Brick machines successfully assisted residential community construction projects in the Philippines

Background

For a residential development project in a city in the Philippines, a client selected a fully automatic brick machine as its core production equipment. The project required a stable, high-quality supply of concrete blocks and bricks for the large-scale residential development within a tight deadline. Our machine was the ideal choice due to its high degree of automation, high production output, and excellent molding quality.

We not only provided customers with the main brick machine, supporting mixing system, belt conveyor equipment, and molds, but also dispatched a professional technical team to carry out installation, commissioning and operation training to ensure the smooth commissioning of the equipment at the construction site.

Customer Information

The client is a well-known local construction contracting company in the Philippines. They have long been undertaking large-scale residential communities and municipal engineering projects, and are particularly good at residential buildings and commercial supporting projects. As the scale of the project expands, the client urgently needs an efficient brick machine production line to ensure the supply of building materials.

Customer Needs and Difficulties

1.Tight schedule: The residential complex’s construction schedule required a rapid delivery of large quantities of wall blocks within a short period of time.

2.High quality requirements: Bricks must meet standards for pressure resistance and wear resistance to ensure building quality and longevity.

3.Constrained construction site: Limited site space required a compact equipment layout and efficient operation.

4.Cost control: Maintaining production output while reducing labor costs and raw material waste was crucial.

To achieve this, the customer required a fully automated, stable, and high-yield brick-making system that could handle all aspects of production, from raw material transportation and mixing to forming and curing.

How Customers Find Us

The client first learned about Daswell through our Facebook carousel ads and public page. After browsing our official website and seeing our successful cases in the Philippines and Indonesia, they contacted our sales team via email and phone. After several rounds of technical discussions, solution comparisons, and video demonstrations, the client expressed their approval of the Daswell brick machine’s performance, automated control system, and comprehensive after-sales service, ultimately deciding to purchase our equipment.

Customer Purchase List

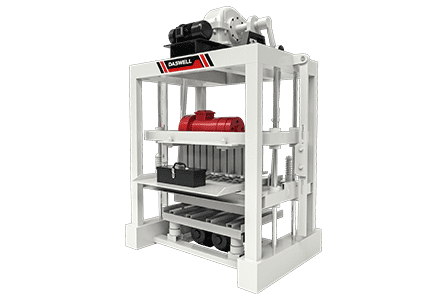

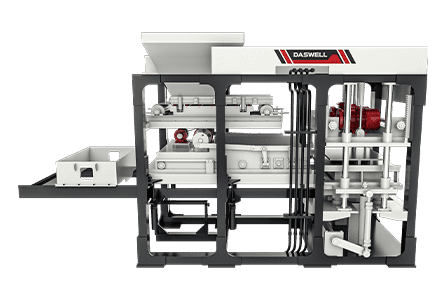

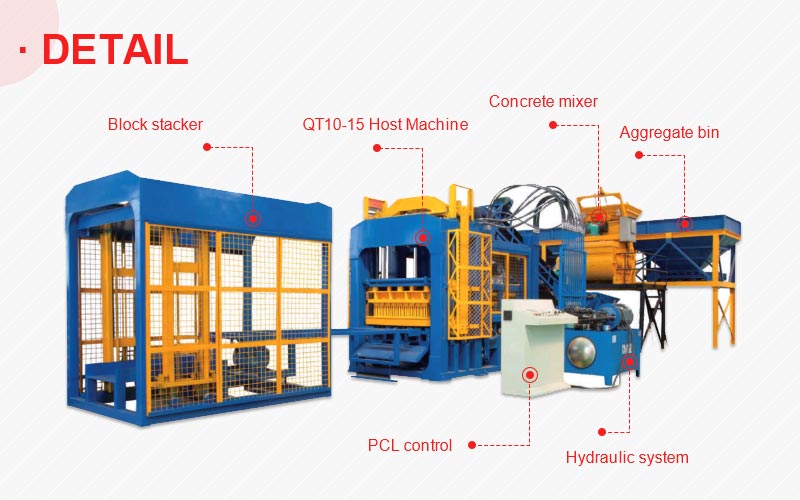

Equipment Name: Fully Automatic Concrete Brick Production Line

Model: QT10-15

Production Capacity: Up to 14,400 standard bricks/8 hours

Main Configuration:

One main machine

One JS750 concrete mixer

One automatic batching system

Two conveyor belts

Hydraulic station and electronic control system

Multiple sets of standard molds (hollow bricks, solid bricks, and paving bricks)

Auxiliary Equipment: Stacker, curing rack, etc.

Installation and debugging process

After the equipment arrived in the Philippines, Daswell dispatched a technical team to the construction site. We provided full support throughout the entire process:

1.Transportation and Unloading: We ensured the equipment was safely transported to the site and provided guidance from our technicians on proper placement.

2.Installation: This included the precise installation of the main unit, mixing system, hydraulic system, and electrical control cabinet.

3.Commissioning: We conducted a trial run and adjusted the hydraulic system pressure and vibration parameters to ensure that the bricks were densely formed and accurately sized.

4.Training: We provided operational and routine maintenance training to our customer’s workers to ensure they could use the equipment independently and efficiently.

Customer Feedback and Results

Increased Output: After the equipment went into production, it can consistently produce over 15,000 standard bricks per day, significantly shortening the project timeline.

Stable Quality: The resulting bricks are precisely sized and dense, meeting project quality requirements.

Cost Savings: Compared to traditional semi-automatic equipment, labor costs are reduced by approximately 40%, and overall production costs are reduced by 20%.

Increased Profits: The project’s input-output ratio has significantly improved, generating higher profits for customers.

The customer said that Daswell’s brick machines not only made their project construction smoother, but also enhanced their competitiveness in the local market. They plan to continue to cooperate with Daswell in future projects.