Barite Powder Processing Plant

Barite is a kind of high-density, chemically inert mineral. It is primarily used in drilling fluids, industrial fillers, coatings, and chemical processes. Due to its unique properties, barite powder is crucial in oil drilling. It is helpful for controlling well pressure. And for the production of paints, rubbers, and plastics, it also plays key roles.

How to choose a suitable barite powder grinding solution?

For various applications, the raw barite ore should be processed into fine, high-quality powder. The powder typically ranges from 75 to 600 mesh. The high-whiteness products has higher requirements on the impurities. Therefore, it is essential for you to choose a stable, efficient, and reliable barite powder grinding production line. The plant should ensure consistent particle size distribution, low contamination, and high production capacity.

Daswell is professional for offering comprehensive solutions with rich experiences. We can provide barite powder making solution from crushing, grinding, classifying to packing. Especially, our custom-designed plants are particularly popular in regions like Egypt. They are satisfied with the reliable performance and quick setup. Many customers choose Daswell for new production lines and capacity expansions.

Why choose Daswell for barite powder grinding solutions?

Customized solutions for your need

Daswell has rich experience on designing and manufacturing mineral processing equipment. For your barite powder grinding requirements, we provide tailored solutions to meet your specific needs.

From plant design to equipment configurations and final commissioning, Daswell engineers will customize a barite grinding plant for your own requirements. We make sure that our solution can meet your production capacity, target fineness, and environmental standards.

Energy-efficient equipment and reliable performance

Our barite grinding equipment are designed for energy efficiency. They help you to lower the operational costs. Our systems, including Raymond mills, ball mills, and the ring roller mills, all of them can provide consistent output with minimal energy consumption.

The grinding machines are durable and you do not need to maintain them frequently. We choose branded Siemens motors and SKF bearings for manufacturing machines. These advantages makes Daswell a ideal choice for your business.

Especially, for the high-whiteness of barite powder requirements, Daswell offers you ceramic-lined grinding mills. It can only prevent iron contamination, but also protects powder whiteness. If you are looking for low-maintenance with high-performance grinding solution, contact Daswell.

Professional after-sale service

Daswell’s engineering team provides full on-site support for you. We ensure your barite grinding plant are well delivered, installed and optimized on time. Especially, we have office in Indonesia, Philippines, and Egypt. We have helped our customer in Egypt for powder grinding plant installation and operation. Daswell offers you installation guidance, equipment testing, performance adjustment, and operator training. Most of the powder processing projects installation can be completed within one month.

Besides, we also offer remote support, spare parts supply, maintenance consulting, and upgrade recommendations. Our comprehensive after-sales system is one of our great advantages.

What is customized barite powder grinding solution?

Designing an efficient barite powder production plant solution is not just selecting a grinding mill machine. According to your different raw materials, final powder fineness, production capacity, installation conditions, and local environmental requirements, Daswell will design a special grinding plant for you. We provide a full set of customized engineering services to ensure your barite grinding plant runs well.

Whether you need fine powder or ultra-fine barite powder, we can offer you customized grinding and classifying systems. What’s more, it is available for you to choose the ceramic-lined barite grinding mill for making sure the high purity and whiteness of barite powder.

Every plant is designed for stable output, low energy consumption, and long service life. We make sure the best ROI for your business. We have installed mill plant solutions for processing calcium carbonate powder, talc powder making, and quartz powder grinding.

How does Daswell customize for your barite powder grinding solution?

Raw materials analysis and crushing system design

According to the hardness, moisture, impurity level, and the required feed size for the barite mill. Considering the big size of raw barite lumps, Daswell can configure suitable crushers for your primary and secondary crushing.

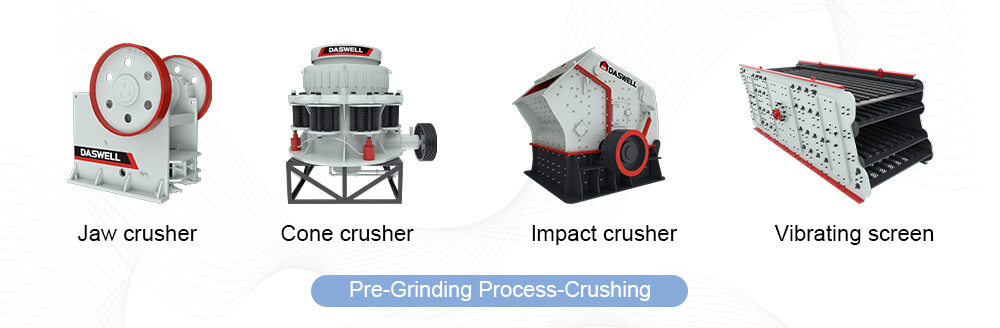

Generally, the crushing system includes a jaw crusher, impact crusher or hammer crusher, and the vibrating screen.

This crushing system makes sure that only the qualified material can enter the grinding machine. It improves grinding efficiency and lowers energy cost.

Selecting the right barite grinding mill

The grinding mill is the core equipment for the barite powder processing. Daswell offers ball mill machine, Raymond mill, and the ring roller mill with a classifier system.

Meanwhile, for some industries such as coatings, chemicals, and fillers, there may be some high requirements on the barite powder whiteness. Daswell offers grinding mills, which is equipped with ceramic liners and ceramic grinding media.

This design can prevent iron contamination, protect whiteness and purity of barite powder. It is important for coatings, plastics, and chemical applications.

High-precision classification for stable fineness

For your projects, which require fine or ultra-fine powder, Daswell integrates a high-performance air classifier. This machine has adjustable rotor speed and controlled airflow. With this machine, you can separate the fine powder from coarse particles. It makes sure the consistent powder size from 75 microns to 5 microns.

Daswell optimized match between the mill machine and the classifier improves output. At the same time, the energy usages lowers with uniform product stability.

Dust collection and environmental protection

Daswell also configure a high-efficiency dust collector system for the barite powder grinding solution. It meets modern environmental standards.

Our dust collectors ensure clean and safe operation during the crushing, grinding, conveying, and packing processes. This guarantees compliance with environmental regulations. And it also improves the plant’s working environment.

Automated packing system for finished barite powder

There are semi-automatic and fully automatic packing machines for 25kg, 50kg, and ton-bag packing. The semi-automatic powder bagging machine still needs a worker for packing. Choosing the fully automatic packing machine, it can finish the whole packing process automatically without workers.

With our integrated conveyors and sealing systems, the packaging speed will be highly improved. It also reduces your labor costs.

According to your specific requirements on the production capacity, goals, and your budget, we will design the most suitable barite powder making plant for you. Just send an inquiry to us now, getting your own barite powder grinding solution.