Why Use Ball Mill for Quartz Powder Processing Plant?

Quartz is a hard naturally occurring minerals. The mosh is 7. It has abrasiveness and high silica content. Thus, it presents unique challenges in grinding. When you utilize the quartz for glassmaking, ceramics, foundries, and construction, the particle size and purity are critical. Ball mill grinding machine remain the dominant choice for quartz processing. Except for the ball mill, there are also ring roller mill and Raymond mill equipment in the market. Do you know why ball mill machine is the most popular one for quartz powder processing plant?

What matters the mill grinding machine for quartz powder processing?

Material hardness and abrasiveness: The mosh hardness of quartz is 7. And it has high abrasive. Thus, it needs mills, which have high-impact grinding mechanisms. And the materials of the mill machine should be wear-resistant materials. For example, the ceramic liners and high-chrome steel balls are applicable.

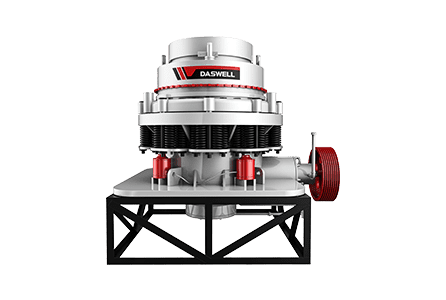

Desired particle size and fineness: Generally, if you need 20-100 mesh, Daswell recommends you the jaw crusher or cone crushing machine. These machines are mainly used for crushing big quartz ore into small size. The grinding mill machine can process these crushed quartz into fine powder. The ball mill machine can produce finer powder than other milling equipment. Meanwhile, with an air classifier, it can separate the qualified powders and unqualified powders as your requirements.

Contamination control: The iron contamination from the grinding media affects quartz purity. It is critical for glass, electronics, etc. You had better use the ceramic-lined ball mills and alumina grinding media. Daswell can meet your needs.

Ball mill machine: the best choice for quartz powder grinding

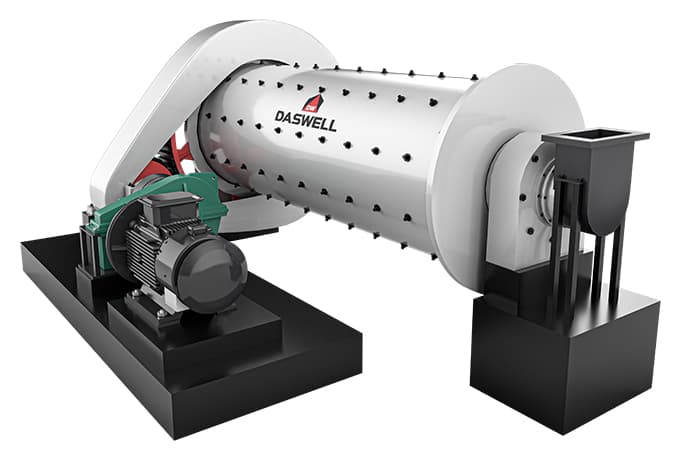

Ball mill grinding machine is the most popular grinding equipment among our customers for calcium carbonate grinding, quartz powder producing, and talc powder processing. It can produce quartz powder, which is about 5 micron and 200 micron. Especially, for making finer powder quality, Daswell can provide air classifier for you. It can separate the powder size efficiently with high accuracy. And the unqualified powder can be returned into the ball mill machines until it is fine enough for meeting your needs.

How does ball mill grinding machine work?

The ball mill facility has a rotating cylinder. When it works, the rotating cylinder filled with steel or ceramic grinding media will move by the rotating cylinder. Because of the gravity, the grinding media, the balls, will fall down and crush the quartz into fine powders. It should be mentioned that the feeding size of quartz materials should under 40mm.

Why ball mills excel for silica sand?

High-impact grinding: It is effective for hard, abrasive materials like quartz.

Applicable for wet or dry processing: Using ball mills, it is applicable for you to operate with water to reduce dust and improve efficiency.

Adjustable fineness: You can control the grinding time, media size, and the rotational speed. By controlling these, the fineness of finished quartz powder is adjustable.

Low contamination: With the ceramic-lined mills and alumina grinding media, it can prevent iron contamination.

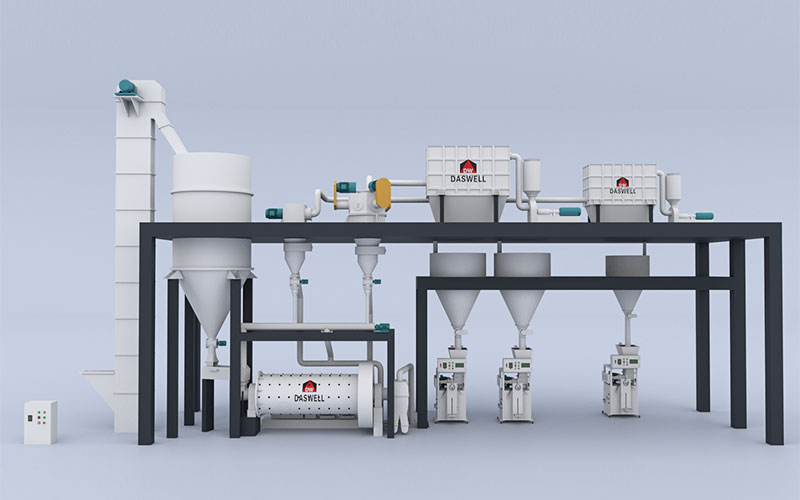

How does Daswell optimize the ball mill plant for quartz powder grinding?

Daswell Machinery is an experienced grinding mill plant supplier. And we keep improving our products for meeting customers’ needs. For maximizing working efficiency in silica sand production, Daswell optimizes our ball mill plant.

We utilize ceramic or high-chrome steel grinding media. It is helpful for reducing the iron contamination.

If you have strict requirements on the quartz powder fineness, we can offer you the air classifiers. Its main function is that it utilizes air flow and gravity for separating the qualified and unqualified powders. It is applicable for grinding the unqualified powders again until they are qualified. Meanwhile, equipping with the dust collector, it is also helpful for reducing the environmental pollution.

Both the ball mill equipment and air classifiers are adjustable. You can set according to your equipment. The fineness of finished products from ball mill grinding machine and the particle size classification can be controlled easily.

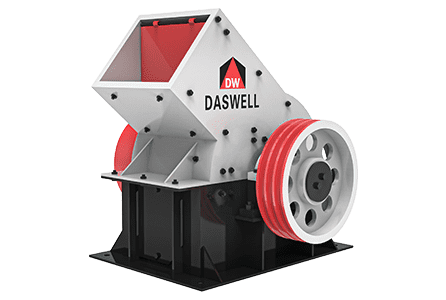

If your quartz materials are big size, which is not suitable for ball mill, Daswell can offer you crushers for reducing the size of quartz. There are jaw crusher, cone crusher and hammer crushing machines for sale. All of them are applicable for crushing quartz.

Is it suitable to use Raymond mill and ring roller mill for quartz powder grinding?

Dawell Raymond mill machines and the ring roller grinding mills are widely used in the powder grinding market. For your quartz powder processing plant, you can choose the ball mill and Raymond mills. Ring roller mill equipment is not recommended by Daswell for your quartz powder grinding. Here you can learn these three machines better for your quartz powder production business.

Ball mill machines can produce finer powders than the Raymond and ring roller mill equipment. It can produce D97, 5-200 microns silica powders. It can process materials, whose mosh hardness is under 7. According to your capacity and finished particle sizes, we can customize for you. Just send an inquiry to Daswell now. Get you own quartz powder ball milling plant solutions.

Raymond mill machines is also applicable for you to process the quartz powder. Similar with the ball mill machines, it can accept materials, whose mosh hardness is under 7. And its power consumption is lower than the ball mill grinding facility. But it is worth to mention that, its finished powder will be coarser than the ball mill. If you want to produce silica powder, whose size is about 40 to 180 micron, the Raymond mill will be suitable. Meanwhile, its passing rate can achieve 99%. It is the highest among these three mills.

As for the ring roller mill machine, it is not suitable for quartz powder production plant. The mosh hardness of the quartz is 7. While the ring roller mill grinding equipment can only process the materials, whose mosh hardness is under 5. The quartz is too hard to process for the ring roller mills. But if you need calcium carbonate powder or talc powder, it is available.

In conclusion, the ball mill grinding machine is the most suitable equipment for you to produce fine quartz powder. It is available for you to customize your ball mill plant in Daswell. Whether for the particle size or production capacity, Daswell Machinery can meet your needs. We will provide professional quartz powder ball mill plant solution for you. Besides, if you want to use the mill plant for processing other materials, just contact Daswell. There are technical engineers to evaluate the materials and mill plant. Daswell has various mill grinding machines for you to choose, we can offer you suitable equipment configurations.