete mixer is equipped with a loading bucket and weighing function, which can automatically load and weigh the required raw materials (cement, aggregates, and water) into the mixing drum according to the optimal mixing ratio.

2️⃣: Mixing

Once loaded, the drum rotates at a designated mixing speed to ensure a uniform, high-quality concrete mixture.

3️⃣: Transporting

The mixer is self-driven and can transport the mixed concrete directly to the construction site or pouring location.

4️⃣: Discharging

Upon arrival, the machine discharges the concrete through an integrated chute or other mechanisms, ensuring efficient and precise placement.

Self Loading Concrete Mixer Detailed Structure

For your concrete mixing requirements, Daswell self-loading concrete mixer is suitable for you with high efficiency and affordable price. Besides, if you have requirements on some other concrete machinery, you can also send inquiry to us.

Advantages Over Traditional Concrete Mixers

|

Function |

Traditional Setup |

Daswell Self-Loading Mixer |

Advantage Summary |

|---|---|---|---|

|

Loading |

Saves cost, space & operator | ||

|

Weighing |

Ensures accurate mix, easy operation | ||

|

Mixing |

Flexible mixing anywhere | ||

|

Transporting |

Avoid waste and increase convenience | ||

|

Discharging |

More control, less waste | ||

|

Operator Need |

Saves labor | ||

|

Mobility |

Ideal for remote or scattered job sites | ||

|

Cost |

Fast ROI, long-term savings |

If you’re looking to streamline your concrete production with a more efficient and convenient solution, the Self-Loading Concrete Mixer from Daswell Machinery is your ideal choice.

At Daswell, we specialize in providing reliable, high-performance self-loading mixers that simplify the entire mixing process—from loading to discharging. With decades of experience in manufacturing and global service, we understand the demands of on-site construction and deliver machines that are durable, easy to operate, and ready to perform in tough conditions.

We offer:

Contact us today to get a personalized quote or schedule a demo.

Let Daswell help you make your concrete operations faster, smarter, and more cost-effective.

Why choose Daswell as your self loading concrete mixer supplier?

High-Quality Mixing Solutions from Daswell

Daswell specializes in manufacturing premium machinery. We offer two advanced automatic self Loader concrete mixer types: flat-mouth and drum-style designs. Our comprehensive product range delivers exceptional quality and performance to meet diverse needs.

Flexible Pricing Options

Daswell self Loader concrete mixer machine pricing varies based on configurations and drum capacity specifications. Our newest self-loading concrete mixer starts at approximately $10,000 for the smallest model. Please note this is a reference price—final costs will be tailored to your specific production requirements, budget, and preferred configurations.

Competitive Price Proposition

We supply self-loading transit mixers at competitive factory-direct prices. Meanwhile, our company ensures both affordability and timely delivery. Contact us today to receive the latest price list and discover the perfect solution for your needs.

Customer-Centric Service

At Daswell, we offer you advanced equipment with outstanding service. Our technical experts will help you choose an ideal model and configuration for your operations.

For your specific requirements, just contact our sales manager.

Performance advantages of Daswell mini self loading concrete mixer

Except for the rural roads, these automated mixers perform well in diverse infrastructure projects:

- Trenching and slope stabilization

- Foundation work

- Bridge and tunnel construction

- Residential building projects

Daswell self loader concrete mixing truck provides continuous concrete supply with remarkable efficiency. And it should be mentioned that the self loading type mixers offer both cost savings and consistent quality across all applications. Are you interested? Get in touch with Daswell Factory.

Daswell Complete Support Services for Your Self-Loading Concrete Mixer Investment

Pre-Sale Consultation Services

Before you purchase, our Daswell business managers provide expert guidance on:

- Detailed technical specifications of self-loading mixer trucks

- Transparent payment options and financing terms

- Competitive price quotations with breakdowns

- Accurate production timelines and delivery schedules

For your specific project requirements, Daswell team will recommend the optimal mixer model for you. It can be ensured that you will get the most cost-effective solution for your operations from Daswell company.

Dedicated After-Sales Support

We can handle all logistics to ensure safe, timely delivery to your specified location worldwide. Purchaing Daswell concrete mixer self loading truck, you can get professional after-sale support:

Professional Installation Guides

24/7 Ongoing Support

Worry-Free Maintenance

If you have any doubts about the complete after-sales service terms, please contact our team.