Mobile Crushing Plant

The mobile crushing plant is a new type of crusher equipment that is often used in areas such as roads, railways, construction waste, etc. where processed materials need to be moved. The mobile crushing plant is an independent unit that can complete the crushing work alone, or multiple pieces of equipment can be operated together to form a powerful production line.

Mobile crushing plants: flexible, efficient, and reliable crushing solutions

Mobile crushing plants provide highly flexible and efficient solutions for on-site crushing needs. As they can be moved directly to the construction site, these crushing plants do not need to transport raw materials, saving time and money. Whether you are in a quarry, construction site, or mining operation, mobile crushing plants can handle a variety of materials, including limestone, granite, basalt, and more.

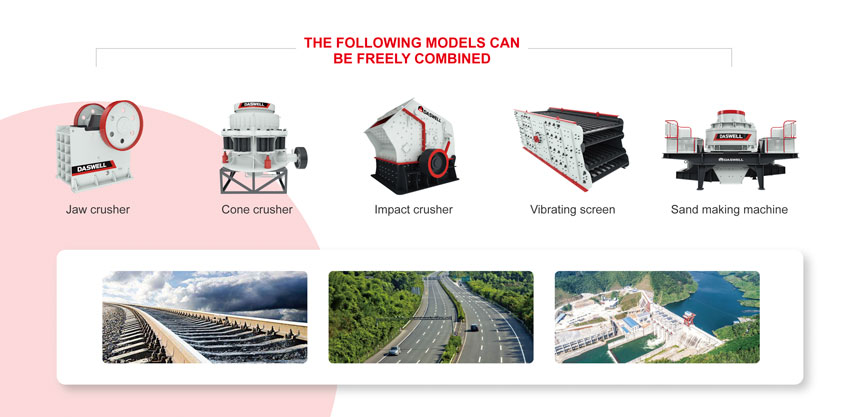

At Daswell, our mobile crushing plants are equipped with powerful crushing equipment such as jaw crushers, cone crushers, and impact crushers, and are equipped with advanced screening equipment. These mobile units can be customized to your specific production needs, ensuring high crushing efficiency, excellent product quality, and minimal downtime.

The main features of our mobile crushing plants include:

Mobility: can be easily moved to different construction sites for maximum flexibility.

High efficiency: powerful crushers and screens are designed to achieve high output.

Cost-effective: no need to transport raw materials, reducing operating costs.

Durability: with a sturdy structure to withstand harsh working environments.

Versatility: Suitable for a wide range of crushing processes from primary to tertiary.

Whether you are processing limestone, granite or basalt, a Daswell mobile crushing plant can provide the reliability and efficiency you need for your project. Contact us today to find out how our solutions can help you maximize your productivity and profitability.

Types of mobile crushing plant

Mobile crushing plants can be divided into crawler-type mobile crushing plants and tire-type mobile crushing plants according to different driving methods.

The crawler-type mobile crushing plant can be moved by itself and operated by wireless remote control. It is mostly used in mountainous areas, wetlands and harsh mining environments.

The tire-type mobile crusher plant is semi-mobile and needs to be towed by a semi-trailer when traveling. It is mostly used for construction waste disposal, earthworks, and construction.

According to different crusher machines, mobile crushing plants can be divided into mobile jaw crushing plants, mobile impact crushing plants, mobile cone crushing plants, etc.

Mobile Crushing Plant video

Daswell Mobile Crushing Plant project

Compare crawler-type and tire-type mobile crusher plants

The difference between the two mainly has the following aspects:

Moving method:

The crawler mobile crushing plant adopts a crawler chassis, which can drive stably in complex terrain and harsh environments.

The tire mobile crushing plant adopts a tire chassis and is more suitable for flat and relatively stable construction sites.

Different application scenarios:

Since the crawler chassis of the crawler-type mobile plant has excellent passability and can cope with muddy, uneven ground, and rugged mountain roads, it has more advantages in complex terrain and bad weather.

The tire mobile crusher machine is more suitable for flat sites such as urban construction.

Working efficiency:

When the tire mobile crushing plant is working, the stability of the entire plant is increased because the hydraulic legs under the frame are fixed. Stability is the basis for the operation of a mobile crushing plant. Good stability enables the entire plant to be equipped with a large-scale crusher machine. In other words, the tire crushing plant can crush large materials with high working efficiency.

The stability of the crawler mobile crushing plant is weak, so its crushing capacity is not as efficient as the tire crushing plant.

Equipment performance:

The tire-type crushing plant has a short wheelbase, a small turning radius, does not damage the road surface, and can travel flexibly in the working area.

The crawler crushing plant adopts a crawler walking mode and can realize in-situ steering. Through wireless remote control operation, it is easy to drive the crusher onto the trailer and transport it to the work site.

Its advantages

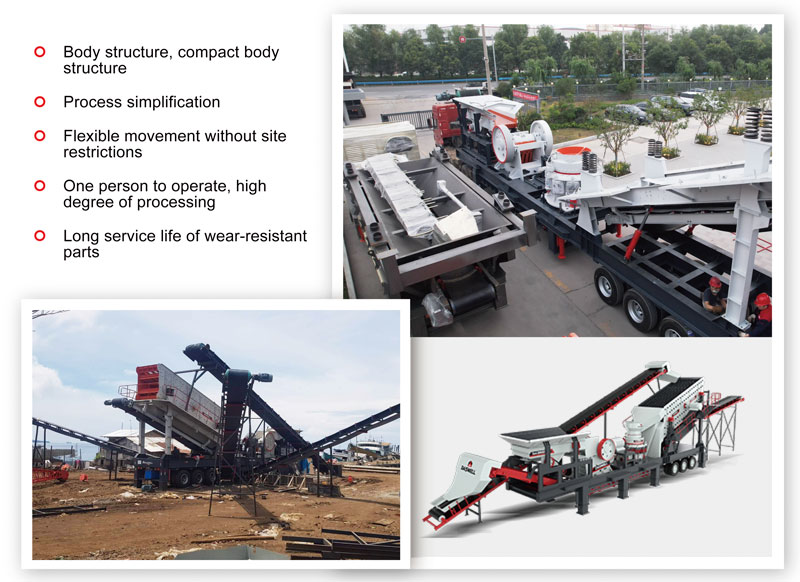

- Integrated unit with compact body structure: the integrated vehicle-mounted installation of vibrating screen, feeder, belt conveyor, and crusher is less affected by terrain factors, easy to move, takes up a small area, and does not require installation, saving foundation costs.

- Simplified process flow: One unit mobile crushing plant has multiple functions such as feeding, crushing, conveying, and screening. It is equivalent to a small stone processing plant, with strong practicality, high cost performance, and simplified process flow.

- Flexible movement, not subject to site restrictions: It can go directly into the work site and has strong adaptability. It does not need to transport materials back and forth, does not need to drive ground piles or foundation construction, saves a lot of expenses, and can drive flexibly on ordinary roads and in the work area.

- One person controls a high degree of intelligence: The mobile crushing plant is highly intelligent. The parameters are debugged in the early stage and integrated into the automatic control programming system to achieve one-click adjustment. One person can control the entire site, reducing workload and costs. In addition to the engine, it also has its own generator, which can be used in both diesel and electric modes, increasing overall output.

- Long service life of wear-resistant parts: Wear-resistant parts have a long service life, greatly reducing the frequency of maintenance, and effectively reducing usage costs.

Working principle

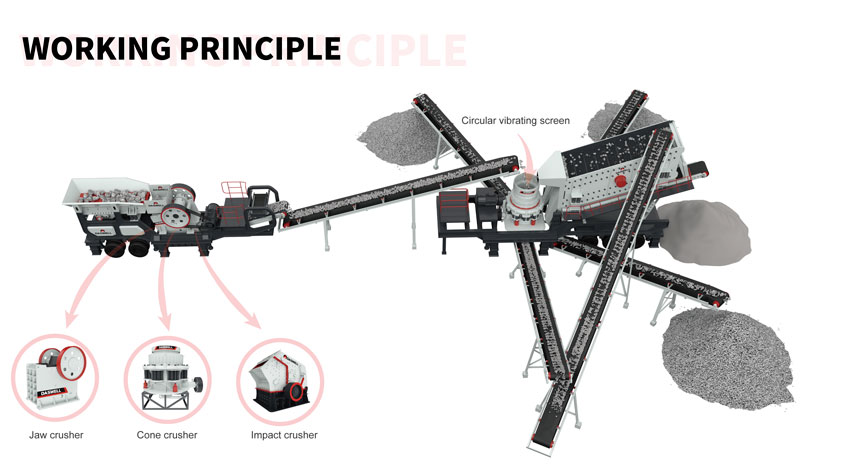

The main crusher machine of the mobile crushing plant can be a jaw crusher, an impact crusher, or a cone crusher. The material is evenly transported to the crusher through the feeder. After being initially crushed by the crusher, a circular vibrating screen forms a closed-circuit system to realize the cyclic crushing of the material. Materials that meet the particle size requirements are output by the belt conveyor to achieve production purposes.

The mobile crushing plant can also remove the circular vibrating screen according to actual production needs, directly crush the materials initially, and then cooperate with other crushing equipment to perform specific operations, which is convenient and flexible.

Cases of mobile crusher plant

Our Daswell Machinery’s mobile crushing plant has won unanimous praise from customers for its excellent quality and stable performance. In recent years, our mobile crushing and screening plants have been exported to many countries such as the Philippines, Mexico, and Peru.

Our sales and after-sales service teams not only provide customers with customized solutions, but also have 24*7 hours of online service, which can promptly solve various problems encountered by customers in production.

If you want to choose a trustworthy mobile crushing plant manufacturer, you can choose us without hesitation!