Calcium Carbonate Coating Machine

Calcium carbonate powder surface coating machine is used to modify the surface of ground calcium carbonate powder. As a result, the property of the ground calcium carbonate powder will be changed. And with unique characteristics, coated calcium carbonate powder can be applied in wide range areas.

Usually the machine is added to existing carbonate plant to produce both coated and normal types of calcium carbonate powder. Of course, you can build a new ground calcium carbonate production line with calcium carbonate coating machine.

Process for coating calcium carbonate

The calcium carbonate coating plant is often work side by side with calcium carbonate plant. For the coated calcium carbonate can add vaule of natural calcium carbonate powder produced by your calcium carbonate plant. Here the detailed explanation of the process for coating calcium carbonate powder.

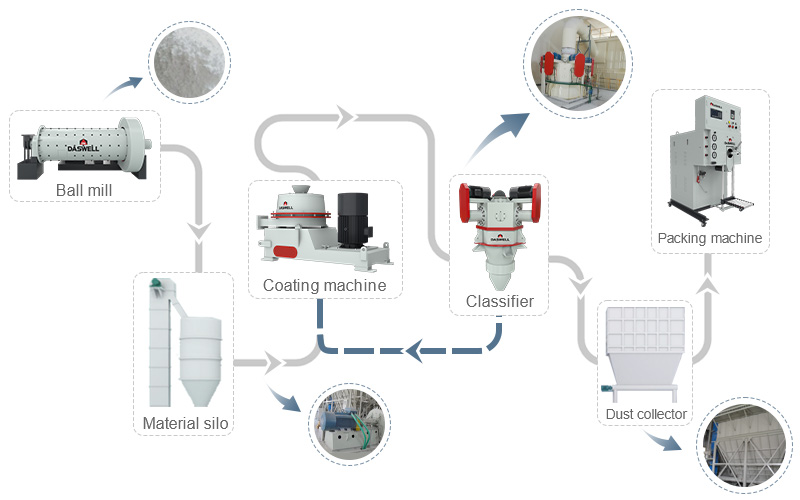

Firstly, the calcium carbonate powder from ball mill is transferred to the material silo by bucket elevator. Then controlled amount of GCC powder and stearic acid is mixed in screw mixer. And the blower will blow the mixture into the calcium carbonate coating machine.

Since the coating machine is equipped with high speed vortex, the mixture in the coating machine will be blend and pulverized so that the coating can be uniform.

Then with the flow of air, the mixture will go into classifier, in which the coated calcium carbonate is further cut in sizes. The desired coated calcium carbonate will go to product silo after going through the dust collector. While the coarse coated calcium carbonate will be rejected and go into the coating machine again for anther round of coating process.

As a result, Daswell calcium carbonate coating plant can produce controlled sizes of coated calcium carbonate with high whiteness and consistency.

Different types of powder coating machine

About the types of mineral powder coating machine, our Daswell Machinery company provide our clients with different choices, like vortex mill coating mill, three roller coating machine, high-speed mixing coating machine, etc.

The vortex mill coating machine adopts conical rotor and stator, by adjusting the clearance of rotor and stator to control the fineness and output. Its powerful eddy current flow field makes the material instantaneous crushing, so the material stays in the cavity for a short time, without temperature rise.

Nowadays, the new type vortex mill coating machine with classifier is the most advanced coating solution for calcium carbonate in China.

Three-roller coating machine can change the action of cyclone vortex through the relative movement of three rotors to realize the coating of powder surface. Because it can achieve self-friction heat generation, it does not need a heating device, which can save your investment cost.

The high-speed mixing coating machine is suitable for the modification of materials with high modification temperature and long reaction time by silane and other additives.

Features of calcium carbonate coating equipment

- High coating rate. Daswell calcium carbonate surface modification machine can form a closed circuit with the air classifier. In the air classifier, large granule coated calcium carbonate will be returned to the coating machine for further coating. As a result, the finished coated calcium carbonate powder is of high coating rate.

- Great economic value. To add calcium carbonate surface coating machine to your calcium carbonate plant, you can produce both coated and natural ground calcium carbonate powder. Due its wide application, you can use or sell these end product for different industries.

- High capacity with low energy consumption. Daswell calcium carbonate powder surface coating machine has low installed power rating. And since it work with air classifier in a thermal closed circuit, the calcium carbonate coating system can save costs.

- High efficiency. Daswell calcium carbonate modification machine needs few stearic acid additives, but can produce quality coated powder calcium carbonate with high coating rate.

- High quality coated calcium carbonate powder. The finished coated ground calcium carbonate powder made is of high quality in consistency, with better dispersion, low moisture content and better impact strength.

- Environmental friendly. Daswell calcium carbonate coating machine works in negative pressure so there is little dust in the production line.

- Automatically control. The coating system for calcium carbonate powder in Daswell are fully controlled by computer, so you can monitor and adjust the production line according to your needs easily.

Choose a right modified powder machine

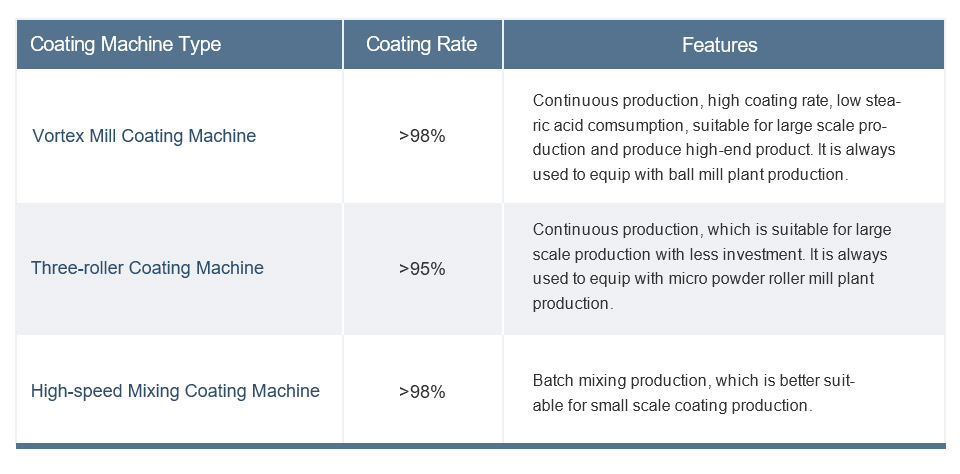

There are various of powder coating manufacturing machine for your selection. So you need to compare these different machines to pick out a suitable one. Here is a chart to give you a quick overview of their respective advantages.

The vortex mill coating machine and three-roller coating machine can achieve the continuous modification. While the high-speed mixing coating machine is modified in batches.

In addition, their coating rates are different. The coating rate of vortex mill coating machine can reach 98%, and the high-speed mixing coating machine is the same. At the same time, the coating rate of three-roller coating machine can reach 95%.

On the other hand, they have different capacity. You need a rough estimate of how many finished products you need per hour or per day.

If you don’t know much about powder surface grinding coating modification machine, you can send message to us. We can provide you with our coating machine brochure and our engineers also can solve your problems.

What is coated calcium carbonate?

According to Wikipedia, powder coating is a type of coating that is applied as a free-flowing, dry powder. More specifically, powder coating is to apply additives to fine powder in order to improve product handling and performance.

In the case of calcium carbonate coating, it means to add stearic acid to fine or ultra fine calcium carbonate powder, so that the surface properties of GCC powder can be changed. Initially, the ground calcium carbonate powder is hydrophilic, which can be unfriendly to organics like polymers.

However, the plastic industry is also in urgent needs of cheap white filler. If ground calcium carbonate powder is added to plastics, a lot of frictions can occur due to the high surface energy of GCC powder particle. Yet when the surface of GCC powder is modified with steraic acid, the coated calcium carbonate powder become hydrophobic and can reduce the friction when added to plastics.

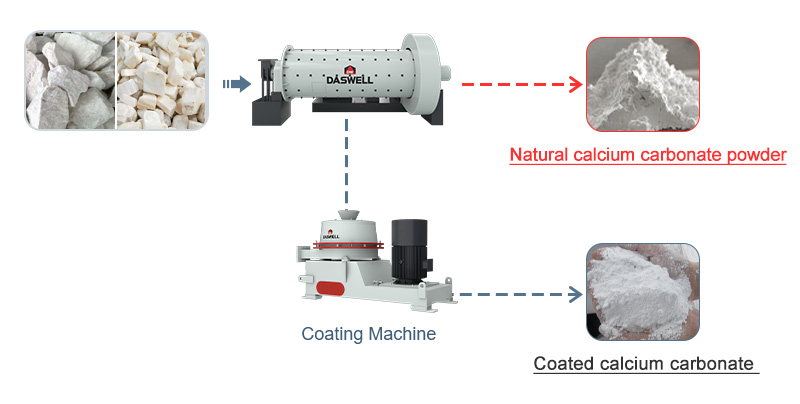

Differences between coated calcium carbonate and natural calcium carbonate powder

Natural calcium carbonate powder is often obtained by grinding calcium carbonate rich rocks such as limestone or marble. Coated calcium carbonate is to modify the surface of calcium carbonate powder with various acid, in which stearic acid is often used.

Coated calcium carbonate is widely used as white filler in various products, notably plastic pipes. The stearic acid coating enhances the mixing and binding with the plastic and can also served as smoothing and lubricating agent that reduce wear. In this way, it can be said that coated calcium carbonate is value added version of natural calcium carbonate powder.

Coated calcium carbonate uses

As stearic acid coated calcium carbonate is hydrophobic, it is more friendly to organics like polymers than ground calcium carbonate powder. As a result, coated ground calcium carbonate powder can be used as filler in plastics for PVC, rubber, decorative paints, slippers, textile and other similar industries.

Ground calcium carbonate coating machine in Daswell can produce quality coated calcium carbonate powder with high coating rate, high consistency, controlled particle sizes, and great brightness. As a result, produced coated calcium carbonate can applied in various industries with high economic value.

As a professional mineral processing machinery, our Daswell Machinery has accumulated over 30 years experience. If you have any demand, welcome to leave your message to us!