How to Start A Concrete Batching Plant Business?

Starting a concrete batching plant is a profitable business opportunity in the construction industry. A concrete batching plant is mainly used for mixing cement, water, aggregates, and additives to produce ready-mix concrete for various projects.

Before you start your own batching plant, you should understand the types of batching plants: stationary batching plant and mobile concrete batching plant. And knowing their main differences and applications, it is better for you to choose the most suitable batching plant for your own business. Besides, it is also key to make proper planning, market research, and compliance with regulations for your success.

What is concrete batching plant?

A concrete batching plant is a set of facilities. You can use it to produce concrete. The batching plants are essential in the construction industry. They can provide high-quality concrete for buildings, roads, bridges, and infrastructure projects.

Generally, there are mainly two types for your business. The stationary plants have higher output than the mobile type. They are more suitable for large-scale production. The mobile plants are portable and ideal for temporary or remote job sites.

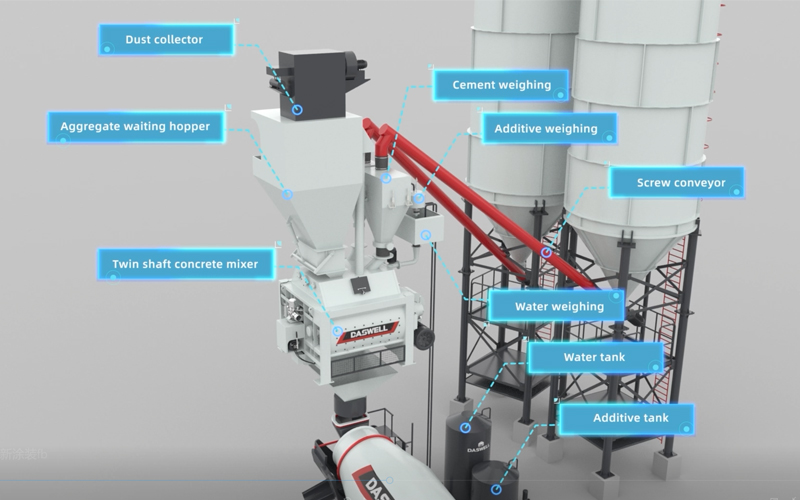

The batching process involves precise measurement and mixing of materials to ensure consistent strength and durability. Daswell concrete batching plants utilize computerized control systems for accuracy and efficiency. The main components include mixers, cement silos, aggregate bins, conveyors, and the weighing systems.

Whether for commercial, residential, or industrial projects, the concrete batch plant plays a crucial role in delivering reliable and high-performance concrete. It is wise for you to invest in an automated and well-maintained plant. It can enhance the productivity and profitability in the construction business.

Two types of concrete batching plant

There are stationary and mobile concrete batch plants for you to choose. They are mainly different in mobility and capacity. The mobile type concrete plant is portable for temporary and remote job sites. It is applicable for you to rent the mobile concrete batching plants out, because of the excellent mobility.

If you want to run a concrete batching plant for making ready-mix concrete, the stationary batching plant will be a good choice. It has higher output capacity, which can produce more concrete in every batch. But the higher the capacity, the more expensive the plants. There are various models in Daswell with different capacities for you. You can choose according to your target market, project scale, and budget.

Components of batching plant

Essential equipment for a concrete plant

In a concrete batching plant, there are several key machines, including mixers, aggregate bins, cement silos, conveyors, and control systems. The automated equipment can improve your efficiency and reduce labor costs. A mixing machine can make sure consistent concrete quality, while the cement silos store bulk cement securely. Besides, the weighing systems and water dispensers maintain accurate proportions. For your reference, the dust collectors and waste recycling systems are essential for meeting the environmental standards.

Additional required equipment

Except for the batching system, mixing system and storing systems, you can also use the wheel loader for transporting the aggregates. Daswell can provide high-quality wheel loader for you at good price. And when the concrete production processes are finished, you should transport the fresh concrete to the working site for better using. It is essential for you to use a transit truck for avoiding concrete segregation during the transportation. There are various models for you. Meanwhile, for the dust collector equipment, we have different systems for you to choose.

Legal requirements and permits

Before you launching a concrete plant, you must secure legal approvals. Generally, you should get business registration, environmental and industrial permits, and safety and labor compliance.

- Company Formation (LLC, Pvt. Ltd., Sole Proprietorship).

- GST/Tax Registration (for invoicing and compliance).

Environmental and Industrial Permits

- Pollution Control Board (PCB) Clearance (mandatory in most countries).

- Factory License (required for large-scale plants).

- Mining License (if sourcing raw materials like sand/gravel).

- Zoning and Land Use Permits (local municipal approvals).

Safety and Labor Compliance

- OSHA/ISO Standards (worker safety protocols).

- Fire Safety Certifications (for fuel and electrical systems).

Location and land requirements

It is key for you to choose the right location for running the concrete batch plant. The location will affect the production efficiency and logistics costs. Here you can know more details about it. There are four factors, which are important for the ideal sites.

- Proximity to the raw materials, such as cement, sand, aggregates is convenient for getting the materials for concrete producing.

- Good road connectivity can reduce the transport costs. Whether you are concrete manufacturer or concrete user, it will be more convenient for you. And it will be better if your batching plant near the construction sites.

- Adequate water and power supply are also important. It makes sure the whole operation of the batching plants.

- The foundation is also important. The strong, level foundation can support heavy machinery. If the ground is unstable, soil compaction or a concrete base may be necessary. Proper drainage is also essential to prevent waterlogging, which can disrupt operations.

For your reference, you should consider the land size. The mobile plant and stationary batching plants has different requirements on the land. If you do not know whether our plant is suitable for you land or not, you can contact us. And our engineer evaluates the land size, and equipment configurations, designing the plant layout for you.

Staffing and workforce

Running a concrete plant requires skilled and unskilled labor. Generally, you need two workers for operating the whole production line. One for start the PLC system, control the machines. And one for driving the wheel loader.

Training and safety are also important for your batching plant running. Daswell provides professional training for our customers. Whether for the online training, or the site training, we can meet your needs. We will make sure that the operator can operate the equipment smoothly. Meanwhile, we can also install the production line. And for the maintenance, there are many Daswell branches in different countries. We have engineer for repair the equipment. Thus, you do not need to worry about the maintenance.

Operating a concrete batching plant requires careful planning, investment, and compliance with regulations. By choosing the right location, equipment, and workforce, you can build a profitable venture. With the right strategies, your batching plant can become a key player in the construction sector.

Daswell has lots of customers all over the world. It is wise for you to choose Daswell Machinery for concrete batching plant purchasing. We can provides professional suggestions for your concrete batching plant business. And it can be sure that you can get high-quality concrete machines at good price with excellent after-sale service. Just contact Daswell, and start your own concrete batch plant business.