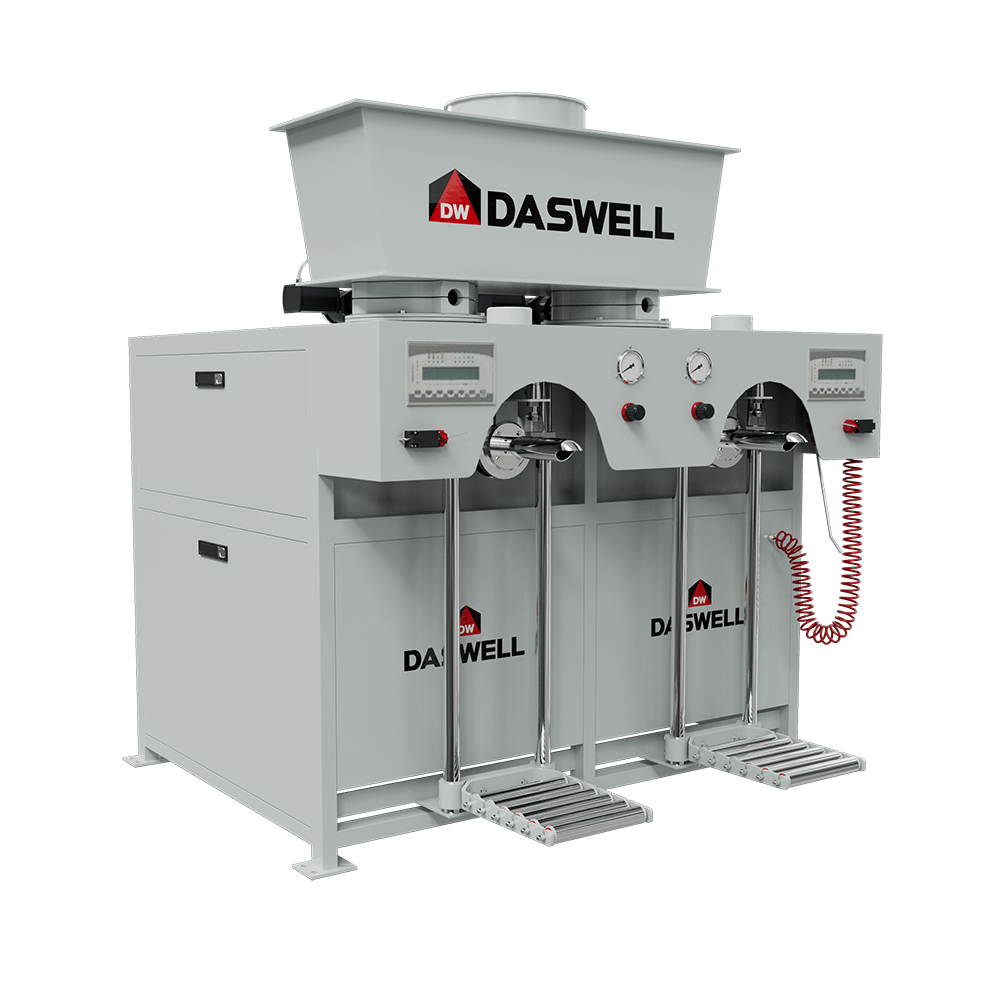

Industrial Powder Packaging machine

Automated packaging solutions for calcium carbonate, talc, and quartz powder

This packaging machine is used for high-speed, high-precision packaging of powder materials. It is suitable for valve bag packaging of heavy calcium carbonate, ordinary light calcium carbonate, talc, magnesium oxide, iron oxide, aluminum oxide, magnesium hydroxide, bentonite, kaolin, wollastonite, lithopone, mica powder, dolomite powder, aluminum powder, carbon black, silica, desulfurization powder, and other mineral or chemical powders.

Daswell packaging machines effectively solve problems related to weighing, sealing, high dust levels, and high labor intensity. Optimal solutions can be provided to users based on the production environment, material characteristics, and equipment usage requirements.

Why Choose the Daswell Industrial Powder Packing Machine

Designed for mineral powders (not food powders)

High accuracy: ±0.2–0.5 kg depending on material

Dust-free filling with pulse dust collector

Supports 5–60 kg bags (valve bag / open-mouth bag)

High output for continuous bulk production

Compatible with your grinding & crushing plant

Easy maintenance and robust structure

Packing Machine Types

1) Valve Bag Packing Machine

Best for:

Calcium carbonate (GCC/PCC)

Talc powder

Quartz powder

Cement & lime

Features:

Automatic weighing + filling

Air-blown filling system

Automatic bag-release

Stable performance for fine mineral powders

Industrial Powder Packaging Machine Technical Specifications

| Parameter | DP-1 | DP-2 | DP-5 | DP-7 |

|---|---|---|---|---|

| Type | Automatic Powder Packing Machine | Fine Powder Packing Machine | Compacting Type Powder Packing Machine | Vacuum Powder Packing Machine |

| Applicable Materials | Calcium carbonate, talc, quartz powder, limestone, mineral powders | Ultrafine CaCO₃, talc D97 10–20μm, light powders | High-density powders, dusty powders, poor-flow materials | High-value powders, chemical powders, dry powders |

| Feeding Method | Screw feeding | Air-blown + screw feeding | Screw feeding + compacting system | Vacuum feeding & sealing |

| Weighing Range | 5–60 kg | 5–60 kg | 5–60 kg | 5–50 kg |

| Accuracy | ±0.2–0.5 kg | ±0.2–0.4 kg | ±0.3–0.5 kg | ±0.2–0.4 kg |

| Packing Speed | 4–8 bags/min | 3–6 bags/min | 3–6 bags/min | 2–4 bags/min |

| Power | 2.2–3 kW | 3–4 kW | 3–4 kW | 4–6 kW |

| Air Requirement | 0.4–0.6 MPa | 0.4–0.6 MPa | 0.5–0.7 MPa | 0.5–0.7 MPa |

| Notes | Standard model for mineral powders | Optimized for ultrafine/light powders | With powder compaction system | Vacuum packaging for sensitive powders |

Applications

Daswell industrial powder packaging machines are widely used in:

Limestone and cement processing

Dry mortar production

Paint and coating powders

Mining and mineral processing

Chemical powder industry

Daswell packaging machines are specifically designed for industrial powders, avoiding common packaging problems associated with ultralight or sticky materials.

Advantages for your powder production line:

Stable and continuous packaging even for ultrafine powders

Highly compatible with Ball Mills, Ring Roller Mill, and Raymond Mill.

Low maintenance costs and long service life

Flexible bag sizes to meet the needs of 5–60 kg

Fast return on investment due to low labor costs

Dust-free operation ensures a cleaner factory environment

Daswell provides a complete powder processing solution that is compatible with our other equipment, reducing your production losses.

Contact Daswell

Contact us to get a customized powder packing solution for your calcium carbonate, talc, or quartz powder plant.

No matter where you are, Daswell can provide you with personalized service. Find sales and service contact details and general information, or submit a sales inquiry.