Home » Stone Crushers » Sand Making Machine

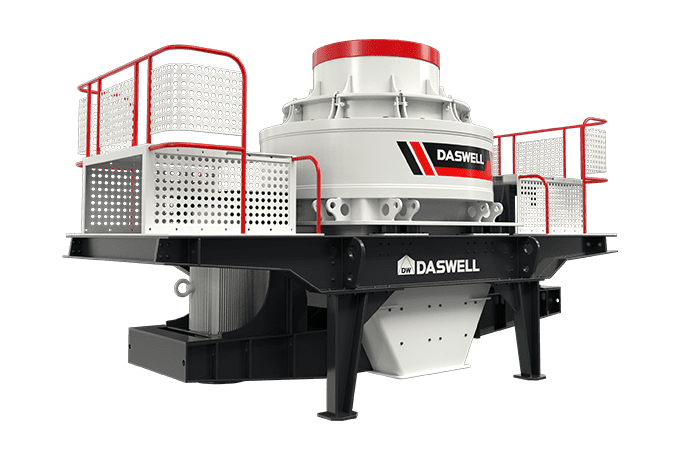

Sand Making Machine

Sand making machines are specially designed to provide high quality sand and aggregates for highways, high-speed railways, construction, hydroelectric dam construction and concrete batching plants.

What is sand crusher?

Daswell vertical shaft impact crusher is suitable for the crushing of stones with hardness not higher than 320MPa. This equipment is a professional gravel sand making equipment with high performance and stable performance developed by our company using the famous “stone hitting stone” crushing working principle and combining with foreign technology. Sand making machine for sale has the characteristics of large crushing ratio, good sand making quality, high efficiency and stability, and easy operation.

Materials for sand making machine

The artificial sand making machine produced by Daswell is widely used and can crush stones of various hardness. Such as river pebble, basalt, dolomite, limestone, gabbro, gravel, gravel, phosphate, quartzite, sandstone, iron ore, etc.

How to choose a sand making machine?

Nowadays, many sand making machine manufacturers use new technologies to develop sand making machines. Therefore, there are many different types and models of sand making machines on the market for users to choose from. So how do users choose the most suitable machine for themselves?

Engineers from Daswell can provide you with a few factors to consider, hoping to help our customers.

- The first thing to consider is the grain shape of the stone. You need to know what shape of sand you need, and we will provide you with a standard sand making machine according to your needs.

- The second point is that you need to know the post-maintenance cost of the sand making machine. Some machines are in good condition when the factory is in trial operation, but after being put into actual production, parts need to be replaced in a short time. Subsequent frequent spending will affect the interests of users.

- The third point needs to know whether the actual output of the sand manufacturing machine meets the user’s psychological expected output.

- The last point is to consider whether the price of the sand making machine meets the user’s spending budget.

Daswell Machinery has China’s leading comprehensive production strength and reputation, which can guarantee the quality of the machine and the service to customers. The machinery we produce is of good quality, with low failure rate and long service life. The price of our sand maker machine is priced according to the efficiency, cost and output of the equipment, which is professional and reasonable. If you have any questions about the sand making machine, please leave us a message, we will have a professional pre-sales and after-sales team to serve you!

What are the advantages of sand making machine in artificial sand production line?

- The unit production capacity is higher, which can realize continuous, efficient and large-scale production. It can provide high-quality aggregates for various engineering projects in a timely manner and increase income for users.

- Compared with traditional sand making plant, Daswell sand making machine has low energy consumption and high production capacity in the sand making process. In addition, the machine has high wear resistance, low replacement frequency, easy maintenance, and reduces downtime and operating costs.

- The new artificial sand manufacturing plant is equipped with a dust removal device. In the production process, there is less dust leakage and less environmental pollution, which meets the environmental protection standards of the mining industry.

- The impeller cavity is deep, and the throughput of stone materials can be increased by 30%. The output is large, and it has a certain shaping effect. The finished sand has good grain shape and reasonable gradation.

- Easy to maintain and repair. The core components of artificial sand machine are carefully built, more durable, and the life span is 1.5-3 times longer. At the same time, the hydraulic cover can be opened, which is more convenient for users to view and maintain, and the daily maintenance operation is simple.

Classification of vertical shaft impact crushers

There are two types of sand making machines produced by Daswell, VSI high-efficiency vertical shaft impact sand making machine and 5X high-efficiency vertical shaft impact sand making machine.

VSI sand making machine

VSI sand making machine has the functions of fine crushing and coarse grinding, and also has the function of stone shaping. It has good sand making effect, reasonable finished product grain shape, no crack and no tension, and low content of needle-like material, and the grain shape and gradation of sand making can be adjusted. It specializes in providing good sand and gravel aggregates for highways and railways, construction, hydropower dam construction, and concrete mixing plants. With high productivity and low consumption, VSI is an excellent choice for artificial sand making and stone shaping.

VSI sand making machine adopts the working principle of ” Stone on stone ” and “stone on iron”. “Stone on stone” is suitable for materials with high corrosiveness above medium hardness, and is suitable for material shaping. “Stone on iron” is suitable for medium-hard and less corrosive stones, and can be crushed, processed and made sand with large output. This working principle makes the VSI sand crusher more efficient in sand production and adapts to more materials.

When the VSI crusher is working, driven by the motor, the rotor runs at high speed. The material falls vertically into the high-speed rotating impeller from the feeding port at the upper end of the VSI stone sand making machine. The high-speed rotor throws the material to the impact plate in the crushing chamber. The material not only collides violently with the impact plate, but also collides and breaks with the material. Then the material bounces from the counter liner back to the blow hammer and breaks again. This process is repeated until the stone meets the standard size and falls out of the discharge opening.

5X Sand Making Machine

The 5X sand making machine is a new high-efficiency sand making machine developed by our company based on the production technology of vertical shaft impact crushing at home and abroad. It has the characteristics of energy saving, high output, high energy utilization rate and wide application.

5X sand making crusher machine is widely used in sand making plants, concrete mixing stations, desulfurization in power plants, etc. The main applicable materials are river pebble, cobblestone, granite, basalt, calcite, quartz stone, etc.

In the artificial sand making plant, the grain shape of the finished aggregate has a great influence on the strength and durability of concrete, so there are very strict standards for the machine-made sand grain shape used in concrete.

The 5X sand making machine relies on the optimized structure of the launch port and the design of the material flow curve inside the impeller, so that the final particle shape is very good. And the finished sand of 5X artificial sand making crusher has a uniform particle size, and there is almost no needle-like material. This effectively improves the quality of the aggregate, making the finished product comparable to natural sand in terms of fineness modulus, gradation, and crushing index. And the particle size of the finished product is adjustable, which can meet the different needs of users for sand making. This is also the main reason why the 5x sand making machine is very popular in the sand making industry market.