concrete batching plants

Daswell offers a full range of concrete batching plants designed to meet the diverse needs of construction projects. Whether you’re operating in urban areas, remote locations, or need flexibility between job sites, our concrete batching plants deliver efficient and consistent concrete production.

concrete plant

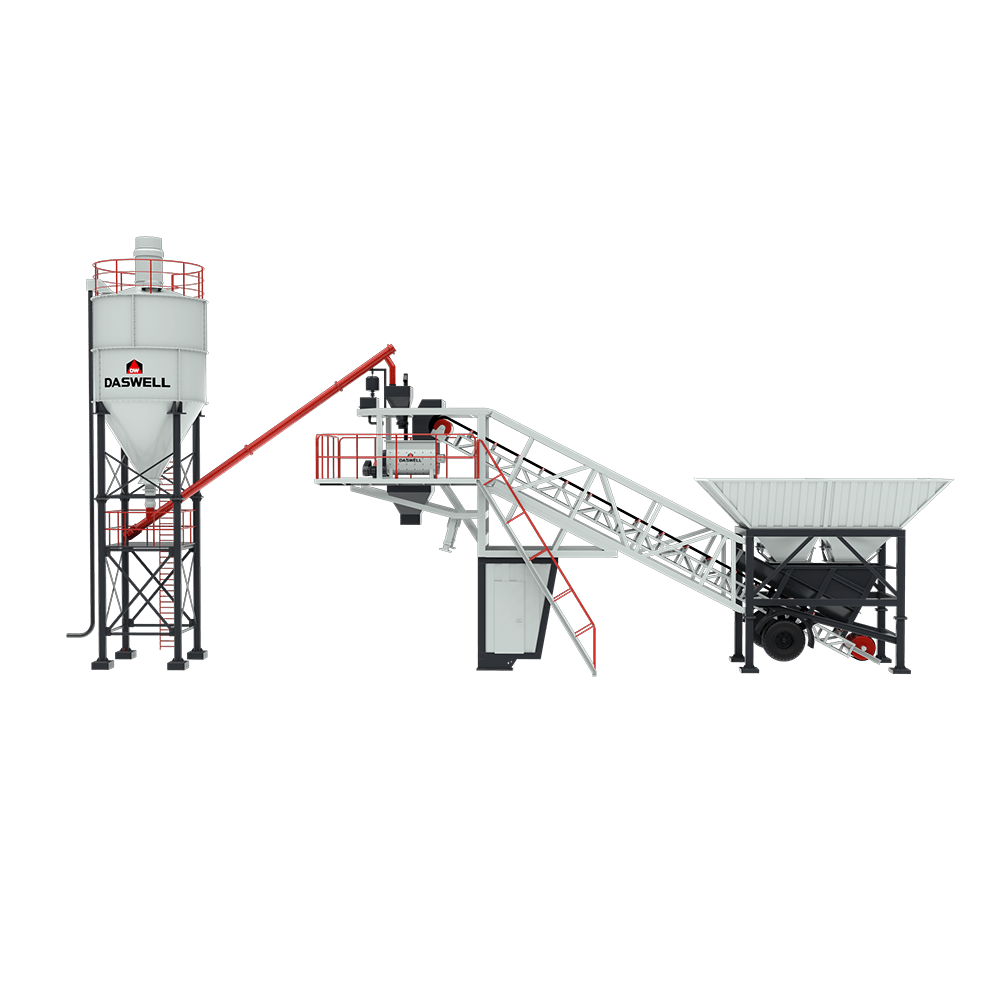

Our mobile concrete batching plants are the top choice for contractors who need fast setup, easy relocation, and reliable output. These compact and portable units reduce foundation work and installation time, making them ideal for roadworks, bridge construction, and temporary projects.

We also provide stationary batching plants for large-scale, long-term operations that require high output and automation.

With customizable configurations, automatic control systems, and robust design, Daswell concrete batching plants are built to maximize productivity while minimizing cost and downtime.

What is concrete batching plant meaning?

Concrete batching plant is a set of concrete facilities, which combines various ingredients to produce concrete. These ingredients include cement, water, aggregates( sand, gravel, or crushed stone), and admixtures. Using concrete batching plants can ensure precise proportions, uniform mixing, and efficient production for different construction projects. Generally, there are stationary concrete batching plant and mobile type plant.

What are concrete batching plant types?

Stationary concrete batching plant adopts fixed installation method. It has high production capacity between 60m³/h to 240m³/h. It is ideal for large-scale, long-term projects. For example, for your highways, dams,and urban constructions, this stationary type batching plant is applicable.

Mobile concrete batching plant is smaller and more easier for installation than stationary type. It is portable and compact. It can be mounted on trailers or skids. For your remote or temporary projects, it is suitable. The capacity is about 25m³/h-75m³/h. Its biggest advantages is that you can set up it quickly and conveniently. This makes it relocate easier.

Top 9 benefits of using concrete batching plant

Producing consistent and high-quality concrete: The concrete batching plant can mix precisely. Our batching plant can batch the materials automatically for ensuring exact proportions of cement, aggregates, water, and additive. This eliminates human error. And the concrete mixing machine can make sure every batch meets the required concrete grade.

Improving efficiency and productivity: Using Daswell concrete batching plants for concrete production, the production speed will be faster. Our concrete plants can produce 25-240 cubic meters per hour, highly shortening your project timelines. Especially, for your large projects, which need non-stop concrete delivery, the concrete plants are ideal. And the automation minimizes manual work, cutting labor costs.

Saving cost in long running: Utilizing Daswell concrete batching plants, there will be lower material waste. The precise measurements reduce cement and aggregate wastage. Meanwhile, it reduces rework. The high-quality concrete minimizes structural defects and repairs.

Meeting your various requirements on concrete: Our batching plant can produce high-strength, fiber-reinforced, or self-compacting concrete. And our planetary mixer can make higher-grade concrete than the twin-shafts mixing machine.

Environmentally friendly operations: Our plants adopt dust collectors and enclosed systems. It realizes excellent dust and pollution control. Besides, these modern plants operate with minimal noise. You do not need to worry about the noise pollution.

Easy mobility and installation of mobile plants: Mobile plants can be installed in 1-2 days. And it is ideal for remote sites. For your road projects, rural construction, and temporary sites, the mobile batching plants are perfect. Especially, there are no permanent foundation needed, saving your time and costs on civil works.

Enhancing safety and reducing manual labor risks: The automatic concrete batching plants need less manual handling, reducing accidents. The automated controls help operators manage mixing from a safe distance.

Applicable for different project sizes: Whether for your small or large scale projects, Daswell has suitable concrete plants for you. And the production capacity are adjustable. You can increase or decrease the output as you need.

Long-term durability and ROI: Daswell concrete batching plants have long lifespan. With proper maintenance, the plants can last decades. We provide high-quality concrete equipment with professional after-sale service, making sure smooth running for your project, decreasing the downtime. And it also helps speed up construction, improving ROI.

Investing in a concrete batching plant, offers you quality, efficiency, cost savings, and environmental benefits. It is indispensable for modern construction. Whether you need the stationary or mobile batching plant, it highly improves your production efficiency. Just contact Daswell for getting the best prices.

How to choose suitable concrete batching plants for you projects?

Daswell has two types of concrete batching plants for your concrete constructions. The stationary concrete batching plants have higher output capacities. The mobile type is more suitable for temporary projects. It is key for you to selecting the best concrete batching plant for efficiency, cost control, and quality output. Here you can know more details of the different batching plants for selecting the most suitable plant for your project.

Projects size and duration: For your large scale projects, including dams, highways, and high-rises, the stationary concrete batching plants will be suitable. They has high capacity for your long-term use. The mobile or compact plants are easier to relocate. Thus, for your small and medium projects, the mobile type portable batching plant is more suitable. You can use it for residential buildings, roads, etc.

Required concrete output: Generally speaking, for your high output capacity requirement, we will recommend the stationary concrete plant. There are skip hopper type and belt conveyor plant for your stationary plants needs. The biggest capacity of belt conveyor concrete batching plant can be 240 m³ per hour. For your small output capacity requirement, you can choose our mobile type, the smallest capacity is 25m³ per hour. It is more economic than the stationary type.

Types of concrete needed: If you want to produce standard ready-mix concrete, the common plants are available. We choose twin-shafts concrete mixer for mixing the concrete. It can mix the materials uniformly. However, for your high-grade concrete production requirement, there are planetary concrete mixing equipment for you.

| Model | MCBP25 | MCBP35 | MCBP50 | MCBP75 | MCBP100 | |

| Capacity (m3/h) | 25 | 35 | 50 | 75 | 100 | |

| Concrete mixer | Model | TCM500 | TCM750 | TCM1000 | TCM1500 | TCM2000 |

| Mixing power (kw) | 18.5 | 30 | 18.5×2 | 30×2 | 37×2 | |

| Output per batch (m3) | 0.5 | 0.75 | 1 | 1.5 | 2 | |

| Max. aggregate size | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | |

| Aggregate bin (m3) | 2×8 | 2×8 | 4×8 | 4×8 | 4×10 | |

| Walking speed (km/h) | 20 | 20 | 20 | 20 | 20 | |

| Weighing accuracy | Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Additive | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Discharge height (m) | 3.8 | 3.8 | 4.0 | 4.0 | 4.0 | |

| Total power (kw) | 40 | 55 | 75 | 105 | 135 | |

| Model | CBP25 | CBP35 | CBP50 | CBP75 | |

| Capacity (m³/h) | 25 | 35 | 50 | 75 | |

| Mixer | JS500 | JS750 | JS1000 | JS1500 | |

| Aggregate Bin | PLD800 | PLD1200 | PLD1600 | PLD2400 | |

| Discharge Height (m) | 3.8 | 3.8 | 3.8 | 3.8 | |

| Cycle Time (s) | 72 | 72 | 72 | 72 | |

| Weighing Accuracy (%) | Aggregate | ±2 | ±2 | ±2 | ±2 |

| Cement | ±1 | ±1 | ±1 | ±1 | |

| Water | ±1 | ±1 | ±1 | ±1 | |

| Additive | ±1 | ±1 | ±1 | ±1 | |

| Model | CBP60 | CBP90 | CBP120 | CBP180 | CBP240 | |

| Capacity (m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Mixer | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | |

| Aggregate Bin | PLD1600 | PLD2400 | PLD3200 | PLD4800 | PLD6400 | |

| Discharge Height (m) | 4 | 4 | 4 | 4 | 4 | |

| Cycle Time (s) | 60 | 60 | 60 | 60 | 60 | |

| Weighing Accuracy (%) | Aggregate | ±2 | ±2 | ±2 | ±2 | ±2 |

| Cement | ±1 | ±1 | ±1 | ±1 | ±1 | |

| Water | ±1 | ±1 | ±1 | ±1 | ±1 | |

| Additive | ±1 | ±1 | ±1 | ±1 | ±1 | |

Why choose Daswell concrete batching plants?

Superior engineering and build quality: Daswell use premium-grade steel for durability. Our concrete batching plants have robust construction. And we manufacture concrete equipment with precision manufacturing, ensuring long service life.

Wide range of plant configurations: We have stationary and mobile concrete batching plant for your different projects. Besides, for your different mixing needs, there are different concrete mixers as well.

Advanced automation technology: We utilizes intelligent PLC control systems for precise batching. And the touch-screen interfaces are user-friendly.

Energy-efficient and eco-friendly designs: The low power consumption systems reduce operating costs. And we utilize effective dust collection for environment. The noise reduction technology is also compliant with the urban.

Global support and service network: Our concrete machinery have been sold to various countries. Moreover, we have many local branches in many countries such as Philippines, Indonesia, Mexico and so on. And there are complete spare parts inventory for minimal downtime. We can offer you 24/7 technical assistance for quick maintenance support.

How much does a concrete batch plant cost?

Concrete batching plants prices are the most concerned question when you are planning to buy a concrete batching plant. As a professional concrete machinery manufacturer, we can provide you high-quality machines at good price. And the after-sale service makes sure your projects running better. It is economical to choose Daswell concrete batching plant for long term.

The mobility, capacity, and the configurations are key factors, which influence the concrete batching plant prices. For example, the larger capacity has higher price than the small capacity. For your reference, the CBP 120 with common configurations price is 140000 dollars. It is higher than the CBP 60. With the same output capacity, the mobile type concrete batching plant is more expensive than the stationary type. Because the mobile type concrete batching plant can be moved and disassembled easily. It is more convenient than the stationary type plant for your relocation.

Except for the capacity and mobility, the machine configurations of the whole production line also affect the prices. For instance, if you choose the twin-shafts mixing machine, the price is different from the planetary mixer plant. And the dust collector facilities also determine the price of concrete batching plants. If you want to know more details of the price of Daswell concrete batching plants, just send an inquiry to us. We will make quotation for you according to your projects scale, mobility, and equipment configurations.

Daswell offers you professional after-sale service, helping your solve the problems from installation to maintenance. We have many branches in different countries with professional engineers and spare parts stocks. You do not need to worry about any problems when operating. Our professional service can reduce your downtime. It brings you high-profit for long term.