Asphalt Drum Mix Plant in Philippines

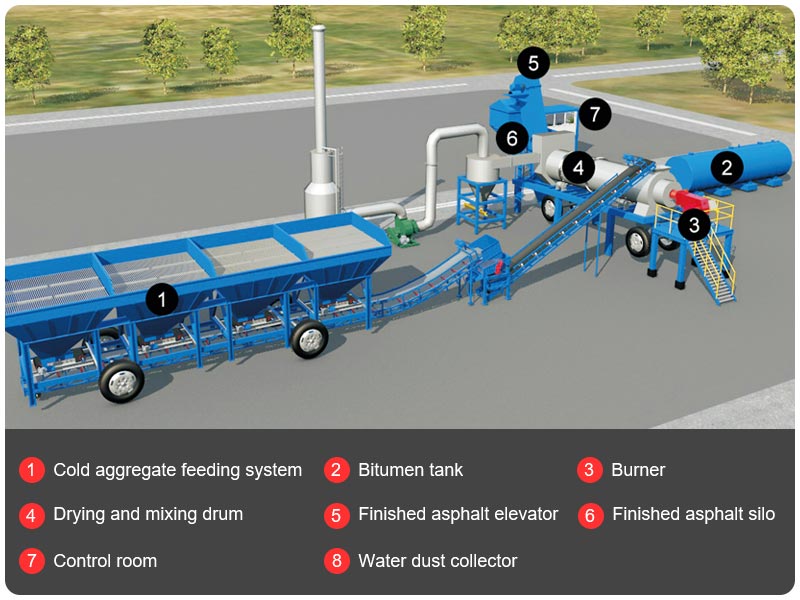

The asphalt drum mix plant is a kind of heating and mixing equipment for block asphalt mixtures, which is mainly used for the construction of rural roads, low-grade highways and so on.

Its drying drum has functions of drying and mixing. And its output is 40-100tph, fitting for small and medium-sized road construction projects in Philippines. It has the features of integrated structure, less land occupation, convenient transportation and mobilization.

Contact our local Philippines team at +63 915 802 0960 for personalized assistance and a fast quote!

Daswell asphalt drum mix plants are commonly known as continuous mixing asphalt plants. They can produce hot mix asphalt non-stop. It is different with the batch mix plants. The drum type asphalt mix plants are ideal for your Philippine road construction projects, which require steady output without frequent stops.

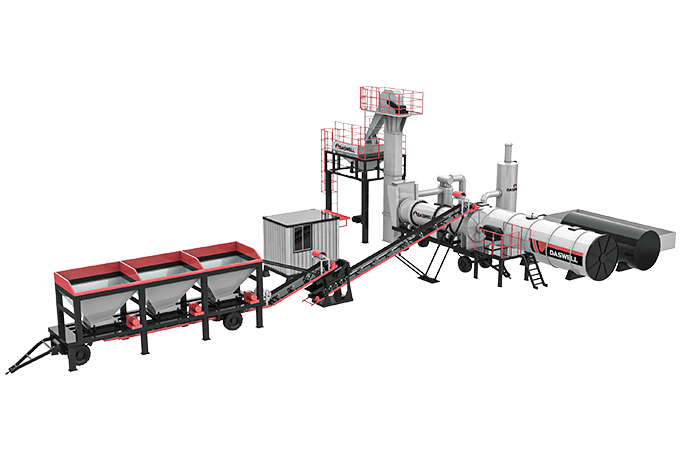

There are two main types: stationary and mobile. Based on our years of experience in Philippine market, most contractors prefer mobile type drum mix plants. Because they are flexible. You can quick relocate the plant between job sites. It is perfect for Philippine diverse and often remote road projects.

The asphalt drum mix plant is widely used in Philippines for township roads, provincial highways, and small to medium-scale paving projects. The mobility of mobile drum plant is a major advantage. Especially in areas with scattered construction site, such as rural and island road networks, it is ideal. Once a project is completed, you can transport the plant easily to the next location. This reduces downtime and improves efficiency. For Philippine contractors, who need to handle multiple infrastructure projects across different regions, the mobile drum mix plant is a cost-effective choice.

Daswell Popular Mobile Drum Mix Plants for Philippine Asphalt Production

| Model | Capacity(t/h) | Weighing Accuracy(%) | Total Power(kw) | Fuel Consumption(kg/t) | ||

| Aggregate | Asphalt | Coal | Oil | |||

| MADP-40 | 40 | ±1.5% | ±1% | 75 | 10~13 | 5.5~7 |

| MADP-60 | 60 | ±1.5% | ±1% | 128 | 10~13 | 5.5~7 |

| MADP-80 | 80 | ±1.5% | ±1% | 165 | 10~13 | 5.5~7 |

| MADP-100 | 100 | ±1.5% | ±1% | 200 | 10~13 | 5.5~7 |

Why Daswell Drum Mix Asphalt Plants Are the Preferred Choice for Contractors in Philippines?

Daswell has traded drum mix asphalt plant in over thirty countries, including Philippines, Peru, Kenya, Myanmar, Guatemala, and Pakistan. Our drum asphalt plants are popular among our customers because of its compact design, mobility, high efficiency, and affordability.

High quality machinery supply: For your small to medium scale road construction projects in Philippines, its ability to deliver consistent performance while being cost-effective makes it an ideal choice. Especially, the quick setup and ease of relocation reduce downtime between projects.

Quick response time with professional customized solution: When we receive inquiries from you, our sales team and engineer will engage with you promptly to understand your specific requirements. We provide detailed consultations on plant configurations, production capacity, fuel options, and other critical specifications, ensuring the selected model meets your projects demands. It can be sure that we can offer tailored solutions, which align with your budget and operational conditions.

Excellent reputation: There are many clients, who have purchased our drum mix asphalt plants in Philippines. And they have expressed high satisfaction with both the product quality and after-sales support. For example, one of our satisfied customers is a contractor from Northern Samar, Philippines. This contractor purchased our MADP40 drum mix plant with a 40t/h capacity for a national highway project. One of the reasons to choose our plant was our local presence.

We have an office and warehouse in Philippines. These ensure prompt installation, commissioning, and maintenance services. The local support network played a crucial role in building trust and ensuring smooth operations. The customer’s experience highlights how our on-ground expertise and responsive service contribute to successful project execution in Philippines.

Key Considerations for Purchasing a Drum Mix Asphalt Plant in the Philippines

Bitumen supply and handling

In Philippines, the bitumen is typically supplied in bulk by tanker trucks and you can pump directly into your storage tanks. It is the most convenient method of medium to large projects. However, for your remote island projects, you may need to consider drum or bagged bitumen. This requires additional heating equipment.

Fuel type selection

Most of our Philippine contractors prefer diesel fuel for its reliability and ease of use. The coal costs less than diesel fuel. But it requires more maintenance. Natural gas is clean but it is rarely chosen due to limited infrastructure and higher expense. When you decide the fuel type, considering fuel availability in your Philippine project location.

Production capacity matching

Our drum type mix plant output suits different project scales. The capacity can be 20 ton per hour to 100 ton per hour. They are suitable for your different projects scales in Philippines. If you do not know how to choose the suitable plant capacity, you can send an inquiry to us. Our engineer will provide professional solutions for you.

Environmental compliance

Our drum mix asphalt plant can meet different regulations in Philippines. For different Philippine regulations vary by location, there are various choices for you. In urban areas near to Metro Manila, we have baghouse filter. It can realize 99% dust removal.

Besides, for some provincial or rural projects, many Philippine customers choose water dust collectors.

After-sales support

As a professional asphalt mixing plant supplier, we have an office in Philippines. We can provide

It is key for you to verify the manufacturer support capabilities before your purchasing. Or you may cost more on the downtime. Choosing Daswell in Philippines, you can avoid these problems with professional machine supply.

How to choose the right asphalt mix plant for your Philippine projects, drum mix or batch mix?

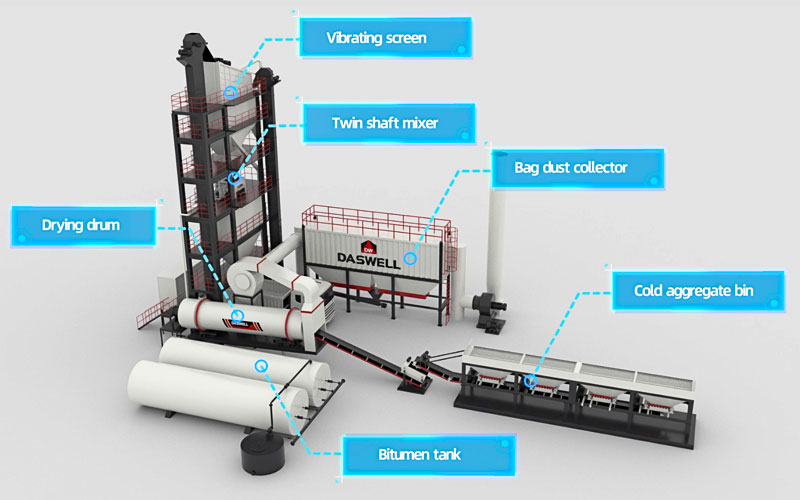

Drum mix asphalt plant and batch mix asphalt plant are two common types in Philippines. They are suitable for different road construction needs. Here you can know their key differences and it is helpful for you to choose the right type and model for your Philippine project.

Raw materials

- Drum mix plant uses aggregates and bitumen as materials, without mineral powder.

- Batch mix asphalt plant uses aggregates, bitumen, and mineral powder as materials. It ensures better binding and mix quality.

Drum mix asphalt plant is simpler and cheaper than the batch type. And it is good for low-budget projects. While, the batch mix plant is better for high-grade roads, including highways, airports, etc. These have high requirements for durability.

Weighing system

- The drum mix plant has no separate weighing system. The aggregate is weighed by adjusting the belt speed through a frequency converter, while bitumen is weighed by adjusting the flow rate of the asphalt pump.

- Batch mix plants have precise weighing systems for weighing aggregate, bitumen, and powder. This ensures accurate mix proportions.

For major infrastructure in Philippines, you can choose the batch mix plant. It can produce higher-quality asphalt. For rural or temporary repair jobs, which are less critical on exact ratios, the drum mix asphalt plant is sufficient.

Mixing system

- The drying and mixing processes happen in one drum when you choose the drum mix plant. That makes the plant simpler but less controlled.

- The batch mix plant uses a drying drum and a separate mixer for drying and mixing. The twin-shaft mixer has good excellent mixing ability. It allows better consistency.

Finished asphalt quality

- Because there is no powder and less precise mixing, using drum mix asphalt plants for producing asphalt, the asphalt will be lower quality than batching mix plant.

- Using batching type asphalt mixing plant for asphalt production, the finished asphalt quality will be superior, meeting strict road standards in Philippines.

Dust collection system

- Generally, the drum type asphalt mixing plant utilizes a water dust collector for dust collecting. It is cheaper but less efficient.

- There are two-stage dust removal for the batch mix plant. We employ cyclone and baghouse for reducing pollution better.

For some urban areas with strict emission rules, we recommend the batching type asphalt plant. If the regulations are more lenient, you can choose the drum mix plant.

Price comparison

Batch mix asphalt plant hasa higher price than the drum mix type. For long-term big projects, the batching mix plant will be better. If you are a small contractor or you use it for temporary projects, the drum plant will be an ideal choice.