Two DASWELL WDR260 Water Well Drilling Rigs Delivered to Manila, Philippines

Project Background

In early 2025, a construction and agricultural water supply contractor from Manila, Philippines contacted us regarding their need for reliable deep water well drilling equipment. Their upcoming projects required drilling multiple wells between 260 and 350 meters, which demanded a powerful, stable, and fuel-efficient water well drilling rig.

The customer previously used an older rig with limited depth capacity and frequent failures, which caused severe delays. Their priority was to find a high-efficiency borehole drilling rig for sale that could operate continuously under Manila’s mixed soil layers—soft soil, gravel, and occasional hard rock.

After comparing several manufacturers, the customer selected two units of WDR260 water well drilling rigs.

Project Challenges

The Manila project came with several important challenges that required a reliable and carefully planned drilling solution. First, the water wells needed to reach depths of 260–350 meters, which is beyond the capability of many compact drilling rigs commonly available in the market. This meant the customer needed equipment with stronger power, higher drilling efficiency, and stable performance at greater depths.

In addition to the depth requirements, the geological conditions in Manila added further complexity. The site features alternating layers of clay, gravel, dense sand, and weathered rock, which demand high torque output and dependable down-the-hole hammer performance to maintain consistent drilling speed and avoid interruptions.

The project also had a tight construction schedule. The customer required the drilling rigs to be delivered, installed, and put into operation within a very short timeframe, making production coordination and after-delivery support critical to the project’s success.

Finally, exporting heavy drilling equipment to Manila presented logistical challenges. Water well drilling rigs are long, heavy, and accompanied by numerous accessories such as drill rods, drill bits, and auxiliary equipment. This required careful planning to ensure a safe, efficient, and cost-optimized shipping solution.

To address all these challenges, we provided a complete, end-to-end solution, covering equipment selection, configuration optimization, logistics arrangements, and technical support to ensure smooth delivery and rapid deployment.

How the Customer Found Us

The customer discovered us through a Facebook Ads, using keywords such as:

- water well drilling rig for sale

- deep water drilling machine

- borehole drilling equipment Philippines

Our website ranked well, with detailed product descriptions, videos, and real global cases. After browsing several WDR model pages, the customer initiated a WhatsApp consultation with our sales engineer.

Within 10 minutes, the customer received drilling parameters, soil adaptability analysis, and a customized quotation. This professional response convinced them to request a video call and a factory inspection.

Why the Customer Chose DASWELL

The customer ultimately selected DASWELL over other suppliers for several reasons:

① Strong Drilling Capacity

WDR260 can easily drill 260–350 meters using both mud pumping and air compressor systems.

Our high-torque rotary head and reinforced chassis outperform common low-cost rigs.

② Proven Performance in the Philippines

We have successful cases in Cebu, Davao, Isabela, Cagayan, and Manila, with machines running over 3 years with minimal breakdown.

③ Complete After-Sales Support

We provide:

24/7 online service

Local parts supply

Remote troubleshooting

On-site commissioning support

Competitors often lack long-term spare parts availability.

④ Full Accessory Compatibility

Unlike other brands that sell rigs without necessary tools, DASWELL offers a complete drilling package including different-size drill bits, drill rods, and mud pumps.

⑤ Honest Pricing & Low Maintenance Cost

Our rigs offer 20–30% lower fuel consumption, reducing long-term operational cost.

The customer concluded that DASWELL provided the best performance-to-price ratio in the market.

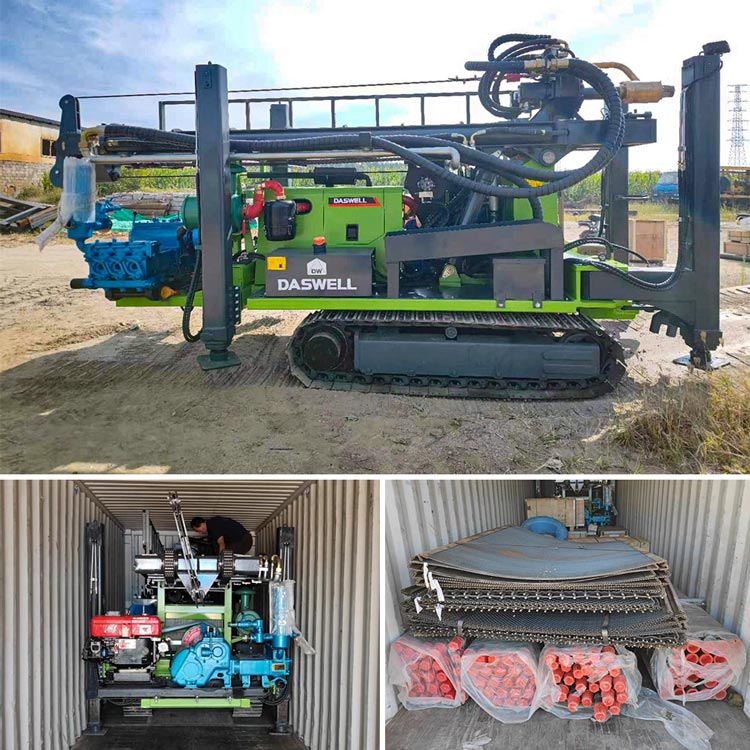

Optimized Shipping & Container-Loading Plan

The two WDR260 drilling rigs come with many accessories, so container optimization was critical to reduce shipping cost while ensuring safety.

Container Solution

1 × 40HQ container

Reinforced Loading Measures

a.Frame points double-secured

b.Tire locks and chains fixed at the chassis

c.Wooden blocks under support legs

d.Wrapping protection on all hydraulic components

Container Loading List

a. 2 × WDR260 water well drilling rigs

b. Drill rods (60 pieces)

c. 4-inch drill bit

d. 6-inch drill bit

e. 8-inch drill bit

f. 10-inch drill bit

g. 12-inch drill bit

h. Mud pump assembly

i. High-pressure hose kits

j. Air compressor pipelines

k. Toolboxes & spare parts

We provided detailed loading photos and videos to the customer for confirmation.

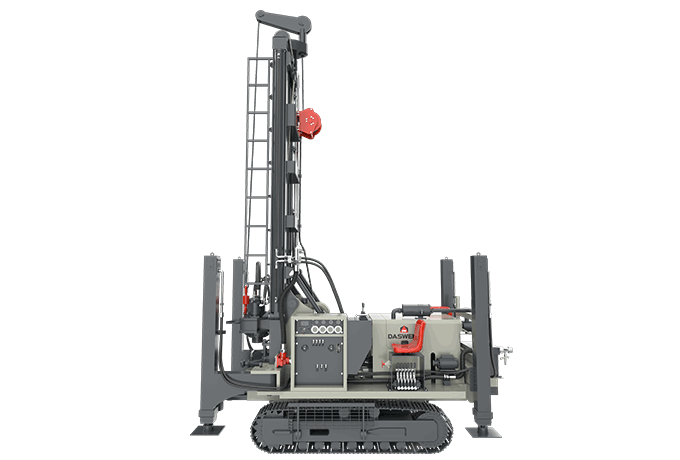

WDR260 Water Well Drilling Rig Configuration

Main Specifications

a. Drilling depth: 260–350 meters

b. Drilling diameter: Φ110–330mm

c. Engine: Turbocharged diesel engine

d. Rotary head torque: High-strength heavy-duty type

e. Lifting force: Strong hoisting winch

f. Hydraulic system: Large-flow system

g. Walking mode: Crawler chassis

Included Accessories

a. 4, 6, 8, 10, 12-inch drill bits

b. Drill rod sets

c. Mud pump

d. DTH hammer compatibility

e. Tool set & spare parts package

f. Maintenance kit

A complete package allowed the customer to begin drilling immediately after setup.

Installation, Commissioning & Training

After the drilling rigs arrived in Manila, DASWELL engineers supported the customer through:

✔ Online installation guidance

Video sessions covering hydraulic system connection, mast erection, and safety checks.

✔ On-site commissioning (via local partner)

Testing rotary head, mud pump flow, air system pressure, and crawler movement.

✔ Operator Training

We trained their team on: Proper drilling workflow、drill bit replacement、mud mixing & circulation、daily maintenance & lubrication、safety precautions、the rigs were officially put into operation within 48 hours.

Project Results & Customer Benefits

After two months of use, the customer reported excellent performance. The two WDR260 rigs enabled them to drill wells much faster, completing each 300-meter well in significantly less time and reducing operational costs. Fuel consumption was lower than their previous machine, and the rigs performed reliably even in challenging soil layers. With fewer breakdowns and higher drilling accuracy, the customer maintained project schedules and improved client satisfaction. Overall, the DASWELL WDR260 rigs allowed them to expand business capacity, take on more projects, and increase profitability.

Customer Feedback

“The DASWELL WDR260 is powerful, stable, and fuel-efficient. Drilling 300 meters is no problem at all. Your support team helped us start working very fast. We will definitely buy more rigs for future projects.”

— Contractor, Manila, Philippines

Conclusion

This project once again proves that DASWELL water well drilling rigs deliver exceptional performance for deep well drilling projects in the Philippines.

With strong drilling power, reliable components, competitive price, and comprehensive support, DASWELL continues to be a trusted supplier of water well drilling equipment for global customers.

Product Related