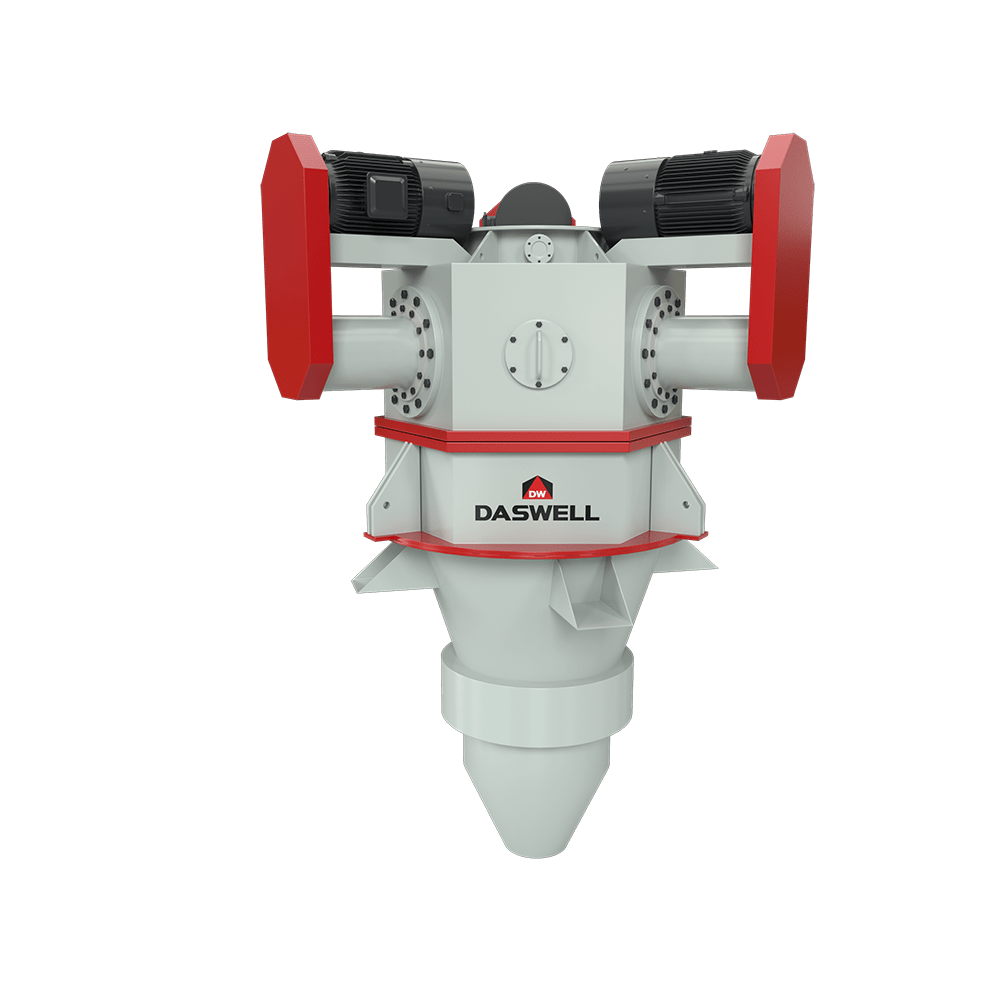

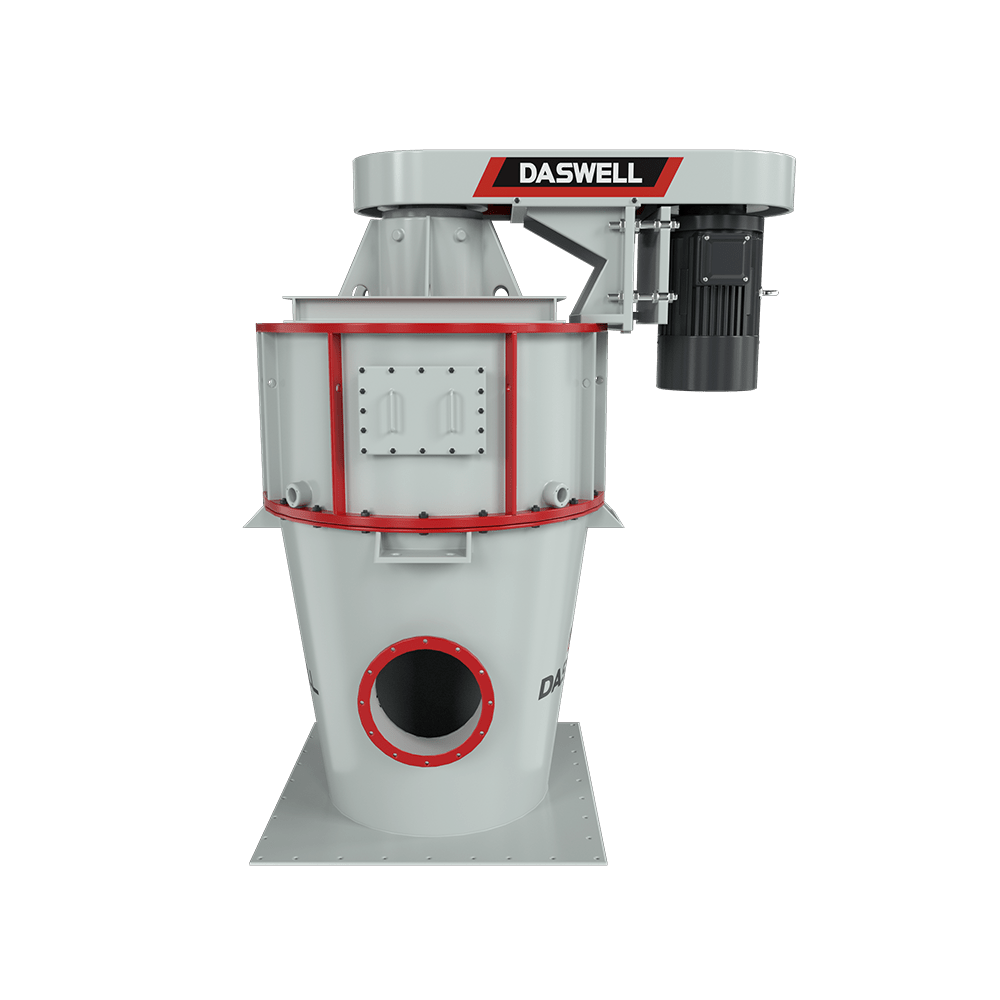

Turbo Classifier

High-precision classification solutions for calcium carbonate, talc, quartz, and other mineral powders

The Daswell turbo classifier is designed for high-efficiency and high-accuracy powder classification in modern industrial production. Using an advanced forced-vortex design and horizontally installed classifier wheel, it ensures precise particle size control and stable performance for ultrafine powders.

It is widely suitable for classifying heavy calcium carbonate (GCC), light calcium carbonate (PCC), talc, kaolin, barite, wollastonite, silica powder, dolomite powder, ceramic powder, pharmaceutical powder, pesticide powder, and many other inorganic or organic materials.

Daswell turbo classifiers effectively solve key challenges such as inconsistent particle size, excessive coarse particle residue, and low efficiency in traditional separation systems. Optimized solutions can be provided based on material characteristics, production capacity requirements, and product fineness targets.

High-precision Classification Solutions for Ultrafine Mineral Powders

Powder classification is one of the most critical steps in modern mineral processing. Whether the goal is to produce ultrafine calcium carbonate for high-end plastics, kaolin for ceramic applications, or silica powder for coatings and electronics, the stability of particle size distribution directly determines the performance of the final product.

Daswell provides a full range of industrial classifier systems engineered to deliver stable, accurate, and energy-efficient particle size control. Equipped with advanced vortex technology and German NG classifier wheels, our systems ensure clean cut points, narrow particle size distribution, and continuous, reliable operation for high-capacity powder processing lines.

Suitable for:

GCC, PCC, talc, kaolin, silica, barite, dolomite, ceramic powder, pharmaceutical powder, pesticide powder, and other inorganic or organic materials.

Why Powder Classification Matters in Modern Production

Precise powder classification goes far beyond achieving a target D97 value. In many industries, performance issues such as poor dispersion, reduced opacity, low whiteness, weak reinforcement, or unstable viscosity all trace back to inaccurate particle size control.

Traditional low-efficiency classifiers often face problems such as:

Daswell classifier systems are designed to eliminate these limitations by providing:

Working Principle of Daswell Classifier Systems

Daswell classifier systems operate through a controlled forced-vortex separation process:

- Powder enters the classifying chamber through the feeding system.

- High-speed rotating wheels create a strong centrifugal field.

- Coarse particles lose velocity and fall back into the grinding system.

- Fine particles pass through the rotor gap and are carried by airflow into the cyclone and dust collector.

- Powder fineness is precisely controlled by adjusting rotor speed and airflow volume.

- A closed-loop system ensures efficiency, stable fineness, and low energy consumption.

This principle delivers exceptional consistency even in demanding ultrafine ranges.

Turbo Classifier Technical Specifications

AMS Multi-wheel Classifier Parameters

| Model | Feeding (t/h) | D97 Range (μm) | Output (t/h, D97=10μm) | Wheel Qty | Power (kW) |

|---|---|---|---|---|---|

| AMS4001Z | 0.3–0.5 | 3–37 | 0.1–0.2 | 1 | 5.5 ×1 |

| AMS4003Z | 1.0–1.5 | 3–37 | 0.3–0.4 | 3 | 5.5 ×3 |

| AMS6301Z | 0.5–2.0 | 4–37 | 0.4–0.5 | 1 | 15 ×1 |

| AMS6303Z | 1.5–7.0 | 4–37 | 1.3–1.5 | 3 | 15 ×3 |

| AMS6304Z | 3.0–10.0 | 4–37 | 1.7–2.0 | 4 | 15 ×4 |

| AMS6306Z | 6.0–15.0 | 5–37 | 2.7–3.0 | 6 | 15 ×6 |

| AMS8001 | 1.0–3.0 | 5–37 | 0.6–0.8 | 1 | 18.5 ×1 |

| AMS8003 | 3.0–10.0 | 5–37 | 1.8–2.2 | 3 | 18.5 ×3 |

| AMS8004 | 4.0–15.0 | 5–37 | 2.6–3.0 | 4 | 18.5 ×4 |

| AMS10001NG | 2.0–5.0 | 5–37 | 1.0–1.2 | 1 | 30 ×1 |

| AMS10003NG | 6.0–18.0 | 5–37 | 3.1–3.5 | 3 | 30 ×3 |

| AMS10004NG | 8.0–25.0 | 5–37 | 4.2–4.6 | 4 | 30 ×4 |

| AMS10006NG | 12.0–35.0 | 5–37 | 6.0–6.8 | 6 | 30 ×6 |

ASS Single-wheel Classifier Parameters (8–25 μm)

| Model | Feeding (t/h) | D97 Range (μm) | 10μm Output (t/h) | Power (kW) |

|---|---|---|---|---|

| ASS500 | 2–6 | 5–37 | 1.0–1.3 | 30 |

| ASS630 | 4–12 | 6–37 | 1.5–1.8 | 45 |

| ASS830 | 6–18 | 8–37 | 2.1–2.4 | 55 |

| ASS900 | 8–22 | 9–37 | 2.6–3.0 | 75 |

| ASS1000 | 10–28 | 9–37 | 3.2–3.5 | 75 |

| ASS1100 | 12–32 | 10–37 | 3.7–4.1 | 90 |

| ASS1200 | 15–38 | 12–37 | 4.3–4.5 | 110 |

| ASS1300 | 18–45 | 15–37 | — | 110 |

Why Choose Daswell

With more than 30 years of engineering experience in mineral processing and a global team in the Philippines, Indonesia, Egypt, and China, Daswell provides:

Complete EPC solutions from grinding → classification → modification → packaging

Localized service teams for installation, commissioning, and after-sales support

High reliability, stable operation, and long-term engineering focus

Custom solutions tailored to your material and production goals

Daswell represents engineering-first, long-termism, and global reliability.