Talc Powder Production Line

Talc Powder Production Line is widely used in building materials, chemicals, coatings, papermaking, and other industries, providing these industries with high-quality talc powder raw materials.

Introduction of the Talc powder grinding and processing production line

Talc powder production lines, also known as talcum industrial ultrafine grinding mills, primarily produce talc powder with a size of 150-2500 mesh.

Talc production lines offer stable operation, simple operation, and easy maintenance, ensuring reliable production capacity and high yield rates. They also effectively reduce operator training costs, simplify maintenance, and minimize downtime for repairs, making them popular with many users.

They also require no downtime for maintenance, operating 24/7.

Advantages of talc grinding production line

Stable Operation

Low Vibration, High Stability

The talc production line utilizes a vibration-proof foundation design to ensure smooth operation of the main machine. The ring roller mill is enclosed, and a negative pressure sealing system blocks dust backflow, ensuring continuous, stable production with zero dust emissions and excellent environmental performance.

Continuous 24/7 operation.

Centralized lubrication is used for key components, allowing for continuous lubrication of all lubrication systems without stopping the machine, effectively minimizing downtime and ensuring stable output.

Automated Diagnostic System

The entire talc grinding production line is connected to a PLC system. Online monitoring of indicators such as temperature, pressure, current, and dust concentration provides real-time warnings of operational anomalies.

User‑Friendly Operation

Touchscreen + PLC Integrated Control

The operating console features a touchscreen interface with a simple user interface. This system allows for easy viewing of system status, adjustment detail, and problem alarm logs, significantly reducing operator entry barriers and training costs.

Streamlined Operating Mode Switching

The system offers a variety of built-in operating mode templates for selection, with one-touch switching. Manual adjustments to parameters such as air speed, classifier speed, and feed rate are eliminated, significantly simplifying daily operations.

Easy Training

Operators can quickly master generation operations and simple troubleshooting.

Easy Maintenance

Modular Design for Maintenance

The high-speed transmission, classifier, fan, and motor are all modular and removable, allowing for easy maintenance without disrupting the entire line.

Non-stop inspection

The lubrication system can be maintained while it’s running, and peripheral components like the baler can be maintained independently without disrupting the main unit’s operation or production capacity.

Low-cost, fast-supply parts and spare parts are readily available.

Wear parts, such as wipers, are included as standard spare parts, making replacement and maintenance easy and quick to ship.

Remote Maintenance and Support

The equipment system is remotely connected to the Daswell platform, enabling remote monitoring and maintenance.

Talc powder production line process flow

Talc production lines generally process fine powder (20-400 mesh), ultrafine talc powder (400-1250 mesh), and micronized talc powder (1250-3000 mesh).

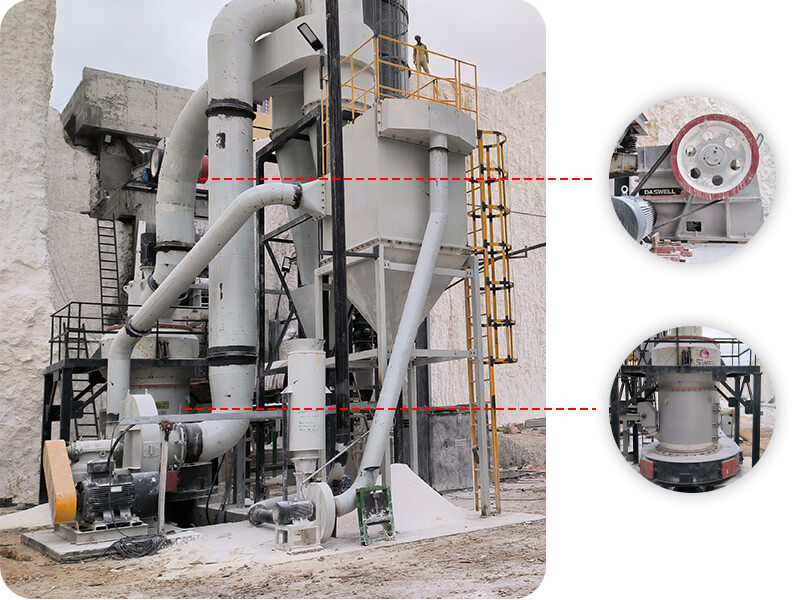

The talc production process consists of two main stages: crushing and grinding. The required equipment includes jaw crushers, vertical roller mills, classifiers, and powder collection systems.

Talc ore → Crushing (Jaw Crusher/Hammer Crusher) → Screening/Conveying → Grinding (Raymond/ball mill/vertical mill) → Classification (air flow or mechanical) – Recycling → Finished powder → Dust removal → Packaging

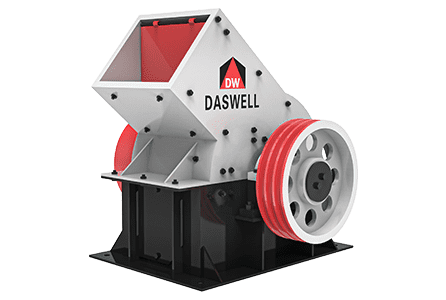

Stage 1: Crushing: Large talc ore is first crushed to a desired particle size (15mm-50mm) using a jaw crusher.

Stage 2: Grinding: The crushed talc flakes are transported by an elevator to a silo, where they are evenly and quantitatively fed into the grinding chamber of the mill via a vibrating feeder for grinding. Raymond mills and roller mills are available for fine powder production.

Grading and collection of finished powder

The finished product is then screened, and qualified dust is collected. A dust collector is used to isolate dust from escaping, ensuring a clean workshop and meeting environmental emission standards.

Advantages of Talc Powder Production Line

High Automation

- The daswell Talc Grinding Production Line utilizes a PLC and touchscreen control system, achieving automated coordination from feeding, crushing, grinding, grading, to packaging. This significantly reduces the impact of manual errors and improves talc powder production efficiency.

- The Talc powder grinding and processing production line supports remote monitoring of operating status (including temperature, current, output, etc.), remote control, and alarms, significantly improving the user experience and facilitating troubleshooting.

- The Talc Grinding Production Line’s automated process supports 24/7 continuous operation, offering excellent stability and high production capacity, making it particularly suitable for large-scale, continuous, and stable production of talc powder.

Low Cost & High Return

- Daswell independently undertakes the entire process of R&D, manufacturing, sales, installation, and after-sales maintenance. Without middlemen taking profit from price differences, the equipment is more cost-effective and the overall investment cost is significantly reduced.

- The Talc Powder Production Line’s modular design and efficient manufacturing process minimize resource waste, effectively lowering manufacturing and maintenance costs and shortening the project’s payback period.

High Efficiency & Productivity

- Daswell’s Talc Powder Production Line highly automated control and integrated process design offer simple and straightforward operation, enabling real-time adjustments to fineness and output to meet scale-up needs.

- Daswell’s Talc Powder Production Line ultrafine Raymond mill is twice as efficient as jet mills and stirred mills, enabling higher throughput and consistent fineness.

Superior Product Quality

- Engineered for stability and durability, our talc lines utilize high-quality components, including Siemens and Schneider controls, NSK/SKF bearings, alumina-ceramic coated classifiers, ASCO valves, and BWF dust bags. Together, these ensure consistent performance, reduced maintenance needs, and long service life—exceeding industry norms.

Environmentally Friendly & Safe

- Daswell’s Talc Powder Production Line highly automated control and integrated process design offer simple and straightforward operation, enabling real-time adjustments to fineness and output to meet scale-up needs.

- Daswell’s Talc Powder Production Line ultrafine Raymond mill is twice as efficient as jet mills and stirred mills, enabling higher throughput and consistent fineness.

Why choose the Daswell Talc Powder Production Line?

As an experienced Talc Powder Production Line supplier, Daswell has provided professional talc production solutions to numerous customers. To meet your talc powder production needs, Daswell can provide a complete production line featuring advanced technology, reliable performance, and customizable systems.

Global Reach and Trust

Founded in 1986, Daswell Machinery exports its products to over 80 countries, including the United States, Germany, Indonesia, the Philippines, Russia, Egypt, and Saudi Arabia. Daswell Machinery enjoys a strong reputation in powder processing, with products including silicate products like talc and quartz powder.

We have strategically located branches and local warehouses in the Philippines and Indonesia, ensuring fast overseas logistics, installation support, and local service.

Professional Team and Pre-sales Consultation

We have a highly skilled team of engineers and sales experts who work closely with customers to customize equipment configuration and processing procedures based on your material, desired fineness, and production capacity.

From initial consultation to complete production line design, each customer receives a fully customized solution based on 30 years of industry experience.

Professional Logistics and Delivery

Complete delivery process: In-house manufacturing, quality control, and direct shipment from the Daswell factory eliminate middleman markups and ensure competitive pricing.

Global logistics ensure complete delivery and minimize installation delays.

On-site Installation, Training, and Support

Experienced engineers will fly to your site to perform installation, commissioning, and training for your team, ensuring a smooth system startup.

Detailed training helps your operators quickly master the control system and streamlined maintenance procedures.

Fast after-sales service and quick on-site arrival

24/7 live chat, remote diagnostics, and a technical hotline ensure any issues are quickly resolved.

Troubleshooting: After-sales engineers arrive on-site quickly to ensure normal production operations are restored.

Excellent Performance and Customer Satisfaction

We have successfully delivered numerous projects in Africa, Southeast Asia, the Middle East, South America, and Europe, including designing talc production lines for global clients.

Customer feedback consistently highlights our professionalism, minimal downtime, shorter return on investment, and fast service.