Regular and correct maintenance of concrete pumps not only ensures the efficiency and reliability of the equipment, but also increases its service life. In order to ensure the normal operation of the equipment, the operator needs to check and maintain the equipment frequently before, during and after operation. It should be noted that improper repair and maintenance will lead to damage to the concrete pump. Therefore, trained and professional operators are required for inspection and maintenance.

Daily maintenance

The main switch of the engine and power supply should be turned off before maintenance.

Check the oil level of hydraulic oil. The hydraulic oil level should be kept above three-fourths of the oil level gauge, otherwise it should be filled with clean hydraulic oil of the same brand. It is recommended to clean the hydraulic oil with a filtration device with a filtration precision of 20μ.

Check the oil quality. After stopping the machine for 30 minutes, use a clean measuring cup to catch 0.5 liters of oil. The oil should be clear and light yellow. If the oil is highly contaminated or appears emulsified or cloudy, or if there is sediment at the bottom after sitting for several hours, the oil should be changed immediately.

The lubricant tank should be filled with grease and the water tank should be filled with fresh water.

Remove the water tank cover and check whether the concrete piston is well sealed and no mortar seeps into the water tank.

Check the gap between the cutting ring and the glass plate. Check the condition of the worn parts after each time the equipment is used and thoroughly cleaned. When the gap between the glass plate and the cutting ring local is greater than 1 mm, the gap should be adjusted. When the gap is greater than 2 mm, the cutting ring should be replaced.

Check the working condition of the lubricating system, whether there is lubricating oil overflowing at the lubrication points such as the bearing position of the S-tube swing arm end and the bearing position of the mixing shaft.

Check the swing of the distribution valve, and whether the forward and reverse rotation of the stirring device can work normally. (This item requires power-on inspection. After the inspection is completed, turn off the equipment and then carry out maintenance work for other items.)

Check that the outside of the cooler is clean. If there is dirt, it should be cleaned immediately, otherwise it will easily cause the oil temperature to overheat.

Check the wear of the concrete pipelines by tapping on them, and check that the line joints are well sealed.

Check the hydraulic system and diesel engine for oil leakage, oil seepage and water leakage.

Check whether the function of each electrical component is normal, check whether all circuit connectors are dry, and whether there is oxidation or looseness. If necessary, spray damp proofing agent on these joints.

Check accumulator. The accumulatorsurface should be kept dry and clean. Oxide and dirt on accumulator and accumulator terminals can cause short circuits, voltage drops and discharges, especially in wet environments. Operators can use a copper wire brush to remove oxide from accumulator terminals and cable splices. Tighten cable splices and coat with protective grease or petroleum jelly.

Maintenance after 50 hours operation(1500-2500m³)

Carry on above maintenance.

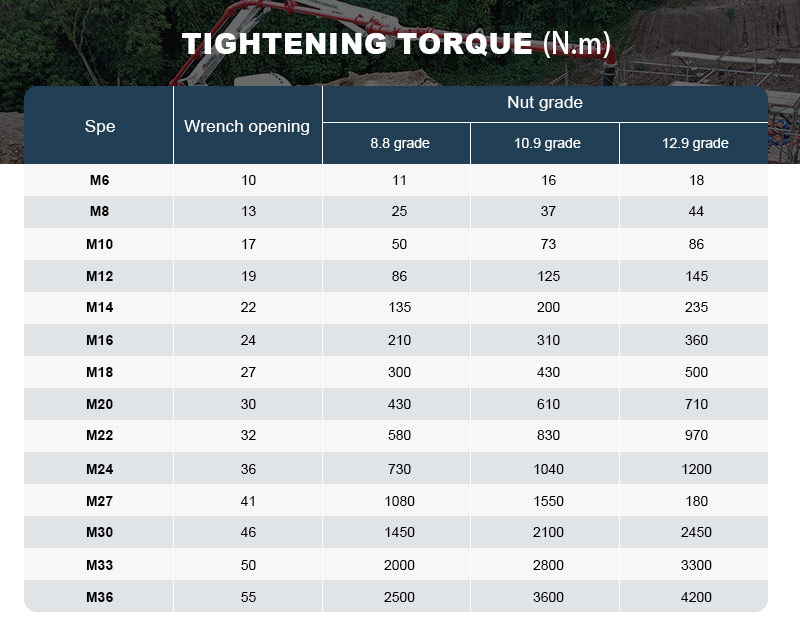

Check whether the bolts of pumping cylinders and drag rods are loose, tighten them with a torque wrench. Tightening torque according to the table below:

Check the bolts of the intermediate connecting rod and others in the water tank to ensure than the connection is firm.

Maintenance after 100 hours operation(3500-5000m³)

Carry on above maintenance.

Check the wear of the cutting ring and glass plate, and replace them in time if necessary.

Check the wear condition of the concrete piston. If necessary, replace them.

Check if the hydraulic fluid is mixed with too much water. Every twenty days, unscrew the base plug at the bottom of the oil tank and drain the water about 2-3L, then fasten the base plug screw.

Check the sealing of grease pump and clean it. If the piston is worn out, replace it if necessary.

Check and clean the filter at the outlet of the lubrication system. Replace in time if damaged.

Check accumulator. The electrolyte should be 5-10mm over the electrode plate of the accumulator. The distilled water is added if necessary. Charge the accumulator after the liquid is filled up by running the engine at the fast idle for at least 30 minutes. Note! Certain free maintenance accumulator has special instructions, which must be followed.

Note:

The accumulator electrolyte contains an extremely corrosive vitriol. Protect your skin and clothes when charging or handling accumulator. Always wear protective glasses and gloves. If accumulator electrolyte spatters on the skin, please flush it immediately with plenty of water and soap. If accumulator electrolyte spatters into n the eyes, please flush them immediately with plenty of water and look for a doctor without delay.

Maintenance after 500 hours operation(15000-25000m³)

Carry on above maintenance.

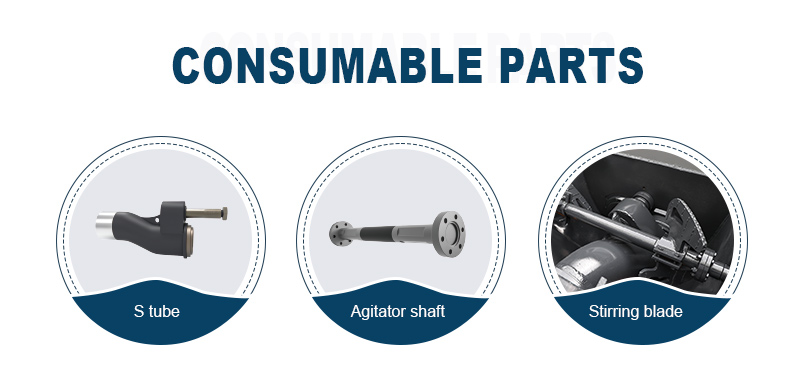

Check the worn condition of S tube and S tube bearing.

Check the worn condition of mixing shaft, mixing blade and mixing bearing.

Check hydraulic oil. If necessary, change it. Only the oil recommended by our company is permitted being filled. Generally, after pumping 10000 m³ concrete, change the hydraulic oil completely.

Check the pressure of the accumulator. The charged pressure of the accumulator is about 10-11MPa.

Maintenance after 750 hours operation

Carry on above maintenance.

Check the wear of the concrete cylinder. Replace it if the chrome plating is worn seriously.

Test the whole machine, every parameter should accord with requirements.

When you choose a reliable concrete pump manufacturer, they will not only provide you with high-quality equipment, but also provide good training and maintenance services. If you have any problems with your concrete pump and need help, please feel free to consult us!