100-ton cement silo successfully sold to Manila, Philippines

Project Background

Manila, the capital of the Philippines, has seen rapid development in its infrastructure and real estate sectors in recent years, leading to a continued increase in demand for concrete. The client, a local construction contractor, primarily undertakes large-scale residential buildings and municipal road projects. To ensure continuous concrete production across these projects, the client decided to purchase a 100-ton cement silo to improve raw material storage and production efficiency.

After comparing several suppliers, the client ultimately selected the bolted cement silo solution provided by Daswell Machinery.

Project difficulties and challenges

1.Large transport volume: A 100-ton cement silo is enormous. Shipping the entire silo would result in high freight costs and inconvenience.

2.Limited on-site space: The client’s construction site is located in downtown Manila, and the warehouse installation area is relatively small, necessitating higher requirements for lifting and assembly.

3.Tight deadline: The client’s project was under tight deadline, and they wanted the cement silo to arrive and be operational as soon as possible.

Our Solution

1.Bolted Design, Optimized Transportation

We recommend bolted cement silos, which can be disassembled into standard modules for shipping. This significantly reduces ocean freight costs and facilitates quick installation on-site in the Philippines.

2.Customized Packing Solutions

We optimize container utilization based on your booking schedule, ensuring every component fits optimally, saving costs and ensuring safe transportation.

3.Installation and Commissioning Services

Upon arrival, we dispatch experienced engineers to the Manila site to assist with the installation, commissioning, and operator training of the cement silo, ensuring smooth commissioning.

How the client found us

This client initially found our official website by searching Google for “cement silo for sale in the Philippines.” After browsing our project examples and customer reviews, they contacted us through our website form.

Why Choose Daswell?

Extensive Industry Experience: We have a strong reputation for successful cement silo projects in the Philippines.

Price-Quality Balance: Daswell’s 100-ton cement silo offers the best value among similar products.

Full-Service: From selection, transportation, installation, and maintenance, we provide one-stop services, not just equipment sales.

After-Sales Support: Our local service team is ready to provide technical support to customers at any time.

Advantages of the Daswell Cement Silo

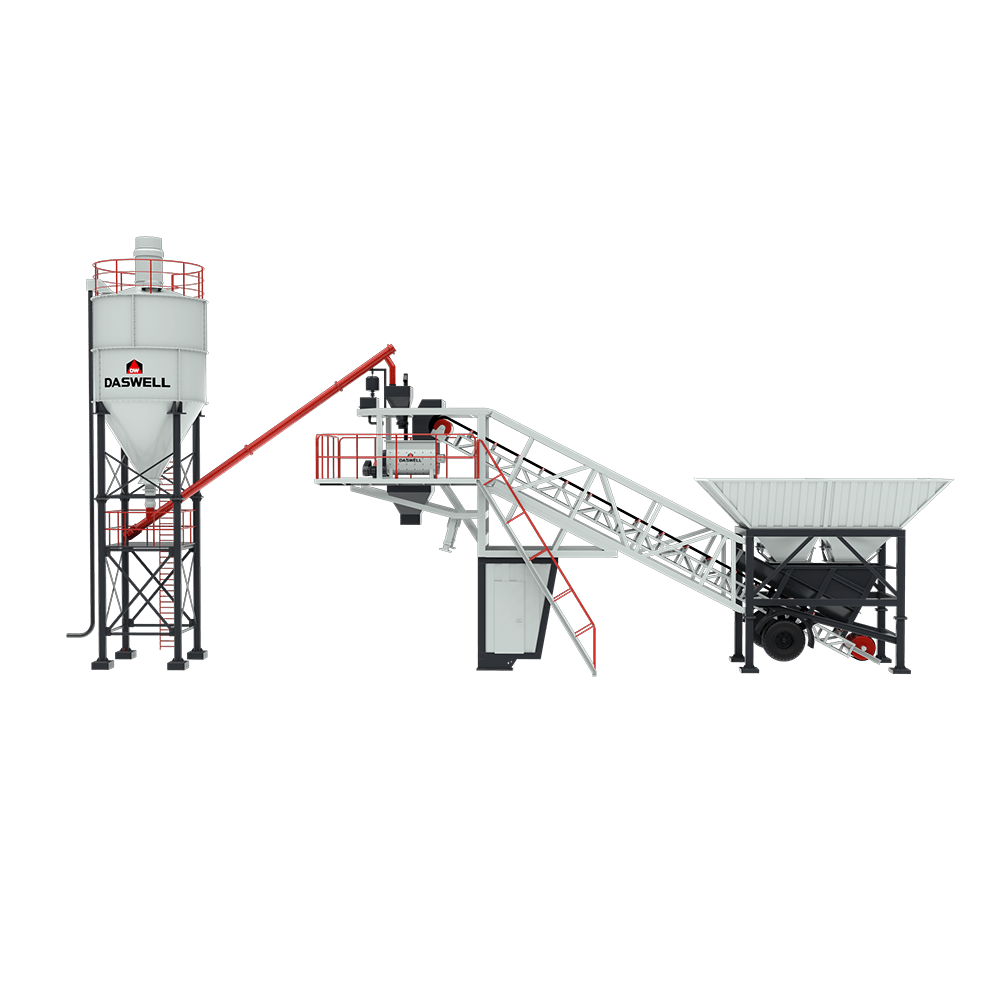

Compared to standard cement silos on the market, the Daswell 100-ton bolted cement silo offers the following features:

Made of high-strength steel, it is durable and suitable for the Philippines’ humid and typhoon-prone climate.

The standardized modular design allows for flexible transportation and installation.

Comes with a complete set of accessories, it can be directly used to store bulk materials such as cement, fly ash, and mineral powder.

It is dust-proof and environmentally friendly, reducing on-site dust pollution.

Packing Plan and Packing List

To reduce transportation costs, we disassembled the entire 100-ton cement silo and packed it into a 40HQ container. The main items are as follows:

Several silo steel plate modules

Legs and ladder assembly

Top guardrail and safety valve

Discharge port and butterfly valve

Dust collector and arch breaker

Auger conveyor

Bolts and seals

100-ton cement silo configuration list

Silo diameter: 3260 mm

Total height: 16,450 mm

Storage capacity: 100 tons of cement/powder

Discharge method: Pneumatic butterfly valve + screw conveyor

Dust removal system: High-efficiency roof dust collector

Arch breaker: Pneumatic arch breaker to prevent material bridging

Safety devices: Pressure valve, explosion-proof valve, ladder, and guardrail

Installation, Commissioning, and Maintenance Support

Our engineers completed the following services at the Manila construction site:

Site Survey: Confirmed that the foundation and installation location met the requirements.

Assembly Guidance: Provided guidance on lifting and bolting to ensure the silo was vertical and stable.

Commissioning: Inspected the dust collector, screw conveyor, and arch breaker to ensure system operation.

Operation Training: Provided training to local workers, covering daily operation, cleaning, and maintenance.

After-sales Maintenance: Provided online technical support and regular maintenance recommendations.

Customer Benefits

I. Stable Supply: More ample cement storage prevents production stoppages due to raw material shortages.

II. Reduced Costs: Modular cement silos save approximately 30% in freight costs.

III. Improved Efficiency: Uniform and smooth material discharge ensures continuous production at the concrete mixing plant.

IV. Environmentally Friendly and Safe: The dust removal system effectively reduces dust, meeting environmental requirements.

Customer Testimonials

During a follow-up visit, a customer commented:

“Daswell’s 100-ton cement silo fully met our needs. Transportation and installation went smoothly, and the after-sales service was excellent. Compared to our previous silo, this one is more durable and operates more stably. We are very satisfied!”

Conclusion

This successful sale of a 100-ton cement silo to Manila, Philippines, further demonstrates Daswell Machinery’s competitiveness in the overseas market. We not only provide high-quality cement silos for sale, but also provide comprehensive services from project planning to after-sales service.

Whether you need a 100-ton cement silo, bolted cement silo, or cement storage silo in the Philippines, Daswell can provide the optimal solution!