Quartz Powder Processing Plant

Quartz is a kind of materials, whose Mohs hardness is 7. It typically appears colorless, translucent, or transparent. The raw quartz ore will be processed into small size quartz through primary and secondary crushing. Undergoing a further grinding process, it will become fine powder with Daswell quartz powder processing plant. That is high-purity quartz powder.

Because of its exceptional physical and chemical properties, the quartz powder has wide application across multiple industries. For example, you can use it for electronics, ceramics, glass, paints, and construction materials, etc.

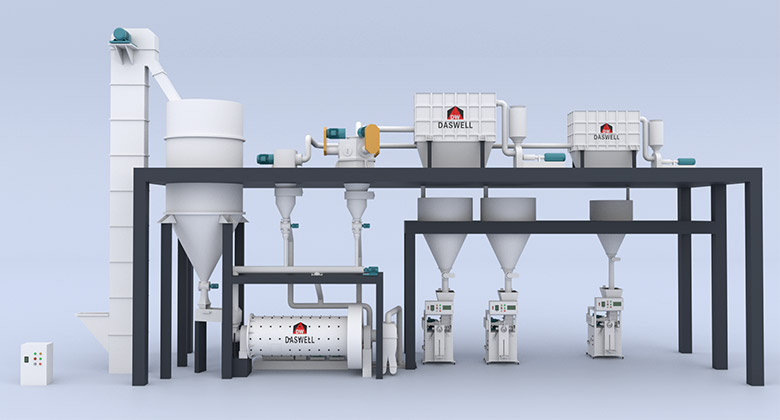

Daswell quartz powder processing plant is a production line, which is designed to process quartz stone into fine powder. Our quartz powder production line can transform raw quartz ore into fine powder through multiple stages. It has crushing, grinding, and classifying processes. Meanwhile, you can also re-grind the powders after classifying.

Advantages of Daswell quartz powder processing plant

In today’s competitive industrial landscapes, producing high-purity quartz powder efficiently is crucial for many industries. Whether for electronics, glass, ceramics, or construction, the quartz powder plays a key role. As an experienced powder grinding machinery supplier, Daswell has provided professional quartz powder production solutions for many customers.

Producing quartz powder is not simple as grinding the raw quartz. It needs crushing, grinding and classifying for making qualified quartz powder. While, there maybe some challenges for quartz powder producers. With Daswell quartz powder making machines, you can produce high quality quartz powder with low consumption and high efficiency.

- Stable product quality: The inconsistent particle size and purity will influence the finial applications. For example, in glass industry, ceramics producing, and the electronics industry, the quartz powder quality are important. Daswell quartz powder processing plant adopts PLC control system for operating and monitoring the powder production in real-time. It is convenient and simple for you to control the whole production process. Meanwhile, for adjusting the particle sizes, capacity, and classifying, the PLC control system can adjust them easily.

- Low energy consumption: Outdated grinding may waste electricity and raise operation costs. Daswell utilizes advanced technology for designing the machine, making sure high efficiency.

- Environmental friendly with less dust pollution: Poor dust control and frequent equipment wear will cause downtime and environmental problems. Daswell offers you dust collector for storing the finished quartz powders well, high decreasing the pollution.

- Simple production flow: Buying multiple machines from different supplier make the quartz powder production line inefficient and hard to control. Daswell integrated quartz powder making plant utilizes PLC systems for controlling easily. And we have complete equipment for every processes from crushing to collecting.

If you are looking for a high-purity, fine quartz powder processing plant, contact Daswell now. Daswell Machinery delivers advanced, efficient, and customized grinding solutions for you. We promise superior product quality and competitive production costs.

Daswell’s Integrated Quartz Powder Processing Plant Design for Efficiency and Stability

Generally, there are four stages of making the quartz into fine powder. They are preparation, crushing, grinding, and classifying processes. Daswell has integrated system for your quartz powder making. From the crushing to grinding and classifying, Daswell production line can realize it easily. Here you can learn these detailed processes and their functions better. It is helpful for you to establish your own quartz powder processing plant business.

Raw material preparation: The raw quartz ore materials are mined from quarries and carefully selected to remove the impurities. Then, washing these raw quartz, it can eliminate the dust and contaminants. This can ensure the quality of the final powder.

Crushing: After the drying and cleaning, you can send the quartz into jaw crushing machines for primary crushing. Our crushing machine can turn the materials into small size. And you can also use the hammer crusher or cone crushers for secondary crushing. These processes can reduce them to the required feed size for grinding.

Grinding: Our production line has a feeding machine for sending the crushed quartz into the grinding mill. For your reference, we also provide feed silos for storing the materials. Daswell has three kinds of grinding mills for you to choose. The ball mill grinding machine is the most popular equipment among our quartz powder making customers. According to your requirements, you can also choose our Raymond mill for your powder making.

Classifying: When the grinding process finishes, there is the classifying process. Daswell high-efficiency classifier will separate the quartz powder into qualified fine powder and coarse powder. The unqualified powder can be returned to the grinding mill facility for regrinding. The qualified fine powder will be collected in the product silos. There are dust collectors for collecting the powders, which avoid pollution and waste.

The whole quartz powder production line utilizes automated control system for full process monitoring and controlling. It ensures high efficiency, consistent quality, and minimal manual intervention. For your industries such as electronics, glass, and ceramics, this quartz powder processing plant is an ideal choice. There are various equipment configurations for you to choose. It is available to customize for you according to your own requirements. Just send an inquiry to Daswell, our technical engineer will design the most suitable solutions for you.

Why choose Daswell as quartz powder processing plant supplier?

How does Daswell Customize for your own quartz powder processing plant?

The efficiency and precision of the processing equipment will influence the quartz powder quality. Daswell advanced equipment for quartz powder processing plant utilizes delicate deisign. For your quartz powder production requirements, Daswell can offer you whole set production line with advanced technology, reliable performance, and customized systems. These machines can make sure the high purity, uniform particle size, and minimal contamination for your own project.

Crushing Machines For different stages

Jaw crusher is a widely used crushing machine in the mining process. It has high crushing efficiency. The raw quartz ore materials are big size. Using a jaw crusher for size reduction is an ideal choice.

For grinding use, the mill machine has strict requirements on the feeding size. Thus, you can choose the hammer crusher or cone crusher for secondary crushing. Both of them can reduce the quartz into smaller size. The feeding size for the grinding process should be under 30mm. The required size mainly depends on the grinding mill you use.

Grinding mills for Your Various Requirements on Finished Products

The ball mill machine is the most popular mill among all the grinding machines. Using this machine for quartz powder grinding, you should make sure the feeding size of crushed quartz is under 4mm. It can produce D97, 5-200 microns quartz powders. Daswell offers you various models with different capacities. You can contact us for getting your own ball mill machine.

Compared with ball mill grinding machine, the Raymond mill is mainly used for coarse powder production. If you want to produce 40-180 microns powder, this machine can meet your needs at an economic price. And the feeding size is 25-30mm, bigger than the ball mill machine. Besides, it is worth to mention that its high passing rate is difficult for other grinding mill equipment. It can achieve 99%.

| Feature | Ball Mill Machine | Raymond Mill Machine |

|---|---|---|

| Main Application | Fine and ultra-fine quartz powder production | Coarse and medium quartz powder production |

| Finished Powder Fineness (D97) | 5 – 200 microns | 40 – 180 microns |

| Feeding Size | ≤ 4 mm | ≤ 25–30 mm |

| Production Capacity | Wide range of models for small to large scale | Medium capacity, ideal for lower-cost operations |

| Passing Rate | Up to 98% | Up to 99% |

| Energy Consumption | Higher due to fine grinding process | Lower due to coarser output |

| Price Range | Higher investment, higher precision | More economical option |

| Best For | High-purity, ultra-fine quartz powder production lines | Cost-effective coarse quartz powder grinding |

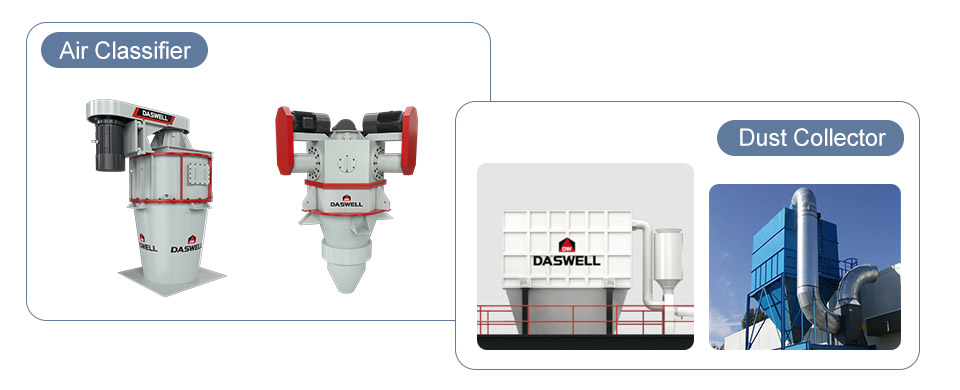

Air Classifier for Powder Quality Classifying

For separating the qualified quartz powder and unqualified powder, Daswell offers you air classifier. It utilizes air flow for selection. The air flow will carry the lighter fine powder upward. While the coarse ones will fall down because of the gravity. It is alternative for you to process the unqualified powder for regrinding. It is worth to mention that our air classifier is adjustable. You can adjust the air flow according to the powder size you need. We have PLC system for you to adjust it conveniently.

Environment-friendly Dust Collector

This mainly has two functions in the production line. Its primary function is collecting dust for reducing pollution. This is helpful for protecting the environment and providing a clean working condition. Meanwhile, Daswell designs a product silo for storing the finished quartz powder. Thus, the dust collector can not only reduce the pollution, but also collect the finished powder products.