What is Calcium Carbonate Powder Used for?

Calcium carbonate powder is a versatile substance. It is a naturally occurring chemical compound found in rock. The limestone, marble, chalk, and aragonite are common calcium carbonate. It is a white, odorless, tasteless powder. And it is insoluble in water but soluble in acids. You can use it in various industries.

Main natural sources of calcium carbonate powder

Limestone: The limestone is sedimentary rock. It is the most common source.

Marble: It is metamorphic rock. It is often used in construction and sculpture.

Chalk: It is a soft, porous limestone formed from marine fossils.

Aragonite and calcite: They are different crystalline forms of CaCO3.

What is calcium carbonate powder used for?

Calcium carbonate is a fundamental material with diverse applications. Here you can learn some wide applications of the calcium carbonate powder.

Construction industry

It acts as a key filler in concrete formulations.

You can use it as a primary raw material for cement manufacturing.

It can be used as an effective coating agent for walls and ceilings.

Paper manufacturing

Using it as a coating and filling agent, it can enhance paper quality. It can improve critical paper characteristics: brightness and whiteness, opacity for better print contrast, surface smoothness for superior printability.

Plastics production

You can use it as a cost-effective filler material. It will enhance material properties by increasing structural strength, improving rigidity, and optimizing dimensional stability.

Agricultural uses

It is an effective soil amendment for neutralizing acidic soil, providing essential calcium to crops, and improving soil structure and nutrient availability.

Cosmetic formulations

It is a multi-functional ingredient, serving as a gentle abrasive in oral care products, a texture-enhancing filler in makeup, exfoliating agent in skincare preparations.

How to make calcium carbonate powder?

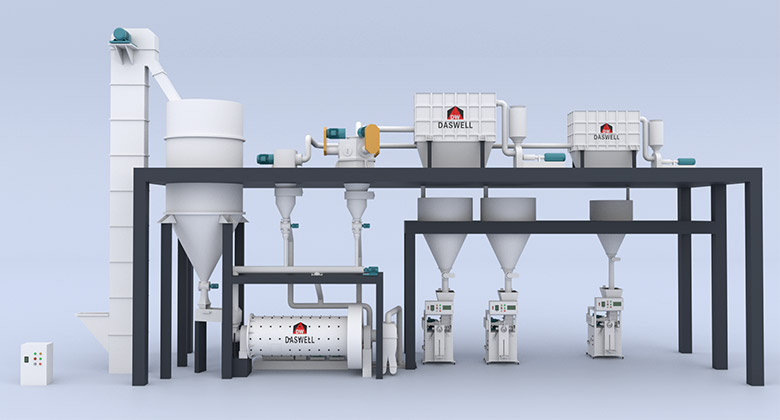

Generally, getting calcium carbonate powder, it requires fine powder grinding process. Daswell provides a full set of calcium carbonate powder mill grinding line for you. Here you can learn the processes of turn calcium carbonate into powdery products.

Raw materials preparation

High-quality calcium carbonate powder production begins with careful raw material selection and processing. It is key to prepare the calcium carbonate material. The main processes are mining and selection, drying and crushing.

The raw materials are limestone, calcite, and marble. They are extracted from quarries. Then select and clean the raw materials for removing the impurities such as clay, sand, which will affect final product purity.

Drying the washed materials for preventing moisture-related issues in grinding.

Crushing the large rocks by using the jaw crusher. It is the primary crushing. After the jaw crushing process, large rocks will be reduced to coarse fragments. For better grinding, you can use the hammer crusher for secondary crushing. It can process the rock into an ideal size for grinding mill feeding.

Grinding

Grinding process is the most crucial process for turning calcium carbonate into powder. We recommend a ball mill grinding machine for you. It can produce fine powder. And it can accept materials, whose mosh are under 7. The ball mills are the most popular grinding equipment. After crushing, the materials will be stored in a silo. And there is a vibrating feed to feeding materials into ball mill machines.

The ball mill grinding equipment utilize rotating drum and grinding media to impact and crush the material. And it is applicable for you to control the finished particle sizes according to your requirements by adjust rotating speed, grinding time and media.

Classifying, re-grinding and collecting

The final process is collecting. We have dust collector for you to collect the finished powdery products with no air pollution. Whether for collecting powder or protecting environment, it is efficient. Besides, it is alternative for you to choose the air classifier for classifying the powders. You can also adjust the air classifier for setting the size of classified powders. It is applicable to return the oversized powder into ball mill grinding facility for re-grinding. This ensure no material waste.

Daswell excellent calcium carbonate powder production system can make sure high product uniformity, energy efficiency and minimal waste. For your industry which requires tailored powder specifications, you can adjust the mill machine setting, classifier setting, and the grinding media. Just contact Daswell, customizing your calcium carbonate powder processing plant solution.

What is the use of coated calcium carbonate powder?

The coated calcium carbonate powder is a modified form of standard calcium carbonate. The particles are surface-treated with stearic acid, silane, titanate, or other agents. By coating, it can improve compatibility, dispersibility, and performance in specific applications.

Plastic and polymers: You can use it as a filler and reinforcing agent. It can improve mechanical strength such as tensile, or impact resistance. And it also enhances heat stability and reduces shrinkage. Many customers use it for replacing more expensive resins, lowering the production costs. For PVC pipes, profiles, films, polypropylene(PP) and polyethylene(PE) production.

Rubber industry: It can be used as reinforcing filler for tires, seals and hoses. With coated calcium carbonate powder, it will increase abrasion resistance and improves tear strength and elasticity. Compared with carbon black, the coated calcium carbonate powder reduces cost.

Paints and coatings: It can be used as extender pigment and matting agent. Using it for paints and coatings, it will improve opacity and weather resistance. Meanwhile, it can enhance dispersion, preventing clumping. And it is helpful for adjusting the gloss levels. Whether for matte or semi-gloss finishes requirements, you can adjust it by using the coated calcium carbonate powders.

Paper industry: For paper industry, its main function is improving brightness, smoothness and printability. It also reduces wood pulp usages.

How to coat the calcium carbonate powder?

Daswell provides coating machines for you to coat the calcium carbonate powder. Here you can learn the detailed workflow.

Feeding

The bucket elevator transports GCC powder from the ball mill machine to a storage silo. And the measured GCC powder and stearic acid another coating agent are mixed in a screw mixer. Then the mixture will be pneumatically conveyed by a blower into the coating machine.

Coating process

Inside the coating machine, it utilizes high-speed vortex system for making thorough blending and pulverization. It can enable uniform coating of the calcium carbonate particles.

Classification and recycling

After the coating, the coated powder can be sent to the classifier by airflow. The particles will be precisely sized through the air classifier. The fine and properly coated GCC will proceeds to the product silo. There is a dust collector for collecting these powders well. And the oversized or insufficiently coated particles will be rejected. They can be recycled back into the coating machine for reprocessing.

Daswell provides full set of coated calcium carbonate powder production plant for you. From the crushing, grinding to coating, we can meet your needs. Meanwhile, there are various crushers, grinding mills, and coating machines for you to choose. We can also offer you quartz powder grinding plant and talc powder production line. These are popular among our customer, especially in Egypt.

If you have interests, please send inquiry to us. Our engineer can design for you according to your factory size and layout. Getting your own calcium carbonate powder grinding production plant now!