Production Requirements & Product Configuration

Customer production requirements:

Customers are mainly used to produce D97, 6-25 microns ground calcium powder, of which D97, 10 microns powder output needs to reach 2.8t/h.

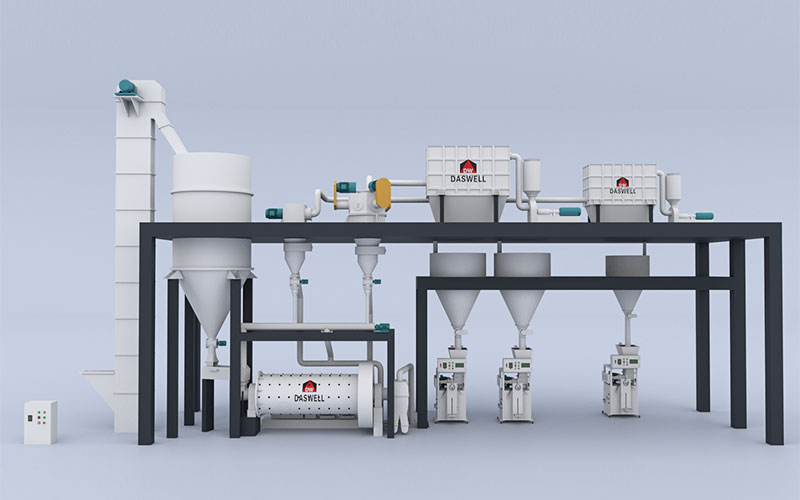

Product configuration and model:

The main machines of the ball mill production line we configure for customers include bucket elevator, Φ2.2*5.5M ball mill, AMS8005 classifier, XMC70-7 pulse bag dust collector, fan, packaging machine, UCOAT1000 coating machine and other parts.

Product Features

- Our ground calcium grinding and grading technology, equipment and control level belong to the world’s advanced level. The powder produced is basically the same quality as the calcium carbonate produced by OMIYA company as determined by Malvern laser particle size analyzer.

- The grader cuts the particle size accurately, easily grades -5μm ultra-fine products, and obtains high-definition micro powders.

- The fine powder content of the product is high, the particle shape is uniform, and the product particle size control is flexible.

- The automatic control system can realize chain control to ensure stable and adjustable feeding.

- High grinding efficiency and stable product performance.

- The calcium carbonate production line is equipped with precision instruments to ensure accurate recording and efficient and stable production.

- The dust emission is the lowest and the environmental pollution is extremely small.

- The ball mill production line has good running stability, simple operation control and easy maintenance.

- The ball mill production lines can be custom designed to ensure customer satisfaction in every detail.

Customer Introduction & User Evaluation

This customer learned that our ultra-fine ground calcium ball milling equipment is easy to use, has high output, and accurately cuts the particle size of the product powder through the introduction of our old customer. And the customer visited our old customer’s local equipment work site in Egypt and learned that our ball mill production line is still running well after a few years of operation. After comparing with many manufacturers, he felt that our ground calcium grinding and grading technology, equipment and control level are all of the world’s advanced level, and it is especially suitable for the production of D97, 5-45 microns powder. So, he decided to buy a ball mill classification production line of the same size from our company. This production line was installed and commissioned in 2019.

We provide customers with 24 hours online service. In the production process, once there is a problem with the equipment, the customer can feedback at any time to solve it. Since the customer is very satisfied with our service and equipment quality, he ordered a ground calcium production line from our company one year later and has been put into use. Due to the good production performance of the equipment and the high return on investment, the customer suggested to his friend to purchase a ball mill production line, which is currently being installed and debugged.

In our daily communication with customers, we learned that customers are very satisfied with our company’s ball milling production line in the following points: low energy consumption, high output, accurate particle size of finished products, high modification rate of modification equipment, and low consumption of stearic acid.

Customers not only highly recognize our Daswell company’s equipment quality and service, but also actively recommend our equipment to peers and friends.