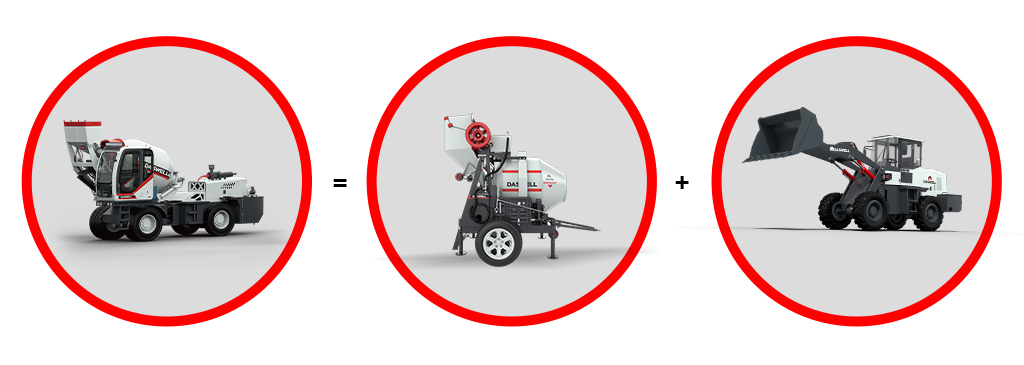

Which Costs Less? — Self Loading Concrete Mixer vs Loader + Mixer

Two common solutions for on-site concrete production

- Option 1: Self loading concrete mixer (one machine can handle loading, mixing, transporting, and discharging)

- Option 2: Wheel loader + diesel drum mixer, where loading and mixing/transport are handled by different machines

Both solutions have their own advantages. But if your priority is saving more cost—not only the purchase price, but also daily operating cost and long-term maintenance—then the best choice depends on the project type, site logistics, labor availability, and how often your jobsite changes.

Want a quick recommendation? Submit your jobsite type, daily output / pour frequency, on-site haul distance, road condition, and crew plan. We’ll reply with a practical suggestion for your situation.

👉 Fill in the Contact Us form to get a recommendation

I. Quick decision guide — self loading Concrete mixer vs loader + Drum mixer

Choose a self loading concrete mixer if you need:

• Fewer operators and less coordination

• Flexibility across multiple jobsites

• A practical “all-in-one” solution for daily work

• Simpler scheduling and lower downtime risk

Choose wheel loader + drum mixer if you need:

• Continuous, high-volume production

• You already have a loader and a stable site organization

• You have enough operators and a predictable schedule

Not sure which fits you? Submit project type + target output + site logistics/haul distance + crew plan. We’ll send back the best-fit option and configuration notes.

👉 Fill in the Contact Us form to get a comparison

II. Core question: what does “saving more” really mean?

Many buyers ask, “Which option is cheaper?” But cost is not only the purchase price. In real projects, savings often come from:

• Labor cost (how many operators and helpers you need)

• Downtime risk (if a key machine fails or manpower is missing, output may drop significantly or even stop)

• Fuel and transport efficiency (haul distance per batch and idle time)

• Maintenance and parts cost (one machine vs two machines)

• Logistics and scheduling (how much coordination you must manage)

So the most suitable and cost-effective solution is not fixed—it should match your actual working pattern.

III. Advantages of self loading mixers and mixers

Option 1: Self loading concrete mixer

A self loading concrete mixer integrates multiple steps into one workflow:

- Load aggregates with the bucket

- Add cement and water

- Mix in the drum

- Drive to the pouring area

- Discharge where needed

Best for:

- Dispersed projects (multiple small pours)

- Remote or frequently moving jobsites

- Labor shortages or high labor cost

- You want simpler scheduling and fewer machines

Option 2: Loader +diesel drum mixer

Typical workflow:

- The loader handles aggregate loading/feeding (depending on site organization, into a hopper, feeding system, or loading area)

- Keep mixing during transport (and if needed, mix briefly before/after arrival to maintain workability)

- Discharge at the pouring location

Best for:

- Continuous, high-volume production

- Stable, well-organized sites with enough space

- You already have a loader and experienced operators

- Projects large enough to support more complex coordination

IV. Cost breakdown: self loading Concrete mixer vs Loader + diesel drum mixer

A. Labor and coordination

- Self loading mixer: usually requires only one main operator.

- Loader + drum mixer: usually requires two operators, plus helpers for material management.

Even if wages are not high, “hidden cost” often comes from coordination. If one operator is absent, one machine fails, or the loader is used elsewhere, output can drop quickly.

If your team is small or you change jobsites often, Option 1 often saves more because it reduces dependence on people and multiple machines.

B. Downtime and scheduling risk

With two machines, you have more possible delays:

- Loader maintenance issues

- Mixer truck issues

- Waiting for the other machine to be available

- Extra time to organize stockpiles and the loading area

A self loading mixer is simpler: fewer parts to schedule.

If pour delays cause financial loss, simplicity has real value.

C. Fuel, idling, and on-site transport

Fuel cost is not only “liters per hour.” It also includes:

- Idle time while waiting

- On-site haul distance

- Trips per day

In Option 2, the loader may idle when the truck is moving, and the truck may idle during loading/waiting. In Option 1, the workflow can be smoother—especially when haul distances are short and pours are frequent.

If your typical haul distance is short, pours are frequent, and you want to reduce waiting/idling, Option 1 often saves fuel in real operation (and usually saves working hours as well).

D. Maintenance and parts

Two machines usually mean:

- More maintenance points

- More wear parts

- More potential downtime

- More spare parts to stock

Option 1 has only one machine, so the maintenance plan is simpler. However, you should still consider machine quality level, hydraulic components, and parts availability from the supplier.

In many contractors’ real situations, one reliable multi-function machine is easier to maintain than coordinating two machines.

If you share your working conditions, we can provide a simple comparison (labor / idle time / downtime / maintenance / scheduling) to show where you can actually save.

👉 Fill in the Contact Us form to get a cost comparison

V. Practical scenarios: self loading mixer vs Loader + diesel drum mixer

Scenario 1: Remote and mobile sites (rural roads, villages, multiple small jobs)

Examples: small slabs, sidewalks, drainage, repairs, farm projects, villa foundations

Pain point: ready-mix transport is costly/unreliable and sites change frequently

Which costs less?

Usually a self loading concrete mixer.

Reason: fewer machines, easier relocation between sites, and simpler labor coordination. For this type of work, the biggest cost is often not capacity—but time and management.

Scenario 2: Stable site, stable output (continuous pouring)

Examples: structural infrastructure projects, large sites with stable working zones

Pain point: continuous supply and higher sustained output

Which costs less?

Often the wheel loader + diesel drum mixer combination is more competitive.

Reason: if you already own a loader, the site is well organized, and you keep both machines running while minimizing downtime, multi-machine coordination can improve efficiency.

That said, when labor is limited, many contractors still use self-loading mixers on stable sites—especially when they value ease of operation more than theoretical maximum output.

Scenario 3: Small team, tight deadlines, unpredictable scheduling

Examples: local contractors with 3–6 workers

Pain point: unstable labor supply; cannot afford delays caused by machine coordination

Which costs less?

Usually a self loading concrete mixer, because it reduces dependence on multiple operators and machines. This is a management advantage.

VI. Comparing quotations: self loading Concrete mixer vs loader & drum mixer

If you compare these two solutions, ask suppliers the following:

- How is rated capacity defined?

Drum volume is not always equal to “output per batch.” - Which drive type is included (2WD / 4WD)?

Road conditions matter. If the site is muddy or on slopes, drive type affects productivity. - What is included in the standard package?

Chutes, tools, manuals, basic spare parts, and operator training should be clearly stated. - What are the brands of key components?

Engine, hydraulic system, and electrical parts often explain price differences. - After-sales support and spare parts availability

Discuss remote guidance, spare kit options, and response time early. - Packing plan and delivery time

Container loading plan, delivery schedule, and what you need to prepare at destination.

A good supplier will provide clear answers and confirm them in writing to avoid “surprises” after delivery.

Want a quote-checklist to compare suppliers on the same basis? We can share a checklist (capacity definition / standard scope / key brands / spare kit / packing & lead time).

👉 Fill in the Contact Us form to get the checklist + quote guidance

FAQ

-

Can it replace both a loader and a Drum mixer?

For many small and mid-size projects, yes—because it integrates loading and mixing/transport into one workflow.

-

Is a self loading concrete mixer suitable for remote areas?

Yes. Remote and mobile sites are among the most common reasons buyers choose self loading concrete mixers.

-

Does “saving more” mean buying the cheapest machine?

Not necessarily. Savings often come from lower labor demand, reduced downtime, and simpler daily operation.