Concrete Mixers

Concrete mixers mainly refer to the equipment that mixes cement, sand, aggregate, and water and mixes it into concrete or a combined device that concentrates on concrete mixing.

Concrete mixing machine includes a stationary concrete batching plant, concrete mixers, self-loading mixers, etc.

Concrete mixing machines are essential equipment in modern construction, ensuring efficient, consistent, and high-quality concrete production. Their role impacts the cost, speed, safety, and structural integrity of buildings and infrastructure.

Choosing a high-quality concrete mixer is key for your concrete production. High-quality concrete mixing equipment helps you produce good concrete, improves construction efficiency, enhances structural durability, enables specialized concrete production, and increases cost-effectiveness.

How can you use Daswell concrete mixer machines for your projects?

As an essential equipment in concrete production projects. Whether for your concrete batching plants or concrete mixer transportation requirements, we can meet your needs. You can use them for your different projects. Daswell offer you various concrete mixing machines for your different projects.

Daswell diesel drum mixers, twin-shaft concrete mixer, and planetary mixing machines are popular for your building and housing construction. The drum type mixer is suitable for small scale construction. If your project is larger, you can choose the twin-shaft and planetary mixing equipment.

- Residential Buildings(Houses, Apartments, Villas)

- Commercial Structures(Offices, Malls, Hotels)

- Foundations, Columns, Beams, and Slabs

We have two types concrete mixer trucks for your roads and highway constructions. The self loading mobile concrete mixer truck is applicable for some remote site. It can mix concrete on-site. If you need large concrete, the transit mixer truck can help you transport the ready-mix concrete from concrete batching plant to working sites.

- Concrete Pavements(Rigid roads, highways)

- Curbs, Sidewalks, and Drainage Systems

- Bridge Foundations and Retaining Walls

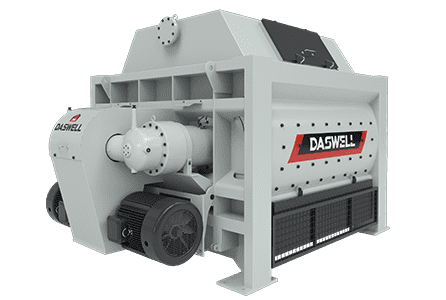

The horizontal twin-shafts concrete mixers is ideal for high-strength concrete production. For your precision mixing requirements, the planetary mixers are more suitable.

- Dams, Bridges, and Tunnels

- Airport Runways and Ports

- Industrial Floors and Warehouses

For some remote areas, where has limited electricity, Daswell diesel drum mixers are available. They eliminate the requirements on electricity, utilizing diesel engine for mixing concrete.

- Farm Roads and Irrigation Canals

- Animal Sheds and Storage Silos

Except for the separate mixing machines, for your large industrial projects, there are concrete batching plants for you.

For your high output requirements, we have large stationary concrete batching plant.

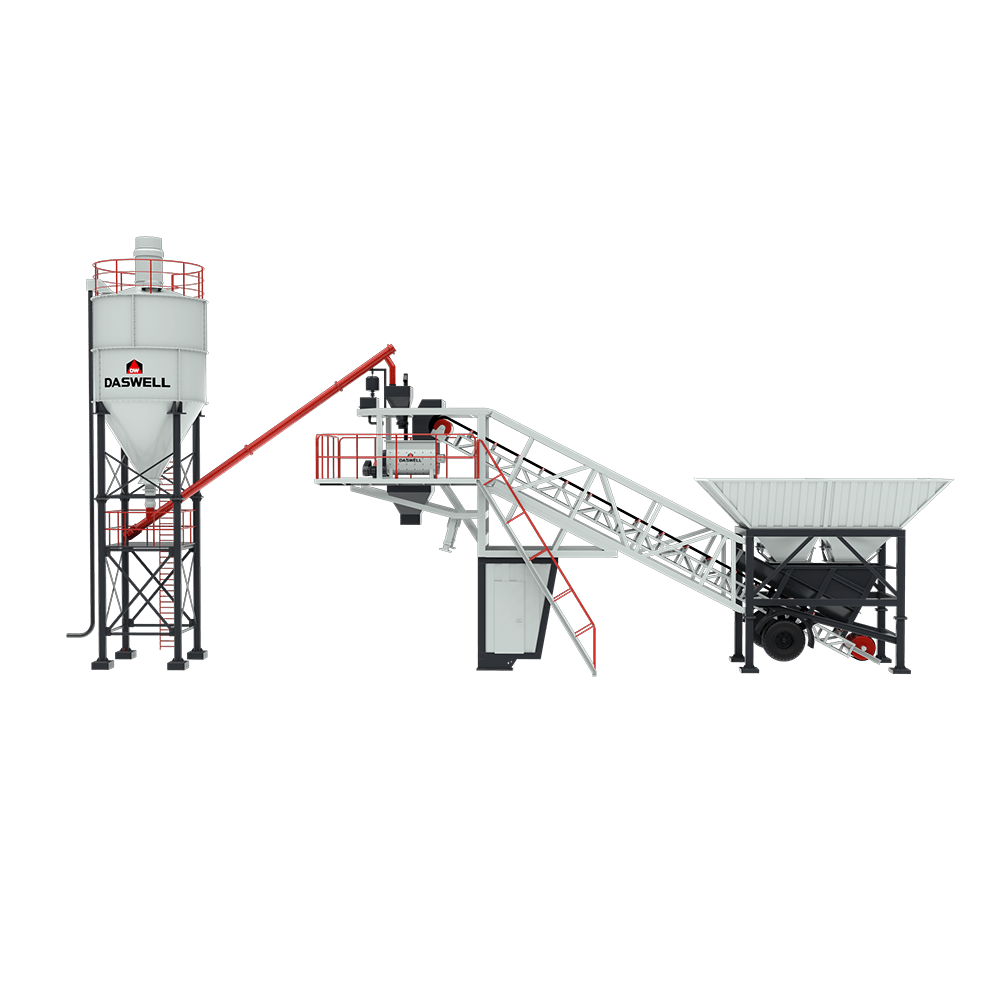

If you should move the plant frequently, the mobile concrete batching plants can meet your needs as well.

Dsawell concrete mixers has wide applications. Selecting a suitable mixing machine for your project can greatly improve your working efficiency. If you do not know how to choose, just send an inquiry to us. Our professional engineers can help you choose the best solution for your specific requirements.

Different types of Daswell concrete mixers

Daswell offers a variety of concrete mixers designed for different applications, from small-scale construction to large industrial projects. Meanwhile, whether for your stationary or mobile, single mixer machine or concrete batching plant, mixing or transporting requirements, Daswell has various concrete mixing solutions for you. Contact Now!

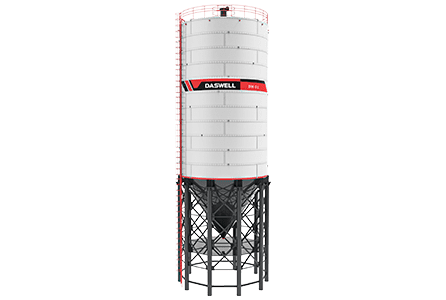

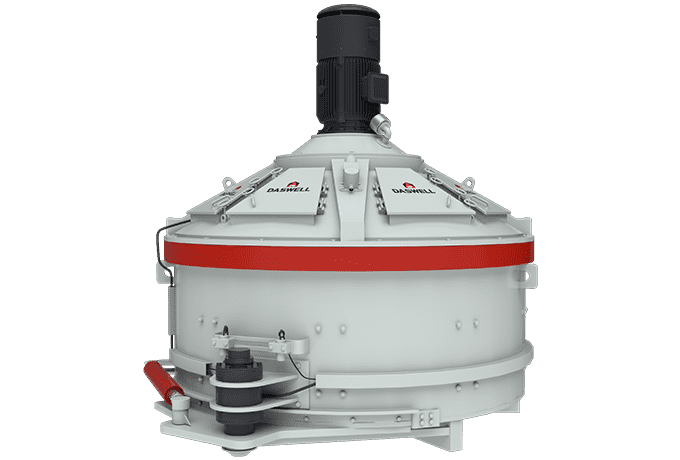

Daswell has some stationary concrete mixers. Generally, the concrete batching plants are equipped with stationary mixers. Their primary function is mixing raw materials for concrete production. We have planetary concrete mixers and twin-shaft horizontal concrete mixers for concrete batching plants.

Generally speaking, the twin-shaft horizontal mixer has a higher mixing speed than the planetary type. But the planetary mixers have better mixing effects. For your information, the vertical planetary concrete automatic mixer machines are more suitable for viscous, adhesive, or decorative mixes. And the horizontal type mixer is often used for handling stiff, fiber-reinforced, and heavy-duty mixes.

These two types mixers are electrical concrete mixers. Daswell also provides diesel drum concrete mixer for you. This kind of mixers has no limit on electric power. If your construction sites has unstable electric power, you can choose our diesel drum mixers.

For your transportation-type concrete mixing equipment requirements, there are self loading concrete mixers and truck-mounted concrete mixing machines for you to choose from. Both of them combine transporting and mixing functions.

It should be mentioned that the main purpose of a concrete mixing truck is preventing concrete from setting. Thus, its primary function is transporting mixed concrete.

The self-loading type can load raw materials automatically and mix the materials when driving. It is ideal for on-site mixing.

Except for these two kinds of concrete mixers with transportation functions. There are also concrete mixer pumps. It combines concrete mixing and pumping functions into one unit, meeting your needs on mixing and pumping simultaneously.

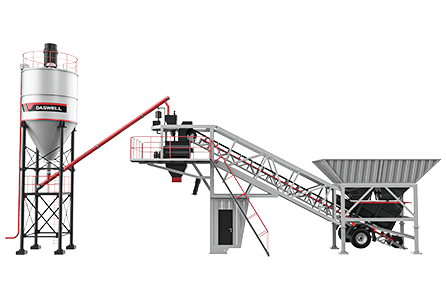

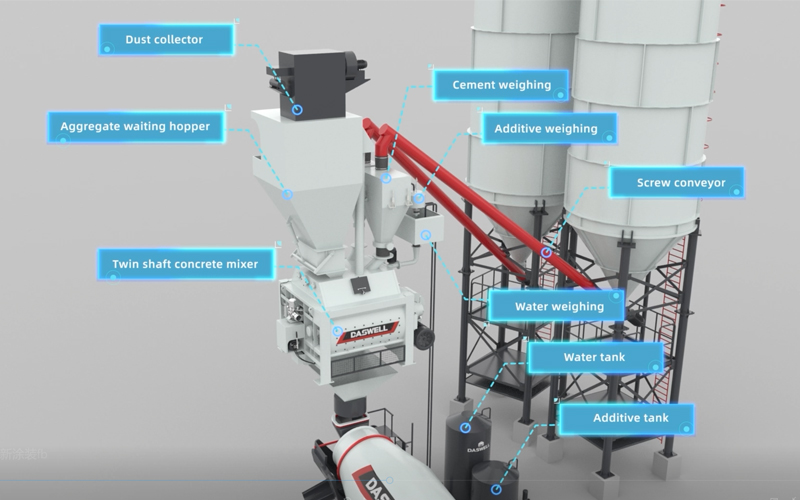

A concrete batching plant is a facility that combines raw materials (cement, water, aggregates, and admixtures) to produce ready-mix concrete efficiently. We have stationary and mobile concrete batching plants for your reference. Both of them are equipped with our stationary concrete mixers for mixing concrete.

The main difference between stationary and mobile-type plants is mobility. A stationary concrete batching plant is more suitable for large-scale projects, and high-volume production (e.g., dams, highways, precast factories) with larger capacity. This concrete batching plant needs fixed installation.

The mobile concrete batching plants are often used for short-term projects, remote sites, and frequent relocation requirements. The mobile plant is compact and trailer-mounted with a shorter installation time.

Advantages of using Daswell concrete mixers for your projects

Concrete mixers offer significant benefits in construction projects. They help improve efficiency, quality, and cost-effectiveness. If you are considering buy a concrete mixing equipment or not, here you can know more about the advantages of the concrete mixing facility.

What are the costs of concrete mixers?

As a professional concrete machine supplier, Daswell can offer you high-quality concrete mixers at good price. Whether for the diesel mixer, electric mixer, stationary mixer, or mobile mixers, we can meet your needs. According to your budget, there are different choices for you.

For your mobile requirements, Daswell self loading mobile concrete mixer and mixer truck are applicable. The self loading type are more expensive than the transit concrete mixer trucks, because of the self loading function and on-site mixing. If you want to buy a mixing machine with mixing and transporting functions with small capacity, this mobile concrete mixer can meet your needs at affordable price. And for you long-distance concrete transporting requirements, the concrete transit mixer truck is an ideal choice for you. And it costs less than the self-loading type.

For your projects in remote area, you may need diesel concrete mixer. Our drum type concrete mixing machine is popular among our customers. Daswell has various drum mixing machines with different capacities. And the larger the discharging volume, the more expensive the machine.

Except for the diesel drum mixer, our electric mixing machine are often used for batching plant. Generally, the vertical planetary concrete mixer costs more than the horizontal twin-shafts concrete mixing equipment. If you need high-grade concrete mixing facility, only planetary mixing equipment can meet your needs. Thus, it has higher price.

For your batching plant needs, Daswell has stationary concrete batching plants and mobile type plants. Generally, the stationary type plant will cost more than the mobile type because it has a higher output capacity. And there are also belt conveyor stationary plants and skip hopper plant. They have different prices as well. For more detailed price, please contact us. Our team can recommend the most suitable solutions with good price for your own projects according to your budget.