Dry mix concrete plant

Efficient. Reliable. Designed for Long-Distance Concrete Delivery.

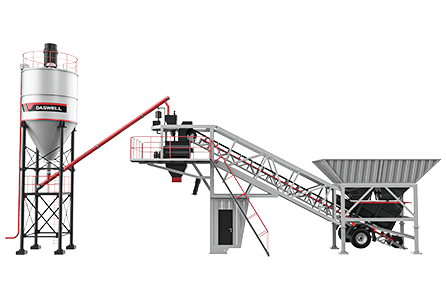

A dry mix concrete plant is a specialized and efficient batching system that combines aggregates, cement, and additives in precise proportions—without adding water—to deliver highly accurate and consistent dry concrete mixtures. The final mixing happens inside the truck mixer during transportation. With simple structure, low power consumption, and high productivity, the dry mix concrete plant is widely used in regions with long transport distances and remote construction sites.

DASWELL offers both mobile dry mix concrete plants and stationary dry mix concrete plants, providing flexible and cost-effective solutions for different project conditions.

What Is a Dry Mix Concrete Plant?

A dry mix concrete plant (also called a dry mix batching plant or dry concrete batching plant) is a batching plant without a central concrete mixer. A dry concrete batching plant measures sand, gravel, cement, and additives separately, and loads them into a truck mixer in their dry state. The truck then adds water based on the required mix ratio and completes all mixing while traveling to the job site.

The DASWELL dry mix concrete plant delivers fast batching, low maintenance, and flexible production across different concrete grades, making it ideal for high-productivity, long-distance delivery projects.

It is ideal for:

- Large concrete supply projects

- Long-distance transportation

- Regions with hot weather

- Contractors who want simple equipment and fast installation

How a Dry Concrete Batching Plant Works – Complete Working Process Explained

The working process of a dry mix concrete plant is simple, reliable, and highly efficient. The complete workflow includes:

Step 1: Aggregates are loaded into the batching plant by a loader or belt conveyor. The number of aggregate bins can be customised to match different material types.

Step 2: Each aggregate is weighed separately with high-precision sensors to ensure accurate proportions and consistent batching quality.

Step 3: Cement is stored in welded silos and conveyed by a sealed screw conveyor to the weighing hopper. Additives are measured independently for better control.

Step 4: All dry materials are discharged into the truck mixer through the hopper. Dust collection systems can be integrated to keep the site clean and compliant.

Step 5: Water is added during transportation based on the preset formula, allowing flexible adjustment for different concrete grades and jobsite needs.

Step 6: The truck drum continues rotating to complete mixing before arrival, delivering uniform, high-quality concrete ready for placement.

This workflow makes the dry mix concrete plant one of the most efficient and economical solutions for concrete supply.

Two Types of DASWELL dry mix batching plant

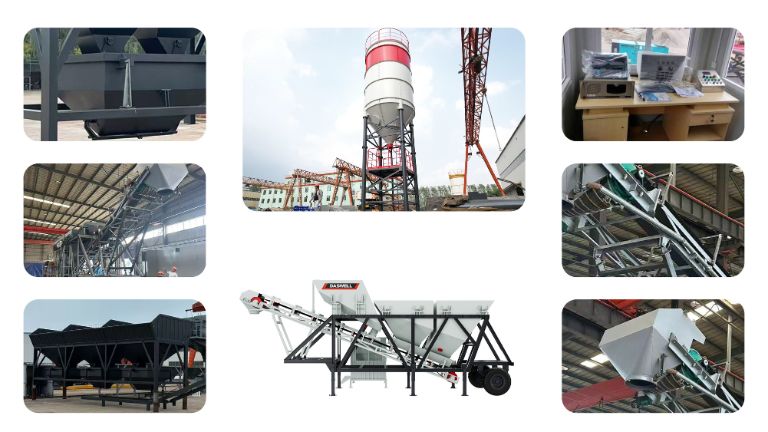

⭐ Mobile Dry Mix Concrete Plant

DASWELL mobile dry mix concrete plant integrates aggregate batching, weighing, control, and transport systems into a compact frame. It is easy to transport and install without foundation work. It features:

- Quick installation and removal

- Compact layout and Small footprint

- Ideal for temporary projects, road construction, and remote jobs

- Flexible movement and lower transportation costs

Production capacity options: 25–75 m³/h (Customizable according to project requirements.)

⭐ Stationary Dry Mix Concrete Plant

A stationary dry mix concrete batching plant offers higher capacity and long-term stability. Suitable for commercial concrete production with large daily output or long-term construction sites. Features:

- High output and stable performance

- Durable steel structure

- Designed for long service life and heavy-duty operation

- Customizable layout for local conditions

Production capacity options: 60–150 m³/h (Available in various configurations.)

Advantages of DASWELL dry mix concrete batching plant

- Efficient Batching for Centralized Concrete Supply

The DASWELL dry mix concrete batching plant eliminates the central mixer and focuses on accurate weighing and batching of aggregates, cement, and additives.

Materials are discharged directly into truck mixers, enabling fast batching cycles and making the system especially suitable for centralized concrete supply serving multiple construction sites.

- Lower Energy Consumption and Operating Cost

Without a mixer motor or mixing drive system, the dry mix batching plant requires significantly less electrical power compared with wet mix plants.

This results in reduced daily energy consumption and lower long-term operating costs, particularly for high-output commercial concrete operations.

- Simplified Structure with Reduced Maintenance

As no central mixing unit is installed, the dry mix concrete plant contains fewer mechanical components and wearing parts.

Routine cleaning and maintenance work are minimized, helping reduce downtime and extend the service life of the equipment.

- Cost-Effective Investment for Commercial Concrete Projects

Compared with wet mix batching plants, dry mix systems require a lower initial equipment investment.

Their simplified design, reduced maintenance demand, and lower energy usage make them an economical entry solution for contractors entering the commercial concrete market or operating in cost-sensitive regions.

- High-Precision Weighing for Stable Concrete Quality

With batching accuracy within ±1%, the dry concrete batching plant ensures precise control of material proportions.

Although final mixing is completed inside the truck mixer, consistent batching accuracy helps maintain reliable concrete quality during continuous and high-volume production.

- Extended Material Viability Before Final Mixing

Since no water is added during the batching process, dry mix materials avoid early hydration and premature setting.

This provides a longer and more controllable time window before final mixing, which is particularly beneficial for long-distance transportation and flexible delivery scheduling.

- Reduced Environmental Impact at Job Sites

By eliminating wet mixing at the batching plant, dry mix systems significantly reduce wastewater and slurry generation.

This simplifies environmental management and supports compliance with local environmental and sustainability regulations.

- Suitable for Special Concrete Mix Designs

Dry mix batching plants can be used for special concrete types such as self-compacting concrete and high-performance concrete, provided that appropriate mix designs and adequate truck mixer performance are applied.

This offers flexibility for producing diversified concrete products.

- Ideal for Long-Distance and Remote Concrete Delivery

Water addition and final mixing are performed inside the truck mixer during transportation. This prevents early setting of materials and makes the dry mix concrete plant especially suitable for long-haul delivery and remote construction sites.

- Modular Design, Fast Installation, and Automated Control

The modular plant structure allows quick installation, relocation, and future capacity expansion.

Equipped with PLC control systems and high-quality electrical components, the batching plant dry mix delivers stable, fully automated operation and long-term reliability.

Components of a DASWELL batching plant dry mix

Each dry mix concrete batching plant consists of:

- Aggregate Batching System: High-accuracy weighing ensures good concrete quality. The optional pre-feeding system eliminates the need for a loading ramp.

- Belt Conveyor: Transfers sand and aggregates to the discharge hopper or truck mixer.

- Weighing System: Includes weighing sensors for aggregates, cement, water, and additives. Ensures precision and consistent mixing proportions.

- Cement Silo (50–500 tons): Bolted or welded silos for storage of cement or fly ash. Compatible with bagged or bulk cement feeding.

- Control System: Full-automatic control with real-time monitoring, fault detection, and production data management.

- Truck Mixer Interface: All materials are discharged into the truck mixer for final wet mixing.

All key components use branded electrical parts to guarantee stability and high accuracy.

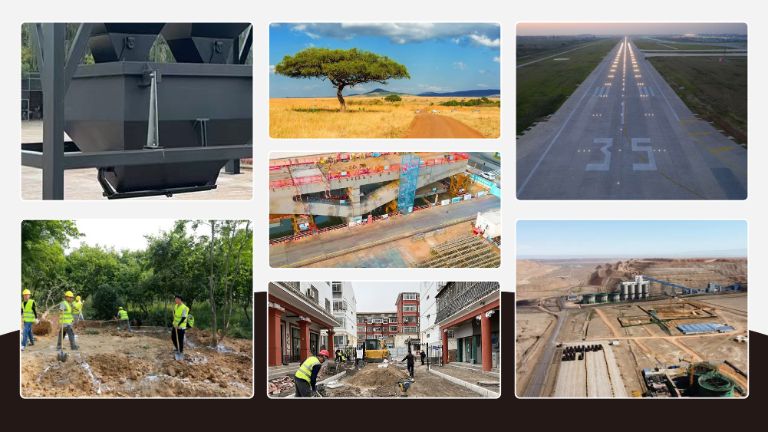

Applications of Dry Mix Concrete Plant– Ideal Use Cases & Project Types

DASWELL dry mix concrete batching plant is widely used in:

- Commercial concrete supply

- Long-distance delivery projects

- Hot climate regions

- Road & bridge construction

- Housing projects&Municipal engineering

- Foundation work&Airport runways

- Mining and infrastructure projects

DASWELL dry concrete batching plant Price

The price of a dry mix concrete plant depends on:

- Production capacity

- Number of cement silos

- Aggregate batching configuration

- Electrical component brands

- Mobility (mobile or stationary)

DASWELL offers models from 25–150 m³/h, supporting customized solutions. Contact us to get a precise quotation based on your project needs.

Why Choose DASWELL Dry Mix Concrete Plant?– Brand Strength & Competitive Advantages

DASWELL provides complete solutions for dry mix concrete plant production, including design, manufacturing, installation, and after-sales support.

Contact DASWELL today and let us be your partner in building a more efficient future.