As an important building material, sand and gravel aggregate is widely used in the construction of houses and road projects, and the market demand is huge.

In recent years, natural sand and gravel resources have become increasingly tight, and prices have continued to rise. And after years of exploitation, natural sand resources are rapidly decreasing. In order to maintain ecological balance, governments around the world have introduced policies to limit the exploitation of natural sand. Therefore, the demand for artificial sand has gradually increased in recent years.

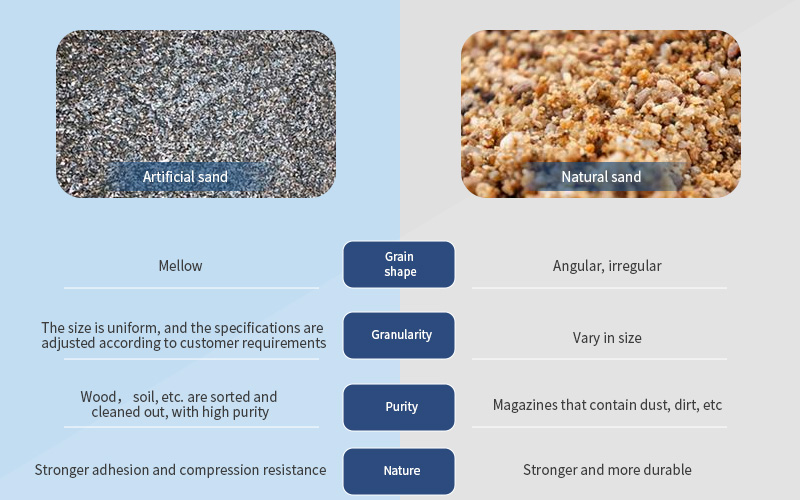

So, what is the difference between artificial sand and natural sand?

What is natural sand?

Natural sand refers to rock particles with a particle size of less than 5 mm formed by natural conditions (mainly rock weathering). It is mainly divided into river sand, sea sand and mountain sand.

River sand has a smooth surface, is relatively clean, and has a wide range of sources. It is a common basic material in construction. Most of the natural sands mentioned in this article are river sands.

What is artificial sand?

Artificial sand is formed by mechanical crushing and screening, and the particle size is less than 4.75mm of rock particles, mine tailings or industrial waste residue particles, but does not include soft and weathered particles.

Difference bewteen artificial sand and natural sand

Appearance

Artificial sand is mainly obtained after crushing by a sand making machine, with sharp edges and corners and many needle-like shapes.

Most of the natural sand is formed by the long-term impact of rivers and seawater. The sand grains are naturally formed, the edges and corners are relatively round, and there will be some pebbles and fine sand in them. Moreover, river sand is generally formed by the collection of rivers flowing through different places, and the color is more mixed.

Robustness and durability

Artificial sand has slightly less solid properties than natural sand, but still meets the standard for use. There is no problem in the use of ordinary concrete.

However, if it is used in concrete members that are often subjected to frictional impact, in addition to admixtures, the lime-sand ratio of concrete, the crushing index of sand and the content of stone powder should also be controlled.

The content of stone powder

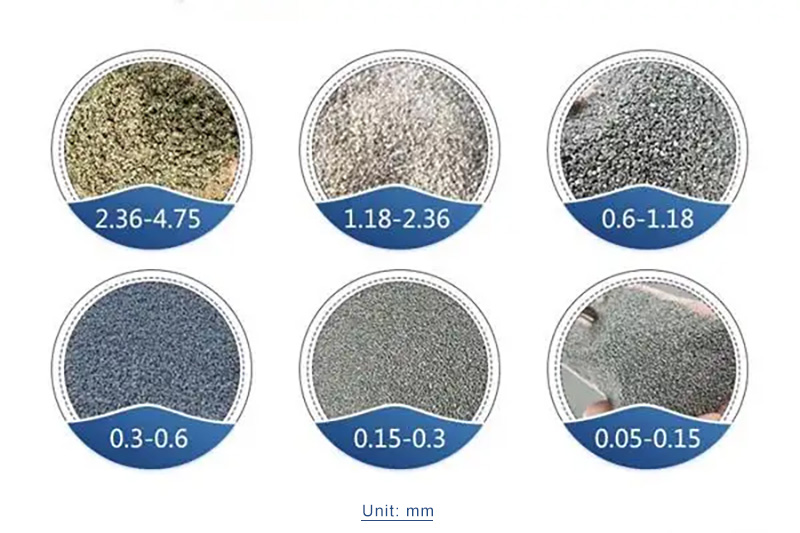

The large content of stone powder is an important feature of artificial sand different from natural sand. The stone powder mentioned here refers to particles smaller than 0.075 mm. It should be noted that the powder content in artificial sand is different from the mud content in natural sand. The requirement for stone powder content in ordinary concrete is below 10%, and for high-strength concrete below 5%.

Adhesion and compression resistance

Due to the irregular particles of artificial sand, when it is bonded with building materials such as cement, it tends to have better adhesion, more compression resistance, and longer service life.

Fineness modulus

The fineness modulus is an index indicating the thickness and type of sand. The larger the fineness modulus, the coarser the sand. The fineness modulus of sand used in ordinary concrete is 3.7-1.6, medium sand is suitable, and coarse sand plus a small amount of fine sand can also be used, and the ratio is 4 to 1.

For natural sand, one fineness modulus can have multiple gradations. For artificial sand, one fineness modulus corresponds to only one gradation. Moreover, the fineness modulus of artificial sand can be controlled artificially through the production process, and the production can be carried out according to the requirements of customers, which cannot be achieved by natural sand.

Composition

Artificial sand is generally an artificially selected raw material, the material is uniform and stable, the mineral composition and chemical composition are consistent with the raw material. And it is not as complicated as natural sand.

Quality

The raw material source of artificial sand is stable, and the production is mechanized, which ensures the stability of product quality. However, natural sand has a relatively wide range of sources, and contains a lot of sediment and impurities, which requires further analysis and processing.

Which type of sand is better for you?

When you need sand and gravel aggregates, should you choose artificial sand or natural sand?

Artificial sand is produced by crushing rocks with sand making machine. Artificial sand has good performance and can be mined and processed all year round.

Natural sand has the characteristics of smooth shape, hard texture and low mining cost, and is an ideal raw material. However, there are many kinds of raw materials of natural sand, and the reasons for their formation are also complicated, and they also contain some unstable chemical substances or harmful components.

The cost of artificial sand is higher than that of natural sand, but the post-treatment is relatively low. So using artificial sand is also a good choice.

The future development trend of artificial sand

Affected by the three factors of population increase, economic development and global urbanization, the global demand for sand and gravel aggregates is increasing. Whether it is airports, ports, or infrastructure construction projects such as roads and railways, there is a great demand for sand and gravel aggregates. However, natural sand is facing the status quo of restricting mining and protecting the environment.

The raw materials of artificial sand come from a wide range of sources. In addition to common rocks such as granite, limestone, river pebbles, marble, and basalt, construction waste can also be used as raw materials for processing artificial sand.

In addition, with the upgrading of technical processes, the sand making equipment not only has stable performance and low failure rate, but also has a short production cycle and high output, which can stably supply finished sand. At the same time, the sand making machine can also produce finished sand of different specifications according to customer needs. High-quality artificial sand can be widely used in different industries.

It is estimated that the current global sand and gravel production is about 50 billion tons. It is estimated that by 2030, global sand and gravel production will reach 60 billion tons. Therefore, the future development prospects of artificial sand are bright.

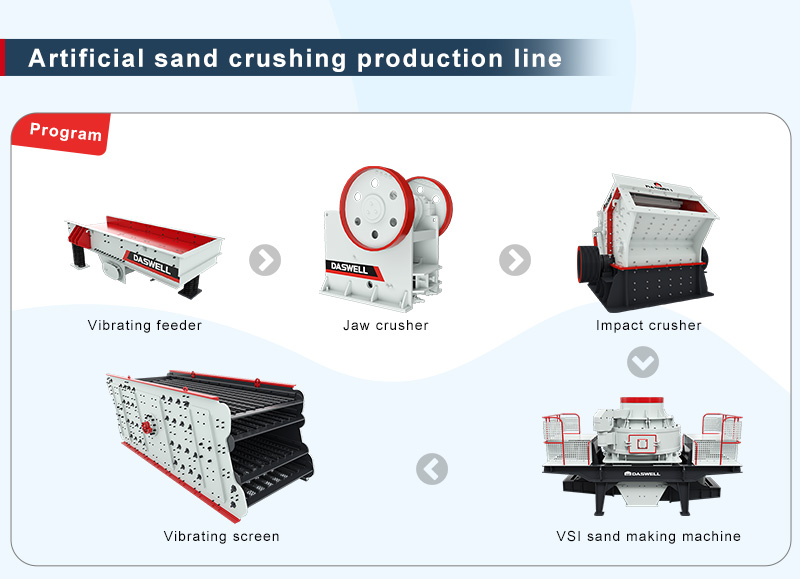

How to make artificial sand?

1.Pretreatment. If limestone, river pebbles, granite and other raw materials contain too much soil and impurities, the debris can be sorted first.

2.Crushing. Primary crushing of raw materials is carried out by primary crushing equipment. According to the different hardness of raw materials, jaw crusher or hammer crusher can be selected for coarse crushing. After coarse crushing, the materials with qualified particle size are transported to the fine crushing equipment for further crushing, and those that do not meet the requirements are returned to the coarse crusher.

3.Sand making. The materials that meet the size requirements enter the sand making machine for fine crushing and shaping. The particle size of the sand after being processed by the sand making machine is uniform.

4.Screening. The finished artificial sand is processed by vibrating screen and can be divided into coarse sand, medium sand and fine sand.

5.Cleaning. In order to improve the quality of finished sand, especially the cleanliness, the sand washing machine can be configured after the sand making process to clean the sand.

If you want to know more about construction and mining machinery, please pay attention to our website!