What is the difference between the concrete mixers and concrete pumps?

Concrete mixers and concrete pumps are key equipment for your concrete construction projects. They are mainly different in the functions. The concrete mixers are mainly used for producing concrete. And the concrete pumps are used for concrete pouring. Generallay speaking, the concrete mixing machine is the production equipment. It solves your concrete production. While, the concrete pumping is the delivery equipment. It helps you transport and pour the concrete.

Main difference between concrete mixers and pumps

| Aspect | Concrete Mixer | Concrete Pump |

|---|---|---|

| Primary Function | Mixes raw materials (cement, aggregates, water) to produce fresh concrete. | Pumps pre-mixed concrete to construction sites (e.g., high-rise or distant locations). |

| Stage in Process | Used in the batching/mixing phase. | Used in the placement/pouring phase. |

| Dependency | Can operate independently. | Requires a mixer or ready-mix truck to supply concrete. |

| Key Applications | Small-scale projects, on-site mixing, or part of batching plants. | Large-scale projects, high-rise buildings, tunnels, or hard-to-reach areas. |

| Main Types | – Drum mixers – Twin-shaft mixers – Planetary mixers | – Boom pumps (with robotic arms) – Traier pumps(can be towed) – Concrete pump with mixer machines(mixing and pumping) |

| Output Focus | Ensures homogeneous concrete quality. | Ensures efficient delivery and precise placement. |

| Mobility | Portable (e.g., truck-mounted mixers) or stationary. | Highly mobile (boom pump trucks) or towed (trailer pumps with pipelines). |

What are concrete mixers and concrete pumps?

Concrete mixer is a critical machine for concrete production. It combines cement, water, sand and aggregates to produce concrete. With this machine, you can get fresh and homogeneous concrete. It ensures all the materials are thoroughly before you use it in construction. For your batching plant, the concrete mixer machine is a key equipment. It is essential for projects, which requires freshly mixed concrete on-site.

Concrete pump is a pumping machine for construction making. It transports liquid concrete from the mixer or truck to the exact pouring location. Daswell concrete pump machine utilizes hydraulic pressure to push the concrete through pipelines or hoses. There are various pumping machines in Daswell for your different requirements. You can use it for high-rise buildings, bridges, and so on.

Different functions of concrete mixers and concrete pumping machines

Concrete mixers and concrete pumps play different roles in construction projects.

The mixer machine is primarily responsible for combining raw materials, including cement, water, aggregates, and additives to produce fresh, homogeneous concrete. It focuses on the materials preparation and quality control for concrete production.

And the main function of concrete pumping machine is transporting and precisely placing the mixed concrete to specific locations on the job site. It optimizes placement speed, accuracy, and labor efficiency for the concrete placement.

They form a complete system in construction projects. The mixes create concrete. And the pump machines ensure their effective distribution, significantly enhancing productivity in modern construction projects. The functional separation makes each machine indispensable for different processes of the concrete work, from mixing to final placement.

It is worth to mention that, Daswell has advanced concrete mixer with pumping machine for you. It can meet your needs on mixing and pumping simultaneously. This machine combines the mixing and pumping functions together. It is popular among our customers in Philippines, Indonesia, Egypt and so on.

Whether you have interests on the concrete mixers, concrete pumps or our integrated concrete mixer pump machines, just contact Daswell for more details and we can offer you factory price with quality assurance.

Daswell Various Choices of Concrete Mixers and Concrete Pumps for Your Projects

As a professional concrete machinery manufacturer with rich experience, Daswell has various types of concrete mixers and pumping machines for you to choose. They are suitable for your different projects. You can know them better here for selecting the best machine for your project.

Daswell Hot Selling 5 Concrete Mixer Machines

Self Loading Concrete Mixer

The self loading concrete mixer machine combines the functions of material handling, precise batching, efficient mixing, and transporting into a single intelligent machine. It adopts four-wheel drive and compact design.

You can operate it in confined spaces and remote locations where traditional concrete plants cannot access. It is ideal for rural construction, infrastructure projects, and small-scale developments. Meanwhile, the self-loading mixers eliminate ready-mix dependency. And it also reduces labor costs and material waste.

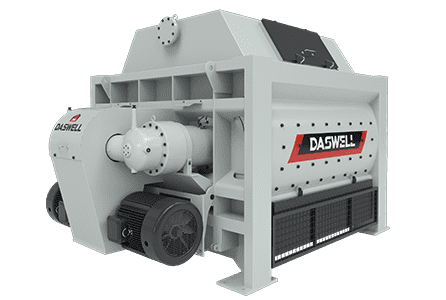

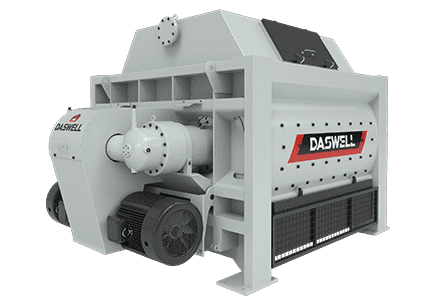

Twin-shaft horizontal concrete mixer

A twin-shaft horizontal mixer is a high-efficiency mixing equipment. It is designed for producing homogeneous concrete, mortar, and other construction materials.

The horizontal design allows for full discharge with minimal residue. Especially, the robust construction handles tough mixes, including fiber-reinforced and high-performance concrete. Its discharging volume can be 500L to 4000L. It is widely used in precast plants, RMC facilities, and industrial applications.

Planetary vertical concrete mixer

Unlike the twin shafts concrete mixing equipment, the planetary concrete mixer features multiple mixing blades. It is ideal for stiff or fiber-reinforced mixes. Its discharging volume is lower than twin shaft type, about 300L to 3000L. But it can mix concrete more homogeneously.

For your UHPC production, and construction projects requiring superior mixing performance, this machine will be suitable.

Diesel Drum mixer

Diesel drum concrete mixers are versatile, mobile mixing machines. You can use it in construction projects where electricity is unavailable or impractical. The internal blades ensure thorough blending of cement, aggregates, and water. It is designed simply. It has heavy-duty steel frames, towing hitches for easy transport, and hydraulic tilting mechanisms for controlled discharge.

For rural construction, road repairs, and small-scale projects, diesel drum mixers offer reliable performance and fuel efficiency. Meanwhile, the flexibility to operate makes it applicable for remote locations.

Mixer Truck

Concrete mixer trucks, it is also known as transit mixers. It is essential for transporting ready-mixed concrete from batching plants to construction sites. There is a rotating drum for keeping the concrete properly agitated during transit. Using this mixer truck, it can prevent segregation and maintaining workability.

Their versatility makes them ideal for urban construction, road projects, and large-scale infrastructure work. It ensures fresh concrete delivery within the critical 90-minute window after mixing.

3 Types of Concrete Pumping Machine for Sale

Concrete Mixer Pump

The concrete mixer pump is an advanced construction machine that combines mixing and pumping functions into a single unit. Using this machine for you construction projects, it will highly improve your efficiency for small to medium-scale projects.

It features an integrated mixing drum that prepares concrete on-site, along with a powerful pump system. It delivers the mixture directly to the placement area through pipelines or hoses. This all-in-one design eliminates the need for separate mixers and pumps, saving time, labor, and costs. It is widely used in residential construction, rural roads, and infrastructure projects.

Trailer type Concrete Pumping machine

A trailer-type concrete pump is a versatile, mobile pumping unit mounted on a towable chassis. It is designed for efficient concrete placement in various construction applications. This machine features a powerful hydraulic system that delivers concrete through pipelines at high pressure.

It is ideal for projects requiring long-distance or high-volume pumping. Different from the truck-mounted boom pumps, trailer pumps offer greater flexibility and lower costs. Thus, it is suitable for small to medium-sized projects, remote sites, or areas with limited access.

Especially, the compact design allows easy transportation between job sites. These pumps are widely used in building construction, bridges, tunnels, and agricultural applications. They provide reliable performance with lower operational costs compared to larger pump models.

Concrete boom pump truck

The concrete boom pump truck is multi functional construction machine, which can transport and place concrete at various heights and distances efficiently. It consists of a truck-mounted pump with a multi-section. The boom arm can extend up to 60 meters or more. Thus, you can use it in high-rise buildings, bridges, and large-scale projects for precise concrete placement.

The powerful hydraulic pump can push concrete through delivery pipes at controlled pressures. That also ensures smooth and continuous flow. You can remote control it for operating better. This may enhance safety and productivity by reducing manual labor and enable access to hard-to-reach areas.

Different working principles of concrete mixer machine and concrete pumps

The concrete mixers and pumps are used for different concrete processes. Their working principles are different, too. The concrete mixing equipment mainly utilizes the rotary drum or mixing blades to achieve proper homogenization.

And the pumping machines mainly use powerful hydraulic systems for pushing the liquid concrete through pipelines or hoses to the exact pouring locations.

Concrete mixer machine working principle

Daswell different types of concrete mixing equipment mix materials by different working principles.

The diesel drum mixer utilizes the rotary drum for mixing the materials evenly. There are internal blades, which lift and tumble the materials continuously when the drum rotates.

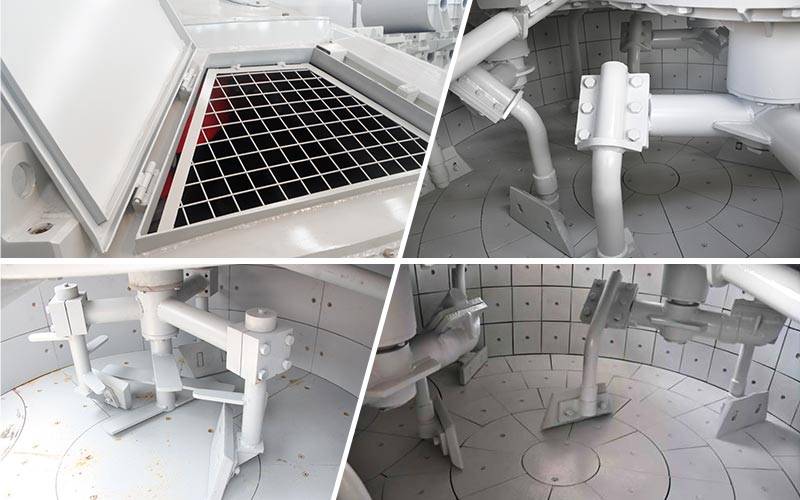

The twin shafts mixers employ counter-rotating shafts with mixing arms for faster, more efficient blending. There are two parallel mixing shafts. They rotates in opposite directions, creating an intensive blending action. Each shaft contains multiple mixing arms with specially designed blades. They will intermesh during rotation.

When the twin-shaft concrete mixing facility works, these blades perform three critical functions simultaneously: radial mixing (side-to-side), axial mixing (end-to-end), and vertical mixing (top-to-bottom). The counter-rotating motion generates high shear forces. It will break down material clusters. While the overlapping blade paths ensure no dead zones exist in the mixing chamber. This design produces a homogeneous mixture in just 30-45 seconds. It is significantly faster than single-shaft mixers.

The planetary mixers employ a unique orbital mixing pattern. There are multiple mixing stars, which rotate around their own axes. Meanwhile, they simultaneously revolvs around the central axis of the mixing bowl. This dual-motion system creates three-dimensional mixing coverage. It also ensures every particle contacts the mixing tools multiple times per cycle.

The rotating blades (typically 2-4 stars) move in an epicyclic path that constantly changes their position relative to the stationary bowl walls. That effectively scrapes the entire interior surface. For your reference, the vertical orientation and gravity-assisted mixing action make these units particularly effective for stiff concrete mixes and specialty mortars that require thorough paste development.

Different from the drum mixer machine, twin-shaft mixers and the planetary type mixing equipment, self-loading concrete mixer truck the the concrete mixer truck are multi functional. Especially, there mixing functions are different.

Self-loading concrete mixers integrate material handling, weighing, mixing and discharging functions into a single mobile unit. It collects raw materials using hydraulic shovel arms with buckets. Then transports them via conveyor belt or skip hoist to the mixing drum while automated weighing sensors ensure precise material proportions. And the rotating drum will rotates for mixing the materials.

The concrete mixer truck is mainly used for keeping concrete fresh when transporting. You can use it for transporting the mixed concrete from the concrete batching plant. It maintains concrete consistency through gentle 2-4 RPM drum rotation (agitation speed). Typically preserves the mixture for 60-90 minutes. This mixer truck is mainly used for transporting without concrete production function.

Concrete pump machine working principle

Daswell concrete pumps machine adopt hydraulic pressure system to transport liquid concrete through pipelines to precise placement locations. They utilize a dual-cylinder hydraulic system. It works in alternating cycles. While one cylinder draws concrete from the hopper, the other simultaneously pushes concrete into the discharge pipes.

We choose the S-valve. It automatically switches the flow direction between strokes to maintain continuous concrete flow. Whether for the boom pump truck, trailer concrete pump or the concrete mixer with pump machine, they all utilize the S-valve and hydraulic pressure system to pump.