7 Tips to Help You Choose a Better Concrete Mixer Pump for Your Project

Are you planning to buy a concrete mixer pump? If yes, please read on. This article shares practical tips to help you select the right machine for your jobsite.

A concrete mixer pump can mix and pump concrete at the same time. This saves time, reduces labor, and improves pouring efficiency. Compared with buying a mixer and a concrete pump separately, a concrete mixer with pump is often a more practical choice for many small and medium projects.

However, there are many brands and models of concrete mixer pump machines on the market. Quality and performance can vary a lot. So how can you choose a reliable, efficient, and cost-effective concrete mixer pump for sale? Here are 7 useful tips.

1. Types of Concrete Mixer Pumps

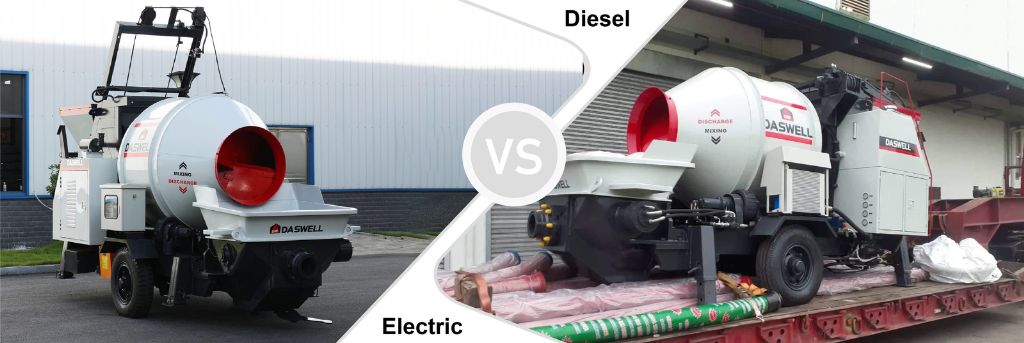

Start by choosing diesel or electric. Most concrete mixer pumps are diesel-powered or electric-powered. Each type fits different sites and budgets.

1) Diesel Mixer Pump

A diesel concrete mixer pump is a good option for remote areas or job sites without stable electricity. It can work independently and has strong adaptability.

A diesel concrete mixer with pump is ideal for:

- Remote construction where power supply is not stable

- Projects that need frequent relocation

- Sites that require long continuous operation

Diesel models are flexible, but the running cost depends on fuel consumption. When comparing any concrete mixer pump for sale, always check the engine brand, power, and fuel efficiency.

2) Electric Mixer Pump

An electric concrete mixer pump is driven by an electric motor. If your site has stable three-phase power, electric models are usually more economical over time.

An electric concrete mixer with pump is suitable for:

- Job sites with stable electricity

- Urban projects with lower noise requirements

- Users who want lower long-term operating cost

If your site has stable power supply, an electric concrete mixer pump can be the better value.

Quick Comparison Table (Diesel vs Electric)

| Type | Best for | Key advantage | What to check before buying |

| Diesel concrete mixer pump | Remote areas, mobile projects | Strong flexibility, independent power | Fuel use, engine quality, maintenance access |

| Electric concrete mixer pump | Stable power sites, urban projects | Lower running cost, lower noise | Voltage, motor power, cable safety |

DASWELL provides a full range of concrete mixer pump models to meet different job site needs.

2. Actual Continuous Pumping Distance

Real pumping distance matters more than “max distance.” When buying a concrete mixer pump, you must confirm the actual continuous pumping distance on a real construction site.

Theoretical pumping distance ≠ real pumping distance.

Many suppliers list “maximum pumping distance,” but this is often tested under ideal conditions, such as straight pipelines and high-flow materials. In real projects, a concrete pump system faces many limits, so the distance usually drops.

Key factors that reduce pumping distance:

- Pipe length and number of bends

- Concrete slump and mix design

- Site layout and elevation changes

- Temperature, weather, and long working hours

So the reliable standard is not the “maximum number.” The real standard is whether the concrete mixer pump can pump smoothly and continuously without pressure loss, frequent blockage, or interruptions.

DASWELL concrete mixer pump performance data comes from jobsite testing. This helps customers choose a concrete mixer pump for sale with more stable real performance and fewer risks of downtime.

3. Hydraulic System Brand

A strong hydraulic system keeps pumping stable. The hydraulic system is the core of a concrete mixer pump. It affects pressure, speed, and temperature control.

If the hydraulic system is not reliable, you may face:

- Pressure fluctuations

- Overheating

- Slow pumping speed

- Frequent malfunctions

These problems lead to downtime and higher maintenance costs.

DASWELL Advantage: DASWELL uses well-known hydraulic components from brands such as Rexroth, Kawasaki, and Weichai. This helps the concrete mixer with pump run more smoothly and work longer with fewer interruptions.

4. Adaptability to Different Concrete Mix Ratios

Concrete changes every day on site. Slump and aggregates are not always the same. Sometimes concrete is wet and fluid. Sometimes it is dry and stiff. Stone size may also change.

If a concrete mixer pump has poor adaptability, it may cause:

- Uneven mixing

- Weak pumping flow

- Pipe blockage

Blockage often forces the team to stop and clean the pipeline. This delays progress and adds cost.

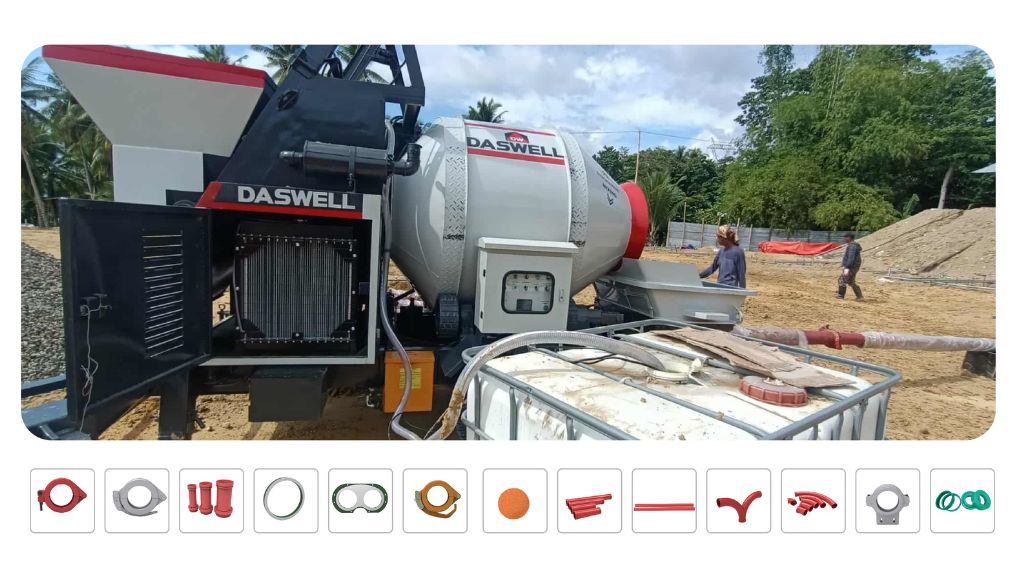

DASWELL Advantage: DASWELL concrete mixer pumps are designed for complex working conditions. The machine uses a powerful mixing system, a large-capacity mixing tank, and a large-capacity conveying cylinder. It also has a large-diameter discharge port and heavy-duty mixing blades. These features improve mixing and reduce blockage risk, keeping the concrete pump system more stable.

5. Safety Features and Operating Comfort

Safety and easy operation improve efficiency. A concrete mixer pump works with high pressure and continuous output. If safety protection is weak, failures and risks can increase. Also, operator fatigue can reduce efficiency and raise accident risk.

When choosing a concrete mixer pump for sale, check these features:

- Emergency stop button (easy to reach)

- Overload protection and safety system

- Clear pressure and temperature gauges

- Remote control option for safer operation

DASWELL concrete mixer pumps focus on user-friendly design. The control panel is clear, and some models support wireless remote control. This allows the operator to control the concrete mixer with pump from a safer distance while watching concrete flow in real time.

6. After-Sales Service and Spare Parts

Fast support reduces downtime. Even a high-quality concrete mixer pump may need maintenance after long-term use. If spare parts are not available, a small problem can stop the project for days.

Before purchasing a concrete mixer pump, confirm:

- Spare parts stock and shipping speed

- Remote video support or on-site service

- Response time for troubleshooting

DASWELL provides after-sales support and spare parts supply with sufficient inventory and fast response. Operation videos and maintenance manuals are also available, helping customers fix common issues faster and keep the concrete pump system running.

7. Wear Parts and Long-Term Costs

Wear parts decide long-term cost. The purchase price is only one part of the cost. The total cost also includes wear parts replacement and downtime loss.

Common wear parts include S-valves, cutting rings, and spectacle plates. They contact concrete directly, so they wear faster. Low-quality wear parts mean:

- Frequent replacement

- More maintenance cost

- More downtime

In the long run, “cheap equipment” can become more expensive.

DASWELL concrete mixer pumps use high-strength wear-resistant materials and durable wear parts. This reduces replacement frequency and helps users lower the total cost over the full service life of the concrete mixer pump.

Quick Selection Checklist (Before You Buy)

If you are comparing a concrete mixer pump for sale, this checklist helps you decide faster:

- ✅ Diesel or electric concrete mixer pump based on your power supply

- ✅ Verified continuous pumping distance (real jobsite data)

- ✅ Reliable hydraulic system brand and structure

- ✅ Suitable max aggregate size for your local materials

- ✅ Safety protection + clear gauges + easy operation

- ✅ Spare parts supply and after-sales response speed

- ✅ Wear parts quality (S valve, cutting ring, spectacle plate)

Conclusion&Contact Us

Choosing the right concrete mixer pump is not only about price. You should also focus on real pumping distance, hydraulic reliability, adaptability to concrete mixes, safety design, spare parts support, and wear parts cost.

With stable performance, durable components, and fast service support, DASWELL helps customers reduce downtime, lower costs, and improve construction efficiency with each concrete mixer with pump.

If you are looking for a concrete mixer pump for sale, contact DASWELL today for a free quote and the latest catalog. We will help you select a reliable machine with strong concrete pump performance for your project.