What does a concrete plant do?

The concrete plant is also known as a concrete batching plant or mixing plant. It is a set of industrial facilities. The plant is designed to produce ready-mix concrete. These facilities will combine cement, water, aggregates, including sand, gravel, or crushed stone, and chemical admixtures in precise proportions.

Choosing Daswell concrete plant, it can ensure consistent quality, strength, and durability of concrete. These features are essential for modern construction projects. Whether for your buildings, highways, bridges, and dams, you can use Daswell concrete batching plant for concrete production.

Key functions of using a concrete plant

The concrete plant serves as the backbone of modern construction. It ensures the efficient and precise production of ready-mix concrete. The primary functions of the concrete plant include batching raw materials, mixing materials into a uniform consistency, and delivering high-quality concrete to construction sites.

These operations are critical for maintaining structural integrity, meeting project timelines, and minimizing material waste. Here you can learn three core functions of using a concrete plant in detail.

Precise batching of raw materials

Making sure accurate batching of raw materials is the first and most crucial function of a concrete plant. The quality of the finished concrete mainly depends on the correct proportions of the cement, water, aggregates, and chemical admixtures. It is key for you to make sure the accurate batching for your concrete making business.

Daswell modern concrete plants use computerized weighing systems for measuring each component with high precision. It ensures compliance with mix deign specifications. It is convenient and high efficient for your concrete batching requirement. The cement and aggregates are stored in silos and bins. Daswell provides bolted silos for you to store cement conveniently. As for the aggregates, we have batching bins.

For better operation, we utilize advanced control panels for minimizing human error. This ensures consistency across batches. Proper batching makes your concrete production better. You can avoid weak concrete, cracking, or segregation. Each of these issues may influence structural safety.

Uniform mixing for consistent quality

After the materials batching, the next critical function is mixing them into a homogeneous concrete blend. For your different requirements, we have various mixing machines for you to choose. The mixing process can promise uniform distribution of all components to meet strength and durability requirements.

For a concrete supplier, it is key for you to check the quality, such as slump tests and compressive strength tests. They are conducted to verify consistency before dispatch.

Efficient delivery

The final key function of the concrete plant is timely delivery and logistics management. Because of the speciality of the concrete(It may set after 90 minutes typically), the concrete has a limited working time. It is essential for you to solve the transportation problem.

Daswell has a transit truck for making sure efficient transportation. It is equipped with a rotating drum to prevent segregation during transit.

These are three key functions of a concrete plant: precise batching, uniform mixing, and efficient delivery. They work together to produce high-quality ready-mix concrete for construction projects. Especially, Daswell concrete plant machines utilize automation and advanced technology.

Choosing Daswell concrete plant, you can enhance accuracy, reduce waste, and improve productivity, making them indispensable in the construction industry. Using Daswell concrete plant, you can produce concrete for skyscrapers, highways, or precast elements. Our concrete plants help you achieve durability, efficiency, and compliance with engineering standards.

How does a concrete plant work for producing concrete?

The concrete plant controls processes carefully. It ensures consistency, quality, and efficiency. From raw material storage to final delivery, each step is optimized to meet construction demands. The whole concrete plant’s working processes are mainly batching and mixing.

Materials Batching Process

Generally, the raw materials will be stored in the bins and silos. There are bolted silos for storing the cement better. It can prevent moisture adsorption. As for the different-sized aggregates, they are kept in separate compartments. The water and some other admixtures are stored in tanks.

All these materials have their own weighing systems for accurate batching. The batching system adopts Japanese SMC cylinder and Amcells Corp sensor.

Batched Materials Mixing Process

After the batching process, the materials will be transferred to a mixer machine. The mixing equipment will blend the batched materials into a uniform concrete mixture. Generally, our customers choose twin-shaft mixing machine for the mixing process. It can provide high-intensity mixing for high-strength concrete. For your different mixing requirements, we also have vertical planetary concrete mixers for you to choose.

For your reference, if you want to add water or admixtures, you can add them before discharging. After the mixing process, you can discharge the mixed fresh concrete for transporting or pumping directly.

If you want to transport the fresh concrete, we have transit trucks for continuous agitation to avoid segregation during transit.

For your pumping requirements on-site, Daswell offers you various concrete pumping machines. The trailer pump is popular for concrete placement. Especially, for your high-rise construction, the boom pump truck is also available.

Different Types of Concrete Plant for Your Concrete Plant

Daswell has two types of concrete plants according to the mobility. The stationary concrete batching plant has a higher output capacity than the mobile type. But it is worth to mention that the mobile type concrete batching plants are convenient for you to move the plant easily. If you need rapid installation and have requirements on relocation, the mobile concrete plants are ideal for your project.

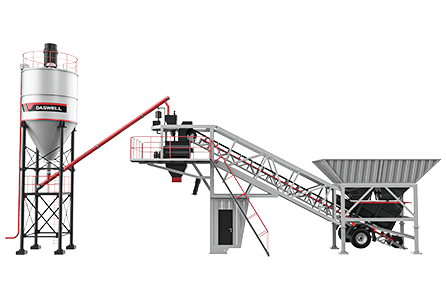

Popular mobile type concrete batching plant for sale

Mobile concrete batching plant is also called portable concrete plant. For your flexible and efficient concrete making requirements, this plant is applicable. With this plant, you can setup conveniently and fast. We utilize modular design for you to assemble and disassemble it easily. It can be ready for production within hours.

Because of the compact structure, you can move it effortlessly. It only needs 1-2 trailers for transporting the whole plant. For your projects, which demand frequent relocation, the mobile batching plant is perfect.

Stationary concrete batching plant with Large Capacity

Compared with the mobile batching plants, Daswell stationary batching plants are more suitable for large scale concrete making business. Both the stationary and mobile type concrete plants are automatically controlled. The biggest difference of these two types of plants is the mobility. Using a stationary plant for concrete making, you should install it fixedly. It may cost more labor and time. For your stationary concrete plant choosing, there are belt conveyor plants and bucket hopper plants in Daswell.

Compact Skip hopper type stationary concrete batching plant

The skip hopper concrete plants takes less space than the belt conveyor type concrete plant. It utilizes high-speed skip hopper for transferring the aggregates, ensuring rapid material feeding. And this also accelerates production time. It is particularly suitable for small commercial buildings, residential construction, and road projects.

High Efficient Belt conveyor type stationary concrete plant

For larger infrastructure projects, the belt conveyor type concrete plant can deliver unmatched efficiency. Its capacity is higher than skip hopper plant. Especially, the fully sealed belt system reduces dust emissions. Thus, you do not need to worry about the pollution. Meanwhile, using belt conveyor concrete plant, it can ensure uniform material distribution. It is key for improving the concrete quality and structural durability. You can use it for large precast concrete production, highways, bridges, and industrial or port developments.

Whether you need to move concrete plant frequently, or you want to own a plant with a large capacity, Daswell can meet your needs. You can select ideal plants according to your requirements.

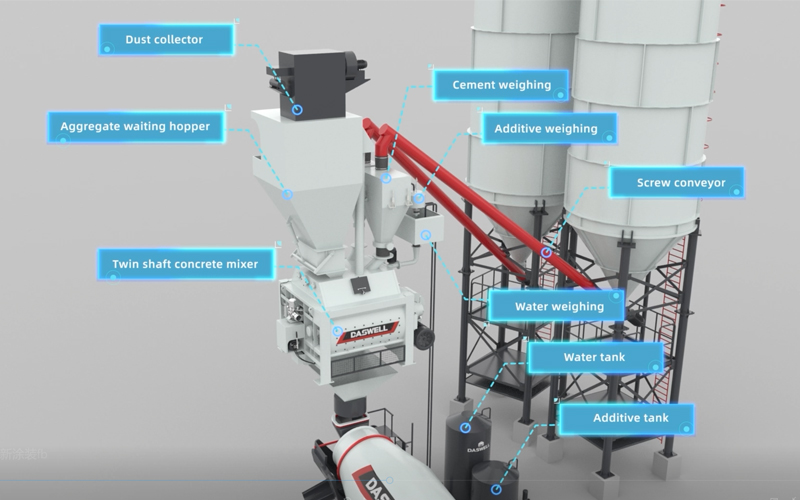

Key Components of a Concrete Plant

A concrete batching plant is a complete system. It is composed of several essential components, which work together for producing high-quality concrete. Each element plays a critical role in ensuring efficient operation, precise material proportioning, and consistent output.

Material Storage and Handling Systems

Daswell concrete plants have good ability to store and handle raw materials properly. It mainly includes cement silos, aggregate bins, water storage tanks, admixture tanks and transferring system.

Cement silos: They are tall, cylindrical structures. Daswell bolted silos can be installed simply. And the capacity can be 50tons to 200tons. You can use them for store different cement.

Aggregate bins: There are multiple compartments for storing various sizes of aggregates. They are made of heavy-duty steel. It is alternative for you to choose 3 to 4 compartments for storing materials.

Water storage tanks and admixture tanks: These tanks are used for storing water and admixtures.

For transferring the materials, Daswell concrete plants are equipped with belt conveyor or bucket hopper for transporting the aggregates. For cement transferring, there are screw conveyor. As for the water and admixtures, we utilize a pumping system.

Batching and Mixing Equipment

The batching machine of the concrete batching plant is mainly composed of storage hopper, weighing hopper and belt conveyor. The batching system adopts Japanese SMC cylinder and Amcells Corp sensor. For weighing the materials, we have cement measurement, water measurement, admixture measurement, aggregate measurement, fly ash measurement, etc. The sensor of the metering system adopts the Amcells Corp, and the powder butterfly valve adopts the Sicoma brand.

Various Concrete Mixers for Different Concrete Production Requirements

In a concrete plant, the mixing machine is a critical equipment. It influences the concrete quality. Daswell has various concrete mixers for your different concrete production requirements.

Daswell provides horizontal, vertical, and drum mixer machine for your different concrete mixing requirements. The horizontal twin-shaft mixing machine is applicable for high-intensity concrete mixing use. The vertical planetary mixing machine is more suitable for high-performance concrete making. And the drum type mixing machine is often used for mobile type concrete batching plants.

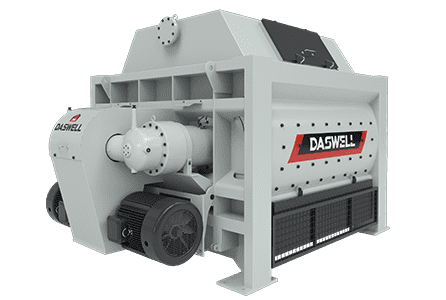

Widely used horizontal twin shafts concrete mixing machine

For large-scale concrete production, the twin-shaft horizontal mixers provide faster mixing speed than the planetary models. It is mainly designed for stiff, fiber-reinforced, and heavy-duty concrete. Using this mixer in concrete plant, it ensures uniform distribution of coarse aggregates and additives.

The twin-shaft mixer is powered by an electric motor. It is popularly used among our customers, who own a concrete batching plant. The durability and high output capacity make it a good choice for large commercial and government projects.

High-grade vertical planetary concrete mixers

The planetary concrete mixer is engineered to deliver superior mixing quality. Making high-grade concrete, this mixing machine is an ideal choice. It is excels in handling viscous, adhesive, and decorative concrete. Using this machine, it ensures homogeneous blend with minimal material segregation.

These planetary concrete mixing equipment are electric-powered. They offer energy efficiency and consistent performance in batching plants. Its unique planetary motion mixing method provides thorough mixing. It is crucial for precast concrete, architectural elements, and high-strength applications.

Portable diesel drum concrete mixer

This drum mixer is specially used for remote sites. Different from the planetary and twin shafts mixing machines, this drum mixing equipment utilizes a diesel engine for driving. If you want to run your business in areas with unstable electricity supply, this diesel drum mixer is an ideal choice for you. It is also called portable concrete mixer.

This machine features a rotating drum design. It can blend aggregates, cement, and water efficiently for standard concrete applications. While, it should be mentioned that, the drum mixer is lack of advanced mixing capabilities of planetary or twin shafts mixers. The mobility and fuel efficiency make the drum mixing facility indispensable for remote or decentralized construction sites.

Main differences between Daswell concrete mixers

| Feature | Planetary Mixer | Twin-Shaft Horizontal Mixer | Diesel Drum Mixer |

|---|---|---|---|

| Mixing Mechanism | Rotating blades with planetary motion | Two counter-rotating shafts with blades | Rotating drum with fixed blades |

| Best For | Viscous, adhesive, decorative concrete | Stiff, fiber-reinforced, heavy-duty mixes | Standard concrete mixes |

| Mixing Quality | Superior homogeneity for specialty mixes | Excellent aggregate distribution | Good for basic mixing needs |

| Mixing Speed | Moderate | Fastest | Slowest |

| Power Source | Electric | Electric | Diesel |

| Mobility | Stationary | Stationary | Portable |

| Energy Efficiency | High | High | Lower (fuel-dependent) |

| Ideal Projects | Precast, architectural elements | Large infrastructure, industrial floors | Remote sites, small/medium projects |

| Price Range | Higher | Highest | Most affordable |

| Projects Suitability | Urban projects with stable power | Large batching plants | Rural/off-grid locations |

Daswell has a complete concrete plant for your concrete projects. Whether you need mobile or stationary, large capacity or small capacity, high-grade concrete mixing needs or fast mixing speed, electric mixing or diesel engine, Daswell can meet your needs. Meanwhile, we can provide different equipment configurations according to your budget, plant scale, and concrete production requirements.

Especially, whether for transportation or pumping, we also offer various choices. We also have branches in many countries. You can visit our offices in the Philippines, Indonesia, Egypt, etc.

If you are looking for a professional concrete machinery manufacturer, just send an inquiry to Daswell. We have been manufacturing and trading concrete machines for many years in different countries.