What are the two major problems in concrete pumping works?

Concrete pumping is a crucial process in modern construction. Using a concrete pump machine, you can realize highly efficient placement of concrete in hard-to-reach areas. However, there are some challenges of pumping. It may affect the project timelines and quality. Here you can learn two major problems in concrete pumping works: blockages and pipeline wear. And we also provide practical solutions for mitigating these problems.

By knowing these issues and implementing best practices, you can enhance efficiency, reduce downtime, and ensure smoother operations.

Blockages in concrete pumping: causes and prevention

When the concrete stops flowing smoothly through the pipeline, the blockages may occur. It is also called concrete pumping plug. This can result from improper mix designs, segregation, or pipeline issues. When the blockages happen, work will halt. And the whole project will be delayed. The labor costs will be higher as well.

Generally, the common causes include stiff mixes, excessive aggregate size, and poor lubrication. It is key for you to identify these factors early. It will be helpful for preventing costly disruptions.

How can you prevent the blockages during the concrete pumping?

For minimizing the blockages, you had better ensure the concrete mix has optimal slump and workability. It is applicable for you to use some admixtures to improve the flowability without segregation.

Meanwhile, lubricating the pipelines properly before pumping and keeping a steady pumping speed are also helpful. Besides, you can inspect the hoses and bends, where blockages often occur regularly.

Training your operators to recognize the signs of blockages early can also prevent major stoppages.

For your referencee, cleaning the concrete pump machines and pipelines after pumping is also essential for avoiding the blockages.

Pipeline wear and tear: causes and mitigation

Because of the high-velocity flow of abrasive materials, the concrete pumping pipelines may endure significant abrasion. This may lead to thinning walls, leaks, and eventual failure. And the bends and joints will wear out faster. It may increase the maintenance costs.

Moreover, the high-pressure pumping, aggregate hardness, and poor pipeline alignment also accelerate wear. Noticing these factors will be helpful for selecting durable materials and maintenance strategies.

How to prolong the pipeline lifespan?

To reduce the degradation, you can choose high-quality, wear-resistant steel pipes. It is also applicable for rotating the pipes periodically. This can distribute wear evenly. Additionally, minimizing the sharp bends and optimizing pipeline layout decreases stress points.

You can inspect regularly and replace worn sections before failure. It ensures uninterrupted operations. You can invest in durable pipelines even though they may have higher upfront costs. For long-term projects, it saves your money.

Benefits of proper maintenance for concrete pump machines

Decreases breakdowns and safety hazards. It is essential for you to maintain the concrete pumping machines well for efficient pumping. If you neglect the maintenance, it may lead to breakdowns, blockages, and safety hazards. Checking the pumps, pipelines, and valves regularly can prevent unexpected failures.

Saves your money. You had better inspect the hydraulic systems, seals, and lubrication points daily. Addressing the minor issues early can avoid costly repairs and downtime.

Prolongs the equipment’s lifespan. Cleaning the pipelines after each use, using compatible lubricants, replacing worn parts promptly, and training staff on proper equipment handling can ensure longevity. Except for the regular maintenance, the partner is also important. Partnering with a reliable supplier for genuine spare parts also enhances equipment performance and durability. As a professional concrete pump supplier with rich experience, we can meet your needs and ensure the machine quality with excellent manufacturing and after-sales services.

Daswell concrete pumps optimization for your better pumping projects

Daswell Machinery is a leading manufacturer of construction equipment. We offer high-performance concrete pumps for your different project requirements. Our concrete pumping facilities are designed for reliability and productivity. For your concrete pumping, you can choose Daswell. We have optimized our pumping machine from types, designs, configurations, testing, and services. These help you maximize efficiency, reduce downtime, and achieve superior results in your pumping operations.

Various concrete pump machine choices for your different pumping requirements

Daswell offers a variety of concrete types for your various pumping projects. For your different projects, there are various choices for you.

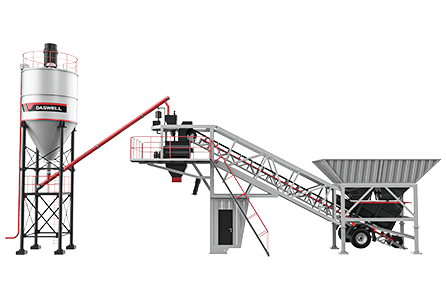

For example, if you need pumping and mixing machines for your remote sites, Daswell concrete mixer pump machines can meet your needs well.

For your high-rise construction pumping, we have boom pump truck, offering extended reach and flexibility.

The trailer type concrete pumping equipment is ideal for small to medium projects with moderate pumping distances.

Choosing suitable pumping machines, it can improve your pumping efficiency at a low cost. And the matched pressure, slump, and mobility also help decrease the downtime, avoiding machine breakdown.

Advanced designs for efficient pumping effects

Robust hydraulic systems: Daswell pumps feature high-pressure hydraulic systems for smooth concrete flow. This minimizes blockages. The advanced designs ensure consistent pressure, even with sense mixes.

Wear-resistant materials: For the critical components like pipeline sleeves, pistons, and cylinders, we choose hardened steel to resist abrasion. These extend equipment lifespan.

Energy efficiency and automation: Modern Daswell pumps incorporate energy-saving technologies and automated controls. These reduce fuel consumption and operator workload.

Our well-designed concrete pumps ensure long-term reliability and cost savings.

Configured machines for concrete mix production

For avoiding the pumping blockages, the concrete mix is also important. High-quality concrete mix can improve the pumping efficiency and decrease blockages. Daswell also provides high-quality concrete mixers for your concrete mix production.

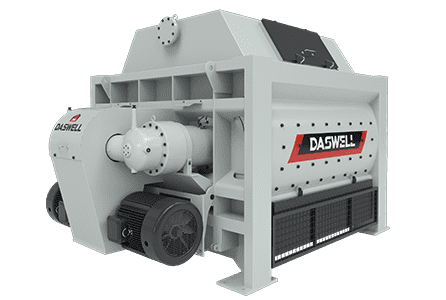

Our twin-shaft horizontal mixers and vertical planetary concrete mixing machines are popular among our customers for concrete production. Both of them can mix concrete materials evenly with high efficiency. Especially, the planetary mixers can produce high-grade concrete mix.

Besides, for your large concrete production and relocation needs, there are also stationary concrete batching plants and portable mobile concrete plants for you to choose.

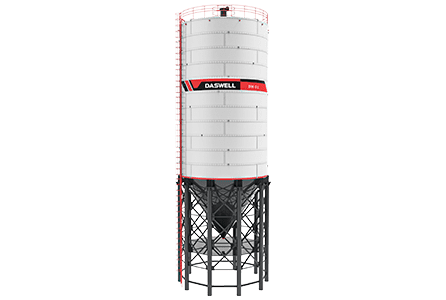

And for storing the cement, we have bolted silos, which can be installed easily.

Professional testing and adjustments before delivering

Before shipment, there will be pre-delivery testing for reliable performance. The pressure tests ensure that pumps handle maximum loads. Leak checks verify hydraulic and pipeline integrity. Performance trails confirm output rates and stability.

Especially, Daswell provides technical assistance during initial setup, ensuring smooth operation from day one. Daswell thorough testing minimizes breakdowns and ensures your project’s readiness.

Online and on-site training and safety measures for pump operators

For making your operation more efficient, smooth, and safer, Daswell provides both online training videos and onsite training. The basic training modules include pump operation and controls, maintenance basics, and troubleshooting blockages. We will help you understand settings for different mixes, daily checks, and lubrication routines, and prevent and resolve common issues. Well-trained operators can reduce accidents, improve efficiency, and extend equipment life.

Choosing Daswell concrete pumps for pumping projects, you can maximize success! With Daswell professional services, you can improve the productivity, reduce downtime, and achieve superior concrete placement results. Daswell Machinery continues to innovate, offering cutting-edge solutions for all concrete pumping challenges. Invest in the right equipment and expertise for smoother, more efficient construction projects. Just contact Daswell now!