Stationary Crushing Plant in Philippines

The stationary crushing plant is a set of fixed installation equipment. It is often used to produce sand and gravel aggregates used in construction, highways, railways, mining and other industries in Philippines.

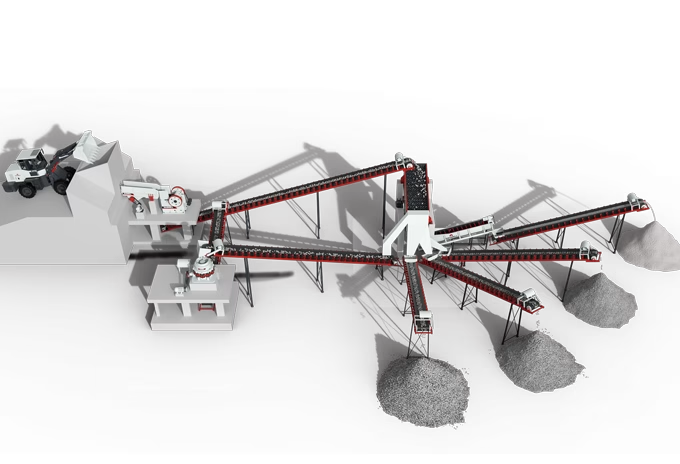

Generally speaking, a crushing plant is an entire production line composed of different equipment such as jaw crusher, cone crusher, sand making machine, vibrating screen, and belt conveyor.

Contact our local Philippines team at +63 915 802 0960 for personalized assistance and a fast quote!

Stationary crushing plant is a fixed installation unit. It is designed to crush rocks, ores, and other materials for construction, mining, or industrial use. Different from the mobile type crusher plants, the stationary type is permanently set up at a specific location.

You can use it near quarries, construction sites, or industrial zones. For your reference, our stone crushing plant is popular in highways, water conservancy, mining, and other industries in Philippines.

Wide applications of Daswell stationary crushing plant in Philippines

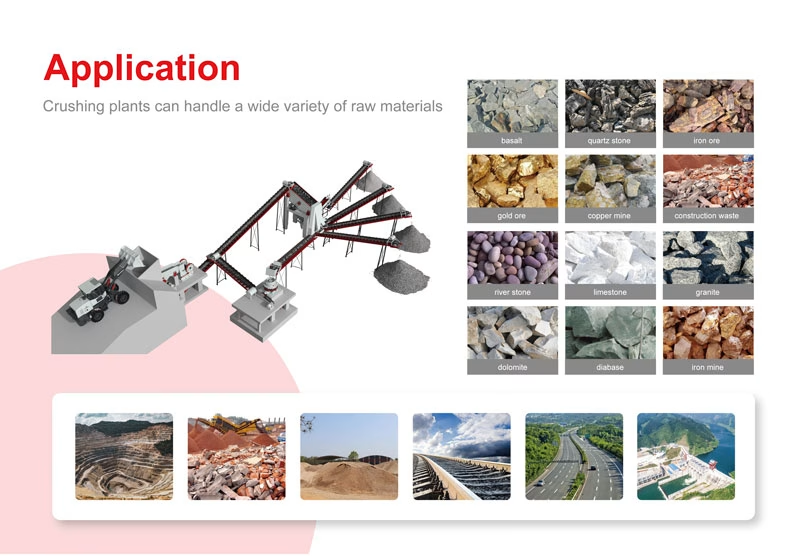

Daswell stationary stone crusher plant can handle different types of materials. For different materials, you should customize crushers and configurations. Our crusher plant can process river pebbles, limestone, construction waste, iron ore, gypsum, etc.

Main applications of the stone stationary crusher plant

Mining and quarrying: It can process ores and rocks into usable materials. For example, the crushed ores can be further processed for metallurgical.The crushed rocks are suitable for construction aggregates producing.

Waste recycling: After the construction demolition, the waste, such as concrete, bricks or asphalt can be crushed into new building materials. For your reference, Daswell has complete concrete machinery, brick making machines and asphalt production line.

Construction and infrastructure: It is applicable for producing sand, gravel and crushed stone for concrete, asphalt, and road base. Besides, it also helps supply materials for bridges, dams, highways and buildings.

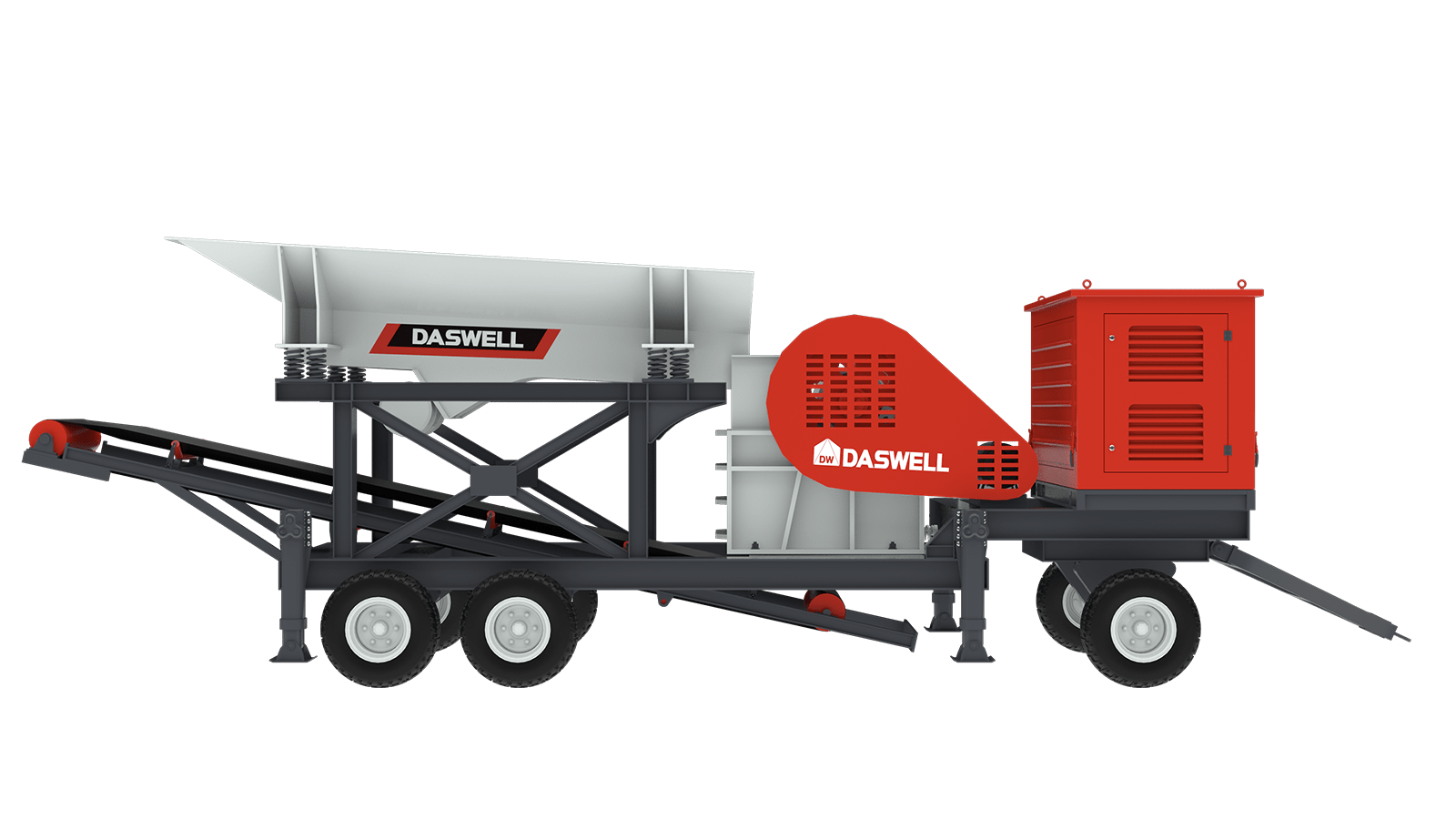

Daswell has various crushers for different materials crushing. If you do not know which crushing machine is suitable for you, just send an inquiry to us. We will recommend you the most suitable machine configurations according to your project scale, materials, working conditions, and the budget. For your reference, Daswell in Philippines also has mobile type crushing plant for your quick relocation needs.

For more details, please contact our Philippine Team.

Different Crushing Machine Configurations for Your Reference

Why invest in a stationary aggregate crushing plant in Philippines?

With rapid urbanization and infrastructure development in Philippines, the demand for sand and gravel aggregate crushing plant is essential. It can produce construction materials efficiently and profitably.

High demand: The growing construction projects require a steady supply of aggregates in Philippines.

Cost-effective production: The stationary crushing plant can crush the stones on-site. That reduces the transportation costs.

Customizable solutions: Daswell can provide different configurations for your stone crushing plant requirements in Philippines. According to your materials, such as limestone, granite, basalt, recycled concrete, we can customize for you. If you do not know how to configure the stationary crushing plant for your Philippine project, Contact Daswell and we will offer you customizable solutions.

Long-term profitability: Reliable equipment ensures production and high ROI. Daswell aggregate stationary crusher plant is configured high-quality single equipment. And we have been exporting various crushing machine to many countries for many years. Especially, we have Philippine office to serve our customers better. You can trust Daswell machinery.

Cases of Daswell Stationary Crushing Plant in Philippines

How does the stationary crushing plant help your Philippine project?

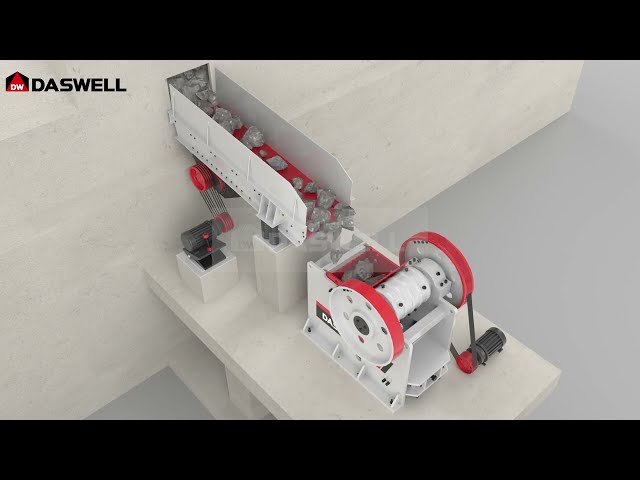

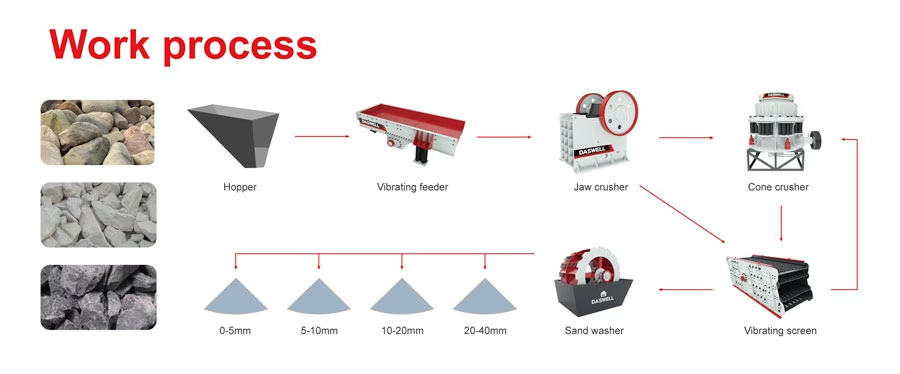

The stationary crushing plant mainly includes crushing part and screening part. The whole process involves feeding, crushing, screening, transportation. And if you need, we can also provide sand making facilities to achieve the high precision finished product sizing for your Philippine project. Here are detailed workflow for a configured production line. It includes key equipment, such as vibrating feeder, jaw crusher, cone crusher, vibrating screen, and belt conveyors.

- Raw material transport: Transport the materials from quarry to the plant. You can use a backhoe loader or other haulage equipment for transportation. Daswell provides high-efficiency backhoe loaders for you to use in Philippines.

- Feeding: The vibrating feeder can deliver the raw materials to the jaw crusher uniformly for primary crushing. Using vibrating feeding machine, it can prevent blockages and ensure steady capacity.

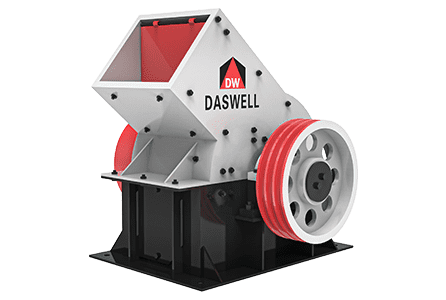

- Primary crushing(Jaw crusher): For the primary crushing, the jaw crusher machine is commonly used. Large size materials will be reduced to smaller chunks by using the jaw crusher.

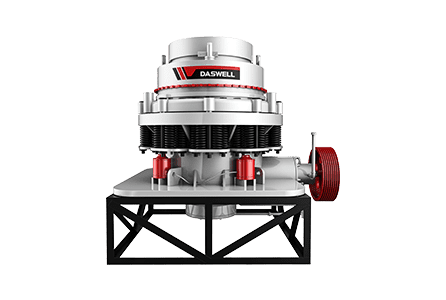

- Secondary crushing(Cone crusher): If you need thinner aggregates, it is applicable for you to use the cone crusher equipment for secondary crushing. There are belt conveyors, which can convey the crushed materials to the cone crusher for finer crushing.

- Screening(Vibrating screen): After the crushing, there is a vibrating screen for classification. The qualified particles will be sent to the stockpile directly by conveyor. And the oversized particles will be returned to the cone crusher for re-crushing.

- Optional sand-making: If you need high-precision shaping or sand production. We can also offer you sand maker after the screening process.

Working Video of Daswell Stationary Crushing Plant

For your reference, the material properties, your output requirements, and the dust and noise control will influence the crusher plant configurations. Our engineer will optimize the equipment and layout to balance efficiency, cost, and output quality. If you want to know more details, please send inquiry to us. And you can also visit our Philippine office.