Mobile Asphalt Mixing Plant in Philippines

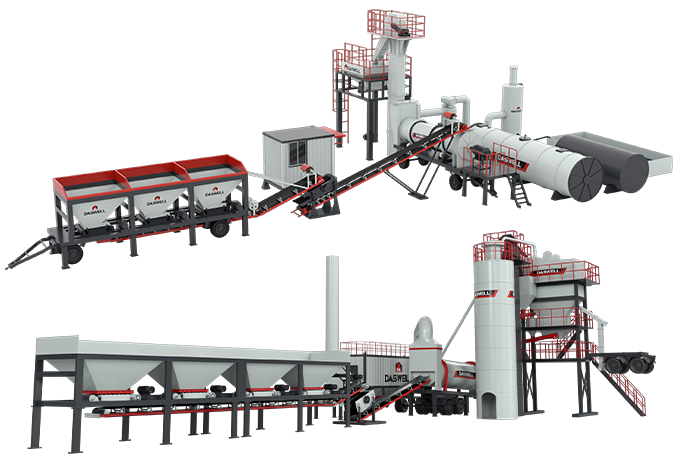

Mobile asphalt mixing plant is a kind of equipment that mixes stone, asphalt and mineral powder according to a certain proportion to produce asphalt mixture. Compared with the fixed asphalt station, the unique walking system makes the transition more convenient for your Philippine projects.

Contact our local Philippines team at +63 915 802 0960 for personalized assistance and a fast quote!

Daswell mobile asphalt plants for sale in Philippines have unmatched flexibility and efficiency. They are ideal choices for short-term or relocating projects in Philippines. This type of asphalt plants is mounted on sturdy chassis. It enables quick setup downtime between job sites.

There are two types of mobile asphalt mixing plants in Daswell for you to choose. The drum type mixing plant can mix asphalt continuously. It is suitable for high capacity requirements. The mobile type batching mix asphalt plant is more suitable for your Philippine projects, which have strict requirements on the asphalt quality. The batch mix plant can realize precise control. It performs better than the drum mix plant. Our mobile asphalt mixing plants are catering to diverse needs like highway repairs, rural road construction, and urban maintenance in Philippines.

Especially, our Philippine mobile asphalt mixing plant has various fuel options for you, including diesel, natural gas, or coal. Meanwhile, it is available for you to choose eco-friendly dust collectors. Daswell mobile asphalt plants balance productivity, portability, and environmental compliance for Philippine contractors handling dynamic projects.

Drum vs. Batch: Choosing the Right Mobile Asphalt Plant for Maximum Efficiency

The mobile asphalt is mainly designed for projects, which require flexibility. We have drum type and forced type for mixing the asphalt. The main difference between these two types of mobile asphalt plants are mixing machines. Each of them has unique advantages for different construction needs. Here are some features of these two types of plants for you to choose the suitable mixing plant for your asphalt road projects in Philippines.

Mobile asphalt drum mix plant: compact and cost-effective

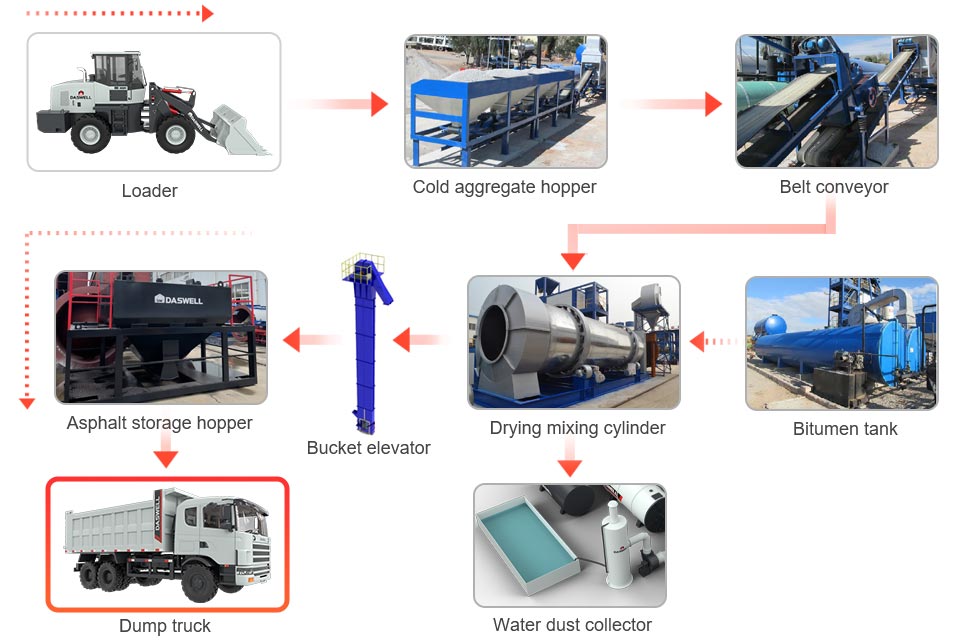

The drum type mobile asphalt plant is perfect for small to medium projects like rural roads or low-traffic pavements. It combines efficiency with portability. Its streamlined workflow starts with cold aggregates being loaded, screened, and dried in a rotating drum while mixing with hot asphalt. Especially, the integrated dust collector ensures eco-friendly operation. This makes it ideal for temporary job sites.

Its key benefits include easy relocation, small footprint, and lower upfront cost than the batch plant. It can be mounted on a trailer chassis for you to move it easily. The small footprint makes it applicable for tight workspaces.

Mobile asphalt forced mix plant: precision for demanding projects

For your high-standard applications such as expressways and airport runways in Philippines, the forced mix plant delivers superior-quality asphalt. Different from the drum mix plant, it utilizes a twin-shaft mixer machine to ensure thorough blending of materials. This forced mixing process involves precise weighting of aggregates, mineral powder, and asphalt before forced mixing, guaranteeing consistency.

It is featured with higher automation, stricter quality control, and modular mobility. This plant employs PLC system for controlling the batching precisely. And the strict quality control makes it more suitable for premium pavements.

In a word, if you need temporary production or frequent relocation, the mobile drum type mix plant is applicable. And if you have high requirements on the mixing quality, the mobile forced mix plant is your best choice.

Want to boost your paving efficiency? Let’s match you with the perfect mobile asphalt plant! Contact us today for a customized quote!

How to get high quality mobile asphalt mixing plant in Philippines?

Looking for a high-quality, reliable mobile asphalt mixing plant in Philippines? Here is a guideline for you to choose an experienced asphalt machinery supplier with high quality machines in Philippines.

Choose the right type of mobile asphalt plant

Generally, there are two main types of mobile asphalt mix plants for your different projects.

- The drum type mobile asphalt plant is best for small to medium projects, such as rural roads, patch repairs with fast production and easy mobility.

- The batch mix mobile plants are ideal for highway and airport construction. They can offer precise mix quality and better control over materials.

Select a trusted supplier like Daswell

Daswell mobile asphalt plants have been exported worldwide, including Philippines, Indonesia, Egypt, and so on. Especially, we have a branch in Philippines. Many Philippine customers give us positive feedback. Choosing Daswell in Philippines, you can get high efficiency and durability. Meanwhile, it can be sure that we provide you the cost-effective solutions with high quality. Especially, whether for the installation, training, or spare parts available, we offer you full after-sales support.

Get a customized quote

Please contact us with your required capacity, preferred fuel type, dust control needs, and project location and timeline. We will provide a tailored solution and best price for your needs in Philippines.

Fast delivery and installation

Daswell has large stocks of mobile asphalt plants in Philippines for fast delivery. And we can also assist with on-site assembly and testing, operator training, and maintenance guidance.

Besides, if you need higher capacity, there are also stationary asphalt mixing plant for you to choose in Philippines.

If you need, just contact Daswell in Philippines for more detailed information and price!

The Ultimate Site Selection Checklist for Mobile Asphalt Plants in Philippines

It is crucial for you to selecting a right location for your mobile asphalt plant in Philippines. It may affect the efficiency, cost control, and environmental compliance. How to choose the best site for your mobile asphalt plants in Philippines? Here are key factors to consider when setting up your plant.

Proximity to construction site

The optimal transport distance should be under 80km. This is ideal for maintaining asphalt temperature and quality. The maximum distance should be within 100km. Beyond this, the asphalt mixture may cool. This will affect the paving performance.

Raw material accessibility

During the production, mobile asphalt plant requires lots of sand, gravel, and slag. You had better choose a place, which is near the quarries or suppliers to minimize transport costs.

Geological and terrain conditions

It is key to avoid flood-prone areas. Or, the water logging will damage equipment. The flat and well-drained land will be suitable. Besides, the compact soil is helpful for stable foundation setup. Thus, you should avoid unstable ground, such as landslides, sandy soil, or fractures.

Environmental and community impact

The noise and dust control should be considered as well. You had better set the plant 500m+ away from schools, hospitals and residential areas to minimize complaints. And checking permitting requirements for air and noise pollution, use baghouse filters to reduce dust emissions.

If you need professional site planning advice and plant recommendations, contact us for mobile asphalt solutions!

Technical Data:

Mobile asphalt drum mix plant

| Model | Capacity(t/h) | Weighing Accuracy(%) | Total Power(kw) | Fuel Consumption(kg/t) | ||

| Aggregate | Asphalt | Coal | Oil | |||

| MADP-40 | 40 | ±1.5% | ±1% | 75 | 10~13 | 5.5~7 |

| MADP-60 | 60 | ±1.5% | ±1% | 128 | 10~13 | 5.5~7 |

| MADP-80 | 80 | ±1.5% | ±1% | 165 | 10~13 | 5.5~7 |

| MADP-100 | 100 | ±1.5% | ±1% | 200 | 10~13 | 5.5~7 |