DASWELL DMP50 Concrete Mixer Pump for Ghana

- Time: Jan 31 (Vessel departure)

- Destination: Ghana

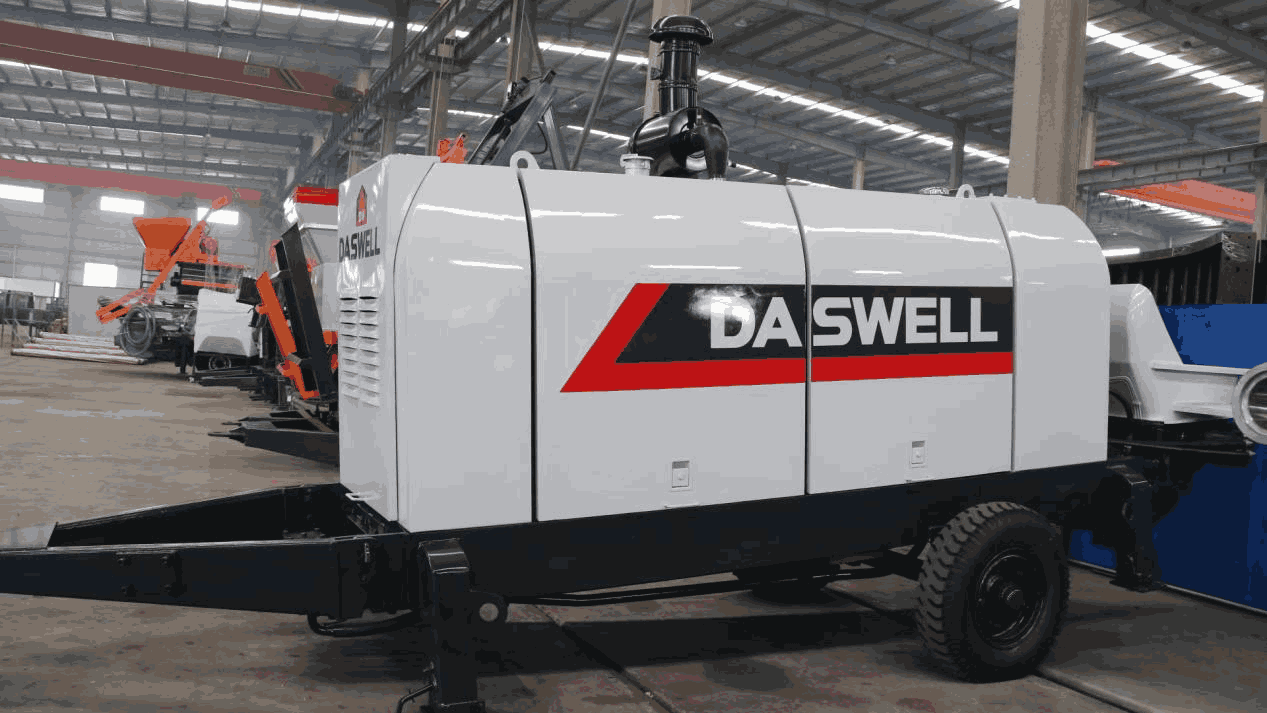

- Equipment: DASWELL DMP50 concrete mixer pump

- Quantity: 1 unit

- Customer need: Mix and pump with one machine, keep pours steady, reduce site coordination

- Solution: DMP50 concrete mixer pump for a simple “mix → pump” workflow on site

Concrete Mixer Pump: What the Customer Needed

The customer’s goal was not “the biggest output.” It was steady concrete at the hose. For many contractors, the real problem is interruptions—when the crew is ready to place concrete, but supply is not keeping up.

Two practical concerns drove the decision:

- Too many steps slow down the pour. If mixing, transferring, and pumping are handled by separate equipment, it adds handoffs. Handoffs create waiting. Waiting creates rushed work later.

- Sites can be tight and the work area can change. A compact trailer unit is easier to place, easier to manage, and easier to move when the work zone shifts.

So the customer wanted one machine that supports a repeatable routine: load materials, mix, and pump—without constant switching between different equipment.

DASWELL Solution: DMP50 Concrete Mixer Pump

DASWELL Group supplied the DMP50 concrete mixer pump in trailer configuration. The value is straightforward: one unit combines mixing and pumping, which reduces coordination on site.

How the concrete mixer pump fits real jobsite work:

- Mix + pump in one workflow: fewer transfers means fewer chances to interrupt the pour.

- Jobsite flexibility: the trailer design makes positioning and relocation easier as site conditions change.

- Clear operating routine: a fixed sequence helps different operators follow the same steps, which is important during busy pours.

Many customers choose a concrete mixer pump because it lets them start pumping on site without setting up a full batching plant.

Why the Customer Choose Concrete Mixer Pump

- Less coordination: the customer wanted to avoid running multiple machines just to feed a pump.

- Balanced, practical setup: the concrete mixer pump is often selected for jobs that need a capable but manageable unit.

- Clear shipment and handover: delivery is part of the risk. Buyers want a smooth process, not surprises at the final stage.

- Supplier support: customers want help with commissioning, operator training points, and basic maintenance planning.

DASWELL’s approach was simple: match the equipment to the customer’s workflow, then make the shipment and handover steps clear.

Shipment & Handover for Concrete Mixer Pump

This unit shipped on the Jan 31 vessel. To help the customer move faster after arrival, DASWELL Group provides a clear handover package. Typical items include:

- Packing list and shipment document set

- Operation and maintenance documents

- Guidance arrangement for installation/commissioning (as agreed)

Good handover documents save time at the next step—on-site setup and first start-up.

What a Concrete Mixer Pump Improves on Site

In real use, buyers usually care about changes they can feel immediately:

- Less waiting during pours because mixing and pumping follow one routine

- Cleaner site organization because fewer separate machines are needed

- More predictable work rhythm for the crew, especially when schedules are tight

A concrete mixer pump is mainly a “workflow machine.” It helps the team keep concrete moving with fewer interruptions.

Related Solutions from DASWELL Group

If your projects grow beyond a single concrete mixer pump, DASWELL Group can supply related equipment for different jobsite setups:

- Mobile concrete batching plant: for larger on-site batching demand

- Self loading concrete mixer: for remote sites needing loading + mixing + transport

- Stationary batching plant: for long-term projects with fixed location needs

If you are considering a DMP50 concrete mixer pump for Ghana, tell us your basic application (foundation, slab, roadwork, drainage) and site access conditions. We will recommend a configuration that fits your crew’s routine and helps you pump concrete smoothly on site. Contact us today!