Ready Mix Concrete Production Plant

Ready-mix concrete is key for the construction industry. It is efficient and economic. With the global demand for high-quality concrete, the ready-mix concrete production has evolved into an advanced, automated system. It ensures consistency, speed, and sustainability.

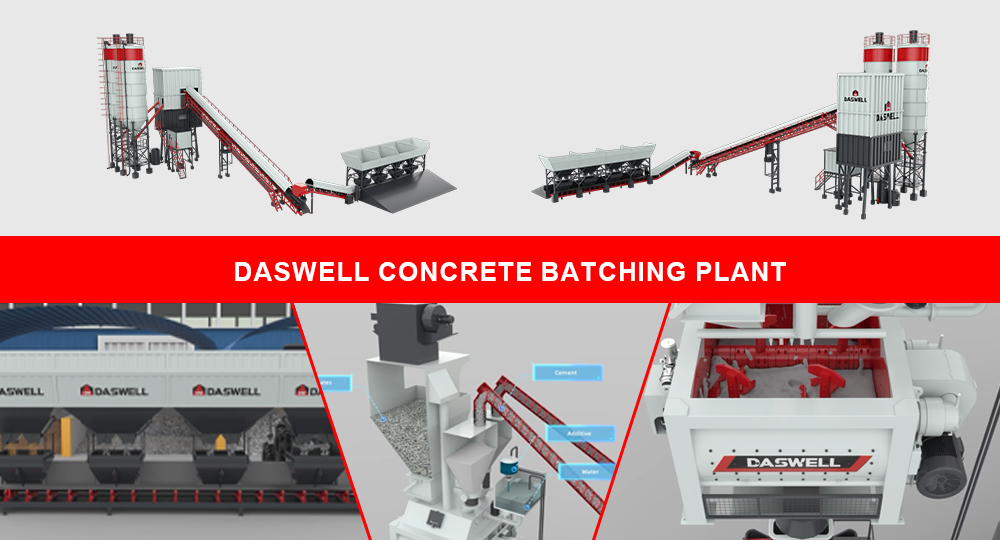

Daswell provides complete ready mix concrete plant solutions. And we combines advanced technology, reliable equipment with local service support in Philippines and Indonesia. Whether you run a large-scale commercial batching business or a mobile on-site production project, Daswell can deliver a suitable solution for you.

What is the ready-mix concrete plant?

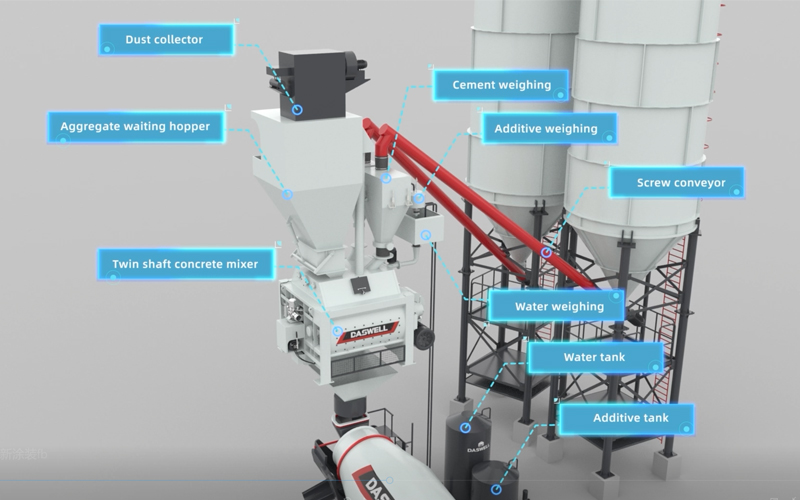

A ready mix concrete plant is also knowed as a concrete batching plant. It is mainly used for making concrete. You can prepare concrete in a factory or batching plant according to a set recipe. Different from the traditional concrete, which is mixed at the job site, the ready-mix type concrete is made in batching plants. The batching plants utilizes PLC system for batching the materials with high accuracy. This ensures precise proportions of cement, sand, aggregates, water, and additives.

When the mixing finishes, the concrete will be transported to construction sites by transit mixers. This process eliminates inconsistency and manual error. Meanwhile, it guarantees that every batch of concrete meets the desired strength, durability, and workability.

The ready mix concrete is widely used for building construction, road and bridge projects, urban infrastructure, industrial and commercial developments, etc.

What are the advantages of Daswell ready-mix concrete production plant?

Excellent consistency and quality control

The consistent quality is one of the main advantages of ready-mix concrete. Daswell utilizes advanced for controlling the accuracy. With Daswell batching plants, you can produce high quality concrete consistently.

It is different from on-site mixing. The on-site mixing may be affected by factors such as weather, experience of labor, and time constraints. Daswell ready mix concrete batching plants operate in a fully controlled environment. It can measure all the raw materials precisely with strict quality control checks during production. This makes sure uniform strength and performance.

High efficiency and time-saving

One of the biggest advantages of using Daswell ready-mix concrete plants is high efficiency. Daswell ready-mix concrete plant eliminates the need for on-site mixing. Because of the pre-mixed concrete, the workers can focus on laying the concrete without delays. This highly enhances the project timelines and productivity.

High-quality equipment

Daswell utilizes high-quality steel frames and branded components such as Siemens and Schneider for manufacturing the machines. This ensures long lifetime with minimal maintenance needs. The robust construction ensures stable operation even under harsh working conditions. Meanwhile, we provides spare parts for you, ensuring uninterrupted plant operation.

Reducing labor and equipment costs

Daswell ready-mix concrete production plant employs PLC systems for controlling the whole plant. It saves your labor costs. You do not need to employ too many workers for operating the machines.

Meanwhile, we have complete production machines, saving your time and money for buying separated equipment. This saves both time and investment. You can setup the plant faster with lower operating expenses.

Local service in Philippines and Indonesia

One of Daswell’s greatest advantages is our localized service network. We have offices in Indonesia, Philippines and some other countries. We can offer you

- Fast equipment delivery

- On-site installation and commissioning

- Regular maintenance and technical support

- Quick trobleshooting and spare parts supply

With our local engineers and service teams, you can get faster response and lower downtime. We ensures your batching business runs smoothly and efficiently.

Customized solutions

According to your different working sites, budgets, material storage, production capacity, and the workflow, we can customize your own ready-mix concrete production plant. Daswell has professional engineer with rich experience. We can design the most suitable plant for you from stationary batching plants for mobile batching plant.

Daswell cases of concrete batching plants for ready mix concrete plant

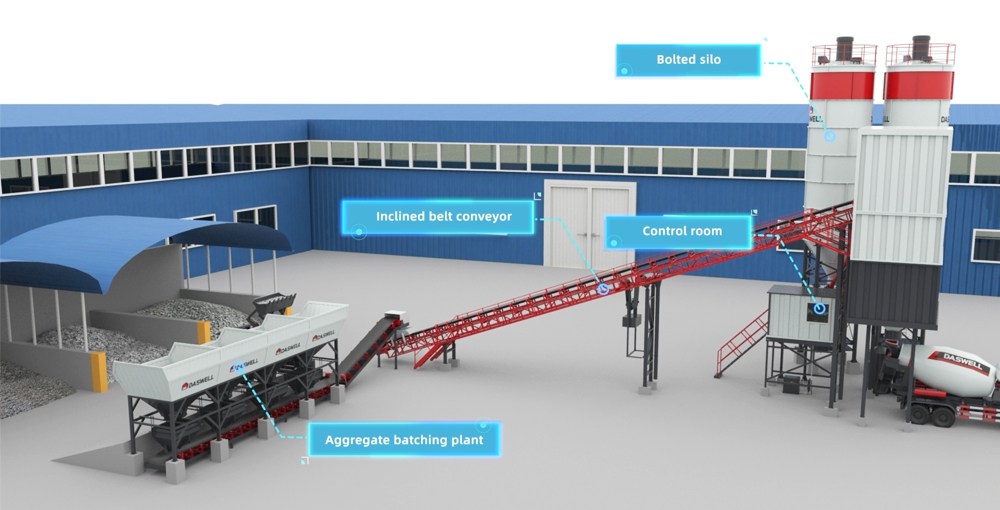

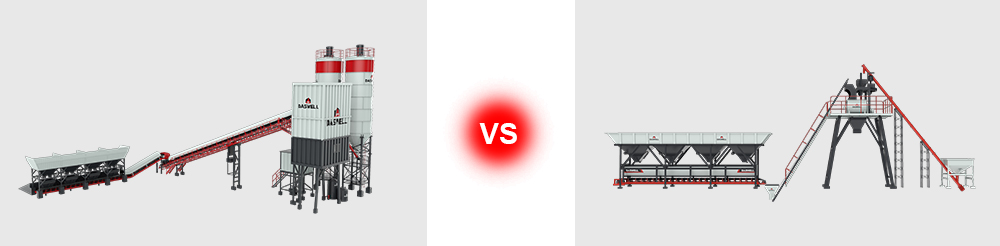

For your ready mix concrete plant business, Daswell offers you two types of concrete batching plants. Both our stationary batching plant and mobile batching plant are popular among our customers. Especially, our batching plants have great markets in Philippines and Indonesia.

The stationary concrete batching plant is suitable for long-term and large-scale concrete production. While, the mobile type concrete plant is more convenient for moving. You can move it easily between different working sites.

Daswell stationary concrete batching plant solution in Philippines

The stationary batching plant is applicable for large scale concrete making requirements. Our Philippine customer choose the CBP120 batching plant for road and urban infrastructure construction. It has high concrete production volumes and high-quality continuous feed.

The complete CBP120 batching plant includes a batching machine, main twin-shaft concrete mixer, four 100T cement silo, screw conveyor and the fully automatic control system.

From equipment selection, transportation, installation and training, Daswell offers professional support. This batching plant runs smoothly and efficiently, delivering high-quality concrete continuously for large construction projects.

Daswell mobile type batching plant working site in Philippines

Daswell MCBP60 in Philippines has been running already. It can provide high-quality concrete for local construction projects. The quick-relocation capability provides flexibility and efficiency for contractors.

Our customer praised its quick installation, mobile and compact design, and the precise batching and mixing. Meanwhile, our local service in Philippines helps our customer maintain and solve problems efficiently.

| Model | MCBP25 | MCBP35 | MCBP50 | MCBP75 | MCBP100 | |

| Capacity (m3/h) | 25 | 35 | 50 | 75 | 100 | |

| Concrete mixer | Model | TCM500 | TCM750 | TCM1000 | TCM1500 | TCM2000 |

| Mixing power (kw) | 18.5 | 30 | 18.5×2 | 30×2 | 37×2 | |

| Output per batch (m3) | 0.5 | 0.75 | 1 | 1.5 | 2 | |

| Max. aggregate size | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | ≤60/80 | |

| Aggregate bin (m3) | 2×8 | 2×8 | 4×8 | 4×8 | 4×10 | |

| Walking speed (km/h) | 20 | 20 | 20 | 20 | 20 | |

| Weighing accuracy | Aggregate | ±2% | ±2% | ±2% | ±2% | ±2% |

| Cement | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Water | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Additive | ±1% | ±1% | ±1% | ±1% | ±1% | |

| Discharge height (m) | 3.8 | 3.8 | 4.0 | 4.0 | 4.0 | |

| Total power (kw) | 40 | 55 | 75 | 105 | 135 | |

| Model | CBP25 | CBP35 | CBP50 | CBP75 | |

| Capacity (m³/h) | 25 | 35 | 50 | 75 | |

| Mixer | JS500 | JS750 | JS1000 | JS1500 | |

| Aggregate Bin | PLD800 | PLD1200 | PLD1600 | PLD2400 | |

| Discharge Height (m) | 3.8 | 3.8 | 3.8 | 3.8 | |

| Cycle Time (s) | 72 | 72 | 72 | 72 | |

| Weighing Accuracy (%) | Aggregate | ±2 | ±2 | ±2 | ±2 |

| Cement | ±1 | ±1 | ±1 | ±1 | |

| Water | ±1 | ±1 | ±1 | ±1 | |

| Additive | ±1 | ±1 | ±1 | ±1 | |

| Model | CBP60 | CBP90 | CBP120 | CBP180 | CBP240 | |

| Capacity (m3/h) | 60 | 90 | 120 | 180 | 240 | |

| Mixer | JS1000 | JS1500 | JS2000 | JS3000 | JS4000 | |

| Aggregate Bin | PLD1600 | PLD2400 | PLD3200 | PLD4800 | PLD6400 | |

| Discharge Height (m) | 4 | 4 | 4 | 4 | 4 | |

| Cycle Time (s) | 60 | 60 | 60 | 60 | 60 | |

| Weighing Accuracy (%) | Aggregate | ±2 | ±2 | ±2 | ±2 | ±2 |

| Cement | ±1 | ±1 | ±1 | ±1 | ±1 | |

| Water | ±1 | ±1 | ±1 | ±1 | ±1 | |

| Additive | ±1 | ±1 | ±1 | ±1 | ±1 | |

How does Daswell make your ready mix concrete plant more efficiently?

Accurate batching system: Daswell uses advanced weighing sensors and PLC control to ensure the precise mix ratios and uniform concrete quality.

Reliable product quality: All Daswell ready-mix concrete plants uses branded componets and robust materials. Our plants offer long lifespan and minimal maintenance.

Control system and automation: Daswell concrete batching plants PLC systems can realize real-time data monitoring of material weights, mixing time, and output volume. And it is easy for you to operate the system. This ensures high batching accuracy and stable production. It is essential for consistent concrete quality.

Engineer installation and maintenance: There are professional engineer for helping you install the whole plant. This saves your time and you can run your business efficiently. And our after-sale service makes sure your ready-mix concrete production business run smoothly. Especially, you can get local service in Indonesia and Philippines.

Environmental processing: Our cement silos and aggregate conveyors are environmental. At the same time, we adopt noise reduction technology to meet local environmental standards. You do not need to worry about the environment problems.

Choosing Daswell for your ready mix concrete production plant supplier

With strong technical expertise, advanced equipment, and local service teams, Daswell has become a trusted supplier of ready-mix concrete batching plants. We help clients build efficient, sustainable, and profitable concrete production systems.

Whether you need a stationary batching plant for long-term commercial use or a mobile batching plant for flexible on-site production, Daswell can design and deliver the perfect solution for your business.

Contact Daswell now for getting your customized ready-mix concrete plant solution, starting your high-quality concrete production business efficiently!