Concrete Mixers – Types and How to Choose

The concrete mixer is a machine that mixes cement, sand and gravel aggregates, water and admixtures into concrete. It works both alone and with other devices.

There are many types of concrete mixers, which can be divided into different types according to different classification standards.

According to different mixing principles, the concrete mixers can be divided into self-falling type and compulsory mixing type. According to whether they are movable, it can be divided into mobile type and stationary type. According to the nature of work, they can be divided into intermittent type and continuous type.

This article will introduce the four common concrete mixers and how to choose the right mixer.

Drum concrete mixer

Drum concrete mixer is also called self-falling concrete mixer. The mixing drum lifts the material to a high place during the stirring process, and then the material falls down with the help of its own gravity, and the dropped material achieves the effect of uniform stirring during the rotation of the drum. The mixing drum rotates forward for stirring and reverses for discharging.

Because of its low investment cost and low maintenance cost, the drum concrete mixer is mainly suitable for small and medium-sized projects.

Depending on the power, drum mixers can be divided into two types: electric type and diesel type. In contrast, diesel concrete mixers are welcomed by more customers because they do not require an external power supply and are directly powered by diesel engines, making it more convenient to use. Generally speaking, diesel mixers are available in two models, one with a discharge of 350 liters and the other with a discharge of 500 liters.

Concrete drum mixers are generally used independently to produce concrete. Customers can choose the appropriate type and model of machines according to their actual needs.

Twin shaft concrete mixer

The twin shaft concrete mixer is a compulsory mixing machine. There are two horizontal mixing shafts inside the mixing cylinder, and the stirring blades are driven by the rotation of the mixing shafts to continuously mix the materials. The materials mixed in this way are more uniform and of better quality. In addition, the twin shaft mixer also has the characteristics of high mixing efficiency, wide application range, long service life and low failure rate.

Twin shaft mixers can generally work alone or together with other equipment. For example, it can be combined with aggregate batching machine, cement silo, screw conveyor, etc. to form a concrete mixing plant for mass production of commercial concrete. It can also be combined with aggregate batching machine, belt conveyor, block forming machine, palletizer, etc. to form a brick machine production line to produce high-quality bricks.

So, when you want to buy a twin shaft concrete mixer, you need to know its use, output and configuration. In this way, you can buy a suitable machine.

Planetary concrete mixer (Vertical shaft mixer)

The vertical shaft mixer is relative to the horizontal shaft, because its shape looks like a planet, so it is also called a planetary mixer. Planetary mixer is also a kind of compulsory mixer.

The mixing arm and mixing blade of the planetary concrete mixer are compound movements of revolution and rotation, and the mixing trajectory is complex, which can achieve a more uniform and efficient mixing effect. It is widely used in prefabricated components, concrete bridge frames, concrete walls, refractory materials, ceramics, glass and other industries.

Planetary mixer has the advantages of compact structure, low noise, good sealing, no pollution, low energy consumption, good mixing effect, etc., and is widely welcomed by European and American customers.

Similar to twin-shaft mixers, planetary concrete mixers can work alone or together with other equipment to form a production line. If you want to produce higher-quality concrete, then a planetary mixer is a good choice.

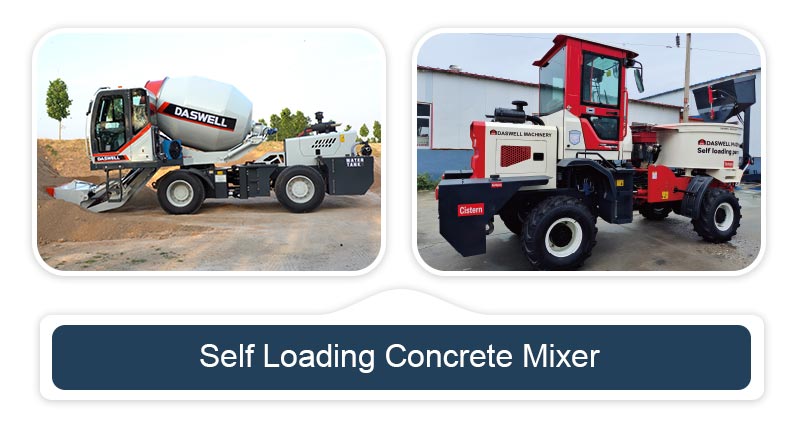

Self loading concrete mixer

Self loading concrete mixer is a new type of mixer machine. It integrates four functions of loading, mixing, transportation and unloading, which is equivalent to a small mobile mixing plant. It can be divided into self loading drum mixer and self loading pan mixer. The main difference between the two is the mixer, the former uses a drum mixer, and the latter uses a pan mixer.

Self loading mixers have played a great role in many infrastructure projects, such as road building, foundation laying, ditches building, and tunnels building. It has the advantages of narrow body, short wheelbase and small turning radius. Therefore, for projects with limited construction sites, self loading concrete mixers are an ideal choice.

In addition, its mixing tank can be rotated 270°, so it can realize unloading on all sides without moving in place, saving time and improving efficiency. Because it is easy to operate, one person can operate the whole system, saving the manpower of 3 to 5 people.

How to choose a suitable concrete mixer?

Choosing the right concrete mixer is very important. Only equipment that meets the needs of the project can ensure production efficiency and construction progress. So, what are the factors to consider when choosing a concrete mixer?

Types of concrete mixers

As we all know, there are many types of concrete mixers, the first thing you need to determine is which type of mixer you need.

If you want to produce higher quality concrete or commercial concrete, twin shaft mixers and planetary concrete mixers are an ideal choice;

If your project is not that big and the demand for concrete output is not high, you can choose a drum concrete mixer, which can reduce your investment cost;

When you need a machine that can both produce concrete and transport the finished concrete to the construction site, consider a self loading mixer truck.

Its output

After deciding on the type of mixer machine, you also need to choose the right model. This is related to the size and duration of your project. If your project is large and the construction period is long, then a concrete mixer with a large output can meet the needs of the project. Instead, you can buy a concrete mixer with a smaller output and lower your investment costs.

It should be noted that if you want your concrete mixer to work uninterruptedly, you must first ensure that the raw materials are adequately stored, and then you must ensure the speed of batching, so as to maximize the production efficiency of the mixer.

Different configurations

If the configuration is different, the same model of concrete mixer will also have different prices. So, next you need to think about the configuration of the concrete mixer machine. Taking the twin shaft mixer as an example, you need to consider its feeding method, discharging method, lubrication method, etc.

Small size twin shaft mixers generally use hopper feeding, and large size mixers generally use belt feeding. The advantage of using belt feeding is that it can be fed continuously, ensuring the continuity of production.

The discharging methods include manual discharging, pneumatic discharging and hydraulic discharging. Lubrication methods include manual lubrication and automatic lubrication.

Manufacturer’s strength and services

Finally, you also need to consider the strength and service of the mixer manufacturer. The quality of concrete mixers produced by powerful manufacturers is more guaranteed. Moreover, trusted manufacturers can provide you with better services, such as operation training, regular inspection and maintenance, and distribution of wearing parts.

To sum up, if you want to buy a suitable concrete mixer, you need to consider these factors. You can also look for a trustworthy manufacturer, and experienced engineers will give you professional advice.