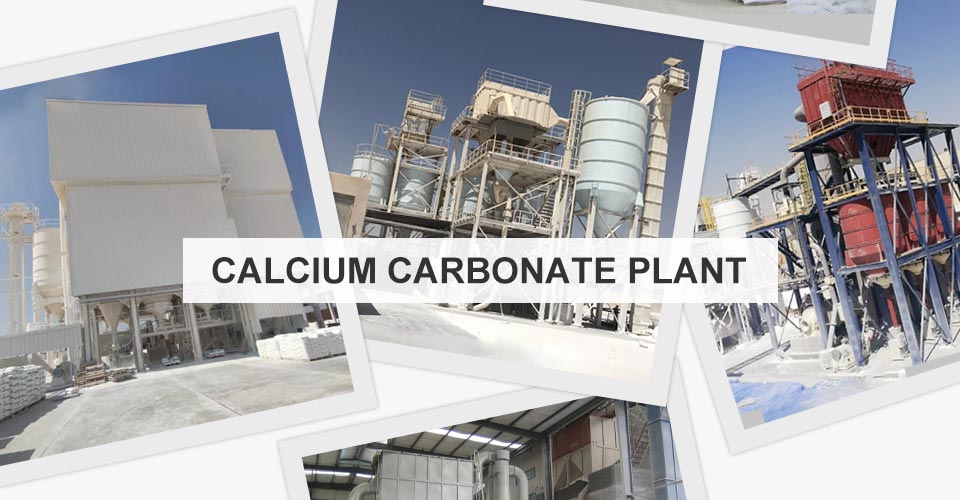

Calcium Carbonate Processing Plant

Calcium carbonate plant is also known as calcium carbonate processing or grinding plant. It is a production line where ground calcium carbonate powder are made mechanically in factories.

With versatile applications in many different industries, calcium carbonate powder, in this case, the ground calcium carbonate powder of various particle sizes is in great demand around the world. As the result, more and more shrewd businessmen want to build or expand their calcium carbonate powder processing plant all over the world.

What is calcium carbonate plant?

Calcium carbonate processing plant is a production line that obtaining ground calcium carbonate powder by grinding limestone or marble. Usually there are a complete set of machinery needed for the calcium carbonate production line.

And some calcium carbonate manufacturing plants are also equipped with calcium carbonate coating machine, so that both natural coated and uncoated calcium carbonate powder can be obtained.

There is no one-for-all solution for building a calcium carbonate production plant. For customers need to consider various requirements in powder fineness, production capacity and so on.

Calcium carbonate manufacturing process

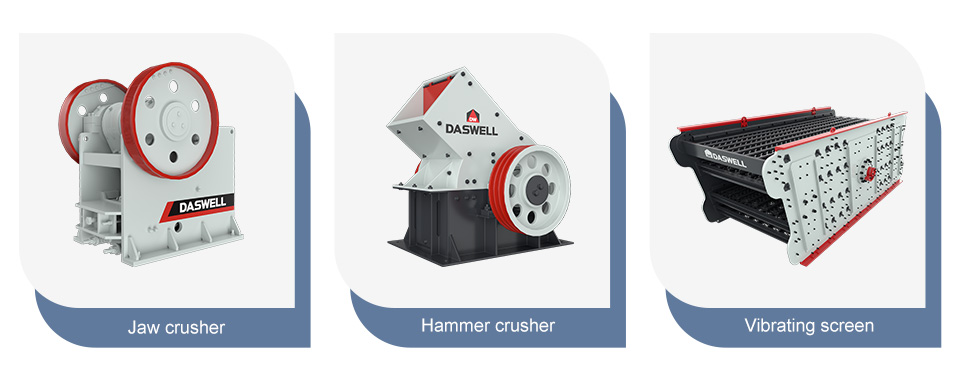

At first, the raw materials, such as limestone, calcite and marble are mined from the quarry. Then these raw material slumps are carefully selected, washed to ensure the high quality of finished calcium carbonate powder. And then these dried and cleaned raw materials will go through first and secondary crusher, such as jaw crusher and hammer crusher, to become the required feed sizes.

At this time, these materials are ready for further grinding. Firstly, the raw material is put into feed silo, from which raw material is transported to the ball mill through vibrating feeding device. In the ball mill, with the impact of media balls, these raw materials are ground to fine calcium carbonate powder.

And then the materials from the ball mill will be blown through classifier. The required fine ground calcium carbonate powder will be delivered to the product silo, while the coarser material will be returned to ball mill for regrinding. And the final product will be packed and stored for usage.

Of course, except the core machine such as grinding mill, classifier, there are also other transporting system, dust collector system, and packing systems. Besides, the whole calcium carbonate production process can be fully automatic and be controlled by operation panel.

Components of calcium carbonate plant

The calcium carbonate plant includes a complete set of calcium carbonate manufacturing equipment. For example, there are crusher, vibrating feeder, elevator bucket or belt conveyor, calcium carbonate grinding mill, air classifier, silos, dust collector, calcium carbonate coating machine, packing machines and so on.

Crushing machine

Quarried limestone is often too big to feed into calcium carbonate grinding mill. Besides, different calcium carbonate grinding mill have different feed material required sizes. So there is great need of primary and even secondary crushers. Usually, the jaw crusher is used to crush the basic materials such as limestone or marble. And there is also vibrating screen to screen the qualified sizes of feed material.

Grinding mill

Calcium carbonate grinding mill is the central equipment for calcium carbonate manufacturing plant. And there are many kinds of calcium carbonate grinders available, such as ball mill, roller mill, vertical mill, wet grinding mill and so on.

Since different grinding mills have different capacity and diameters, Daswell can help you to choose the best suitable one for your calcium carbonate grinding plant. And there are several factors to be considered, such as raw material property, desired fineness, production capacity and so on.

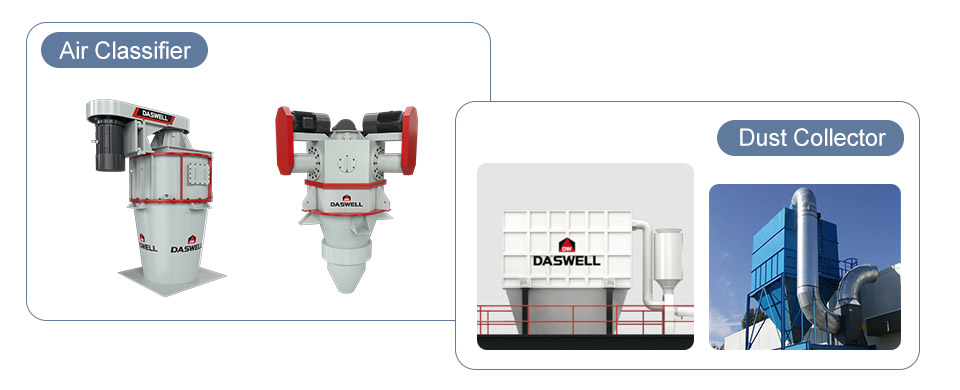

Air classifier

Calcium carbonate air classifier is used for further cut of calcium carbonate powder. After being ground in calcium carbonate grinding mill, the calcium carbonate powder will be transferred into air classifier.

In there, the air flow inside will carry the lighter powder upward and get further cut, while the coarse ones will fall down due to gravity. Calcium carbonate grinding mill and air classifier together can produce fine and ultra fine calcium carbonate powder.

Dust collector

To protect environment as well as the safety of employees, calcium carbonate grinding plant will be equipped with dust collector. Of course, Daswell offers several kinds of dust collectors to ensure the dust free working environment.

Coating machine

Calcium carbonate coating machine is used to coating calcium carbonate powder with stearic acid. And to obtain coated calcium carbonate, you can simply add a calcium carbonate surface treating machine to your calcium carbonate plant. As a result, your calcium carbonate grinding plant can both produce natural calcium carbonate powder as well as coated calcium carbonate powder, which make more economic value for you.

Powder packing machine

Daswell offers mainly two kind of calcium carbonate powder packing machine according to automatic style. One is semi automatic and the other is fully automatic. As the name implies the semi automatic calcium carbonate packing machine still needs human labor to finish the packing process.

While fully automatic calcium carbonate packing machine needs no more human labor and can pack and transfer bags of calcium carbonate powder to set area. Besides, there are also valve mouth packing machine and ton bag packing machines available.

Features of Daswell calcium carbonate plant

- Tailored turnkey solution. Daswell specializes in designing and engineering calcium carbonate processing line. And we also provide a complete set of equipment to meet customer’s needs in calcium carbonate powder fineness, production capacity, ground calcium carbonate applications and etc.

- Controlled calcium carbonate particle size. Daswell machinery company provides tailored solution for calcium carbonate grinding plant to meet customer’s various needs. The core part of calcium carbonate plant, the grinding mills of Daswell, whether ball mills with classifier or wet grinding mills, can produce ground calcium carbonate powder in various particle sizes from fine to ultra fine GCC powder.

- Various calcium carbonate powder production capacity available. According to customer’s needs, Daswell can offer you tailored solution with different calcium carbonate production capacity. A calcium carbonate production line can produce finished ground calcium carbonate powder in different particle sizes for different applications.

- Both dry grinding and wet grinding are available. Grinder or grinding mill is the core equipment for calcium carbonate grinding plant, which can largely determine the fineness of the end product. Daswell mainly provides ball mill combined with classifier and vertical wet mixing grinder.

- PLC control system. The PLC system can help you monitor the whole calcium carbonate production line and adjust the materials and so on.

- Automatic calcium carbonate production line available. Fully automatic calcium carbonate plant can ensure the efficiency as well as reduce the labor costs.

- A full set of machinery. Daswell supplies the complete set of equipment for the calcium carbonate plant, from crushing machine, transporting system to grinding mill, classifier, packing machine as well as optional coating machine.

- High quality final product. With high quality raw materials, Daswell can provide quality tailored system that produce uniform ground calcium carbonate with high brightness, large surface area, high stability and required fineness. Final ground calcium carbonate powder can be used in paper, plastic, paint and other industries.

- Environmental consideration. As for the dust produced from the calcium carbonate manufacturing process, Daswell supplies de-dusting and other equipment.

What is calcium carbonate?

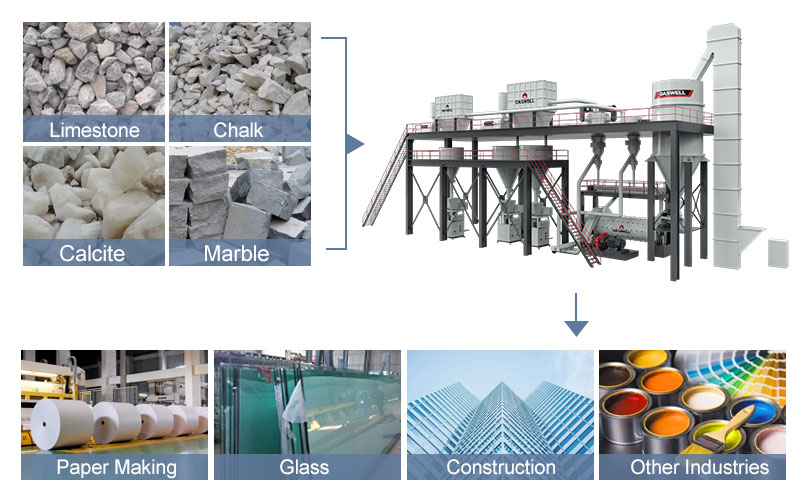

Calcium carbonate(CaCO₃) is a chemical compound widely found in natural inorganic compound such as limestone, chalk, calcite and marble. Due to its special properties, such as white color, calcium carbonate powder are widely used in various industries as fillers or coating pigment.

What’s more, calcium carbonate can generate quicklime though heating, while quicklime can react with water to produce hydrated lime. All these three materials have wide range of applications in paper, glass, construction and other industries. So it is of great economic value to build a calcium carbonate processing plant.

However, the calcium carbonate manufacturing plant consists of a complete set of machinery which need professional design and engineering. Daswell Group Co., Ltd is the preferred partner for you with rich experience in calcium carbonate plant project designing and engineering. Besides, Daswell offers complete set quality equipment relevant to the ground calcium carbonate plant.

Application of calcium carbonate powder

Due to its special properties, ground calcium carbonate powder can be used in many areas. For example, the calcium carbonate powder are usually applied in paper, construction, paint, plastic, glass and other industries as filler, adhesives and so on. For instance, in paper industry, calcium carbonate is often used as an inexpensive filler to brighten opaque paper, due to its high brightness and light scattering characteristics.

Of course, different usages have different requirement for the finished calcium carbonate powder, while high quality calcium carbonate with great whiteness have greater economic value. And there are several factors that can affect the quality, fineness, whiteness and surface of the calcium carbonate powder.

One is the quality and properties of raw materials to be processed. Another important factor is the grinding system, wet or dry grinding mill, which can have an impact on the whiteness and fineness of the end product. In line with your needs, Daswell will provide tailored turnkey solutions for your calcium carbonate manufacturing process with consideration of costs.

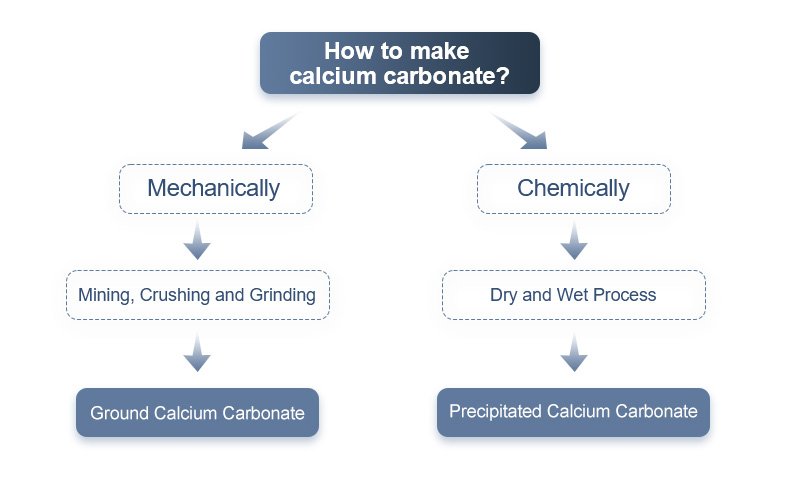

How to make calcium carbonate?

It is known that there are two ways to produce calcium carbonate.

Mechanically, calcium carbonate powder is obtained from its various raw materials by mining, crushing and grinding. Then it is classified to required sizes. So this kind of calcium carbonate is called ground calcium carbonate.

Besides, there are two ways to produce ground calcium carbonate: dry and wet process. Chemically, calcium carbonate is prepared with several chemical changes.

Firstly, add water to quicklime(CaO) to produce calcium hydroxide(Ca(OH)2). And then the calcium hydroxide react with carbon dioxide to precipitate the calcium carbonate, and so the end product is called precipitated calcium carbonate.

If you want to get more information abut calcium carbonate processing plant, welcome to contact us. Our team will provide you with professional suggesstion!