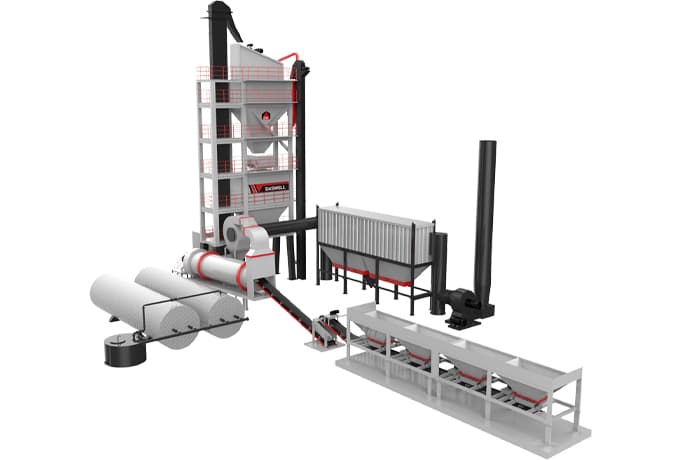

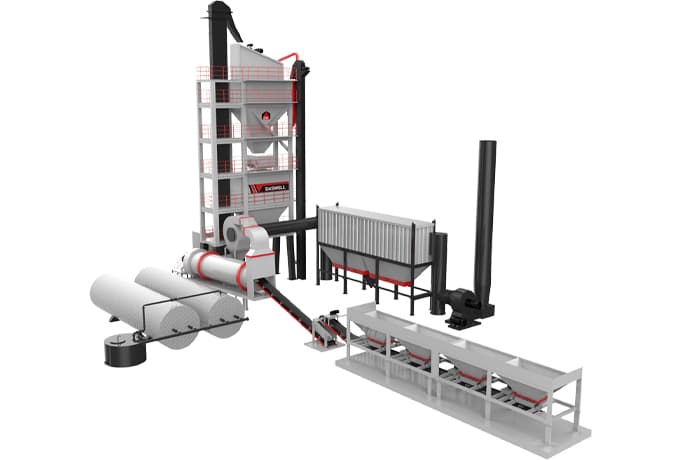

Stationary Asphalt Mixing Plant

Stationary asphalt mixing plant is a kind of mixing equipment that heats aggregate and bitumen to a certain temperature according to a certain ratio and is used to produce a black mixture suitable for laying asphalt pavement.

Description

Stationary asphalt mixing plant is suitable for large scale urban road construction projects with high quality requirements and is a complete set of equipment for mass production of asphalt mixture. All the work processes of the stationary asphalt mixing plant are precisely designed to ensure that the processes of feeding, drying, heating, weighing, screening and mixing are excellently completed under the action of the control system.

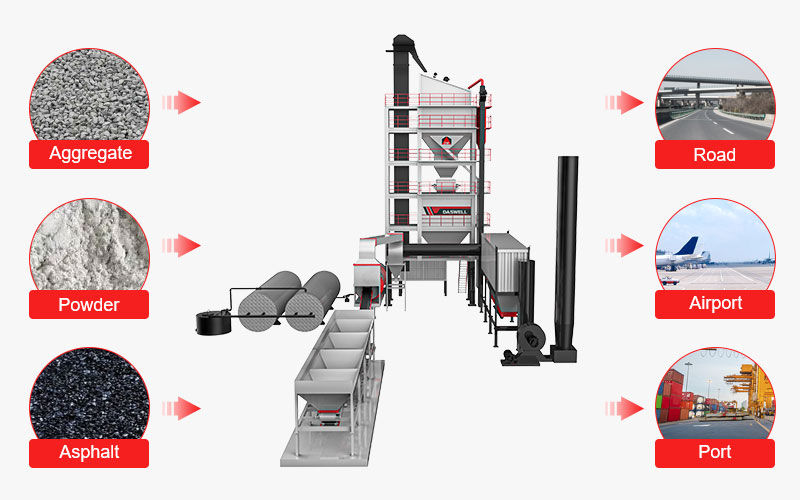

Raw materials: aggregate, powder, bitumen

Applications: highways, city roads, airports, ports, squares, town construction, etc.

Stationary asphalt plant work process

The working principle of stationary asphalt mixing plant is to convey, weigh, mix and discharge the three raw materials: aggregate, asphalt and mineral powder. In order to ensure the quality of the finished product, the operator should strictly follow the operating instructions of the stationary asphalt mixing plant.

Advantages of stationary asphalt mixing plant

- The drying drum of this asphalt station uses high quality burner. Through computer control, it can realize the synchronous regulation of gas and air to ensure the efficient use of heat energy, and also effectively protect the ecological environment.

- The screen box of the vibrating screen and the bin wall of the hot aggregate bin are equipped with slag wool insulation layer, which can effectively prevent heat dissipation.

- This dust removal system consists of a primary volute casing collector and a secondary bag dust collector, which can efficiently purify dusty exhaust gases under continuous loading.

- The stationary mixing plant is also equipped with a perfect computer control system, with precise control, flexible operation, automatic recording, printing and tabulation, recipe storage and protection and other functions.

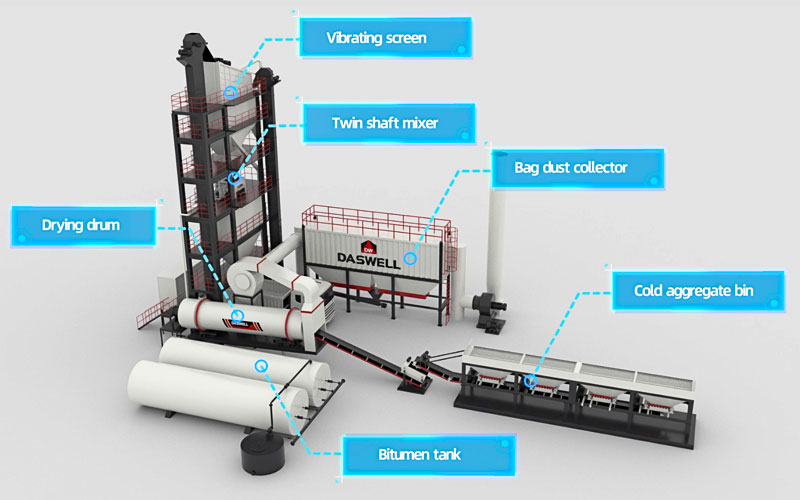

Main components

Stationary asphalt plant mainly consists of cold aggregate supply system, drying drum, combustion system, hot aggregate elevator, vibrating screening system, hot aggregate storage bin, weighing system, mixer machine, powder supply system, raw asphalt supply system, heat conduction oil heating system, dust removal system, finished product bin, electrical control system, air control system. The quality of all components will not only affect the quality of the finished asphalt, but also have an impact on the environment, so every detail of the production process is crucial.

How to choose suitable stationary asphalt plant?

When choosing a stationary asphalt plant, the highest capacity and highest configuration asphalt plant is not always the best; only the one that meets your needs is the best. There are many factors to consider when choosing an asphalt plant, including project requirements, purchasing budget, capacity, model, configuration, etc. So in order to purchase a right stationary asphalt plant and ensure that you get the best value for every dollar you invest, you need to consider the following:

- Production capacity requirements. Based on the size of the project, calculate the output of finished asphalt required per hour for the project.

- What is your project? City roads or airport roads?

- What is the thickness of road asphalt?

- Fuel type. The fuel for the combustion system can be natural gas, coal, diesel. What kind of fuel do you use?

- What type of dust collector do you need? Or let us know your local environmental standards.

- What is your purchasing budget?

- Based on the above information, we will select the model and provide you with a quotation. If you are planning to purchase asphalt plant, come and contact us!

Why choose Daswell?

Choosing a reliable manufacturer of stationary asphalt mixing plants is essential to reduce the operation and maintenance costs of the plant and to get the maximum return on investment. So what advantages does Daswell offer?

- Daswell has focused on manufacturing asphalt plant for more than 30 years and has rich experience.

- We offer many types of asphalt plants to meet the different needs of our customers, including stationary plants, mobile plants, batch mix plants, drum mix plants, etc.

- We use high quality accessories to ensure the quality of stationary asphalt mixing plant and extend the life of our products.

- We have experienced engineers who can provide customized design solutions for our customers.

- We provide perfect after-sales service to ensure your equipment to carry out stable production. In case you encounter any problem, we will solve it for you in time.

After-sales service

We can help our customers design the most appropriate solution, including site planning, schematic drawings, etc., to maximize the productivity and return on investment of the asphalt plant.

We provide a full range of after-sales service, including installation and commissioning, staff training and guidance, spare parts service, maintenance, one-year free warranty, etc.

We can provide you with high quality stationary asphalt mixing plants. There is always a specification for you. Please contact us today for more details.

All the staff of Daswell will do their best to provide every customer with the best quality products and the most perfect service, and we look forward to long-term cooperation with you.

Technical Data:

| Model | SAP700 | SAP1000 | SAP1200 | SAP1500 | SAP2000 | SAP2500 | SAP3000 | SAP4000 | SAP5000 | |

| Productivity (t/h) | 60 | 80 | 100 | 120 | 160 | 200 | 240 | 300 | 400 | |

| Mixer capacity (kg) | 750 | 1000 | 1200 | 1500 | 2000 | 2500 | 3000 | 4000 | 5000 | |

| Fuel consumption (standard condition) | Oil (kg/t) | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 | 5.5-7 |

| Fuel(kg/t) | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | 10 | |

| Measurement accuracy | Aggregate: ±0.5%Powder: ±0.5%Bitumen: ±0.25% | |||||||||