Home » Stone Crushers

Stone Crushers

Stone Crushers mainly crush large stones into small stones that meet construction standards.

Stone Crushers crushing machines are often utilized in aggregate production, construction material recycling, and mining operations.

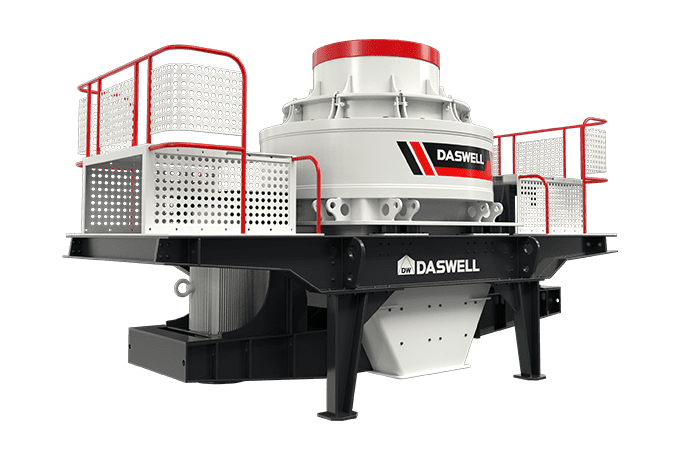

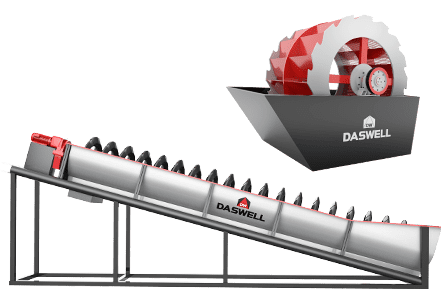

Daswell Stone crushing equipment includes a jaw crusher, cone crusher, sand-making machine, an impact crusher, etc.

Stone Crusher Machine

Our Stone Crusher Equipment

Powerful Solutions for Mining, Aggregates, and Mineral Processing

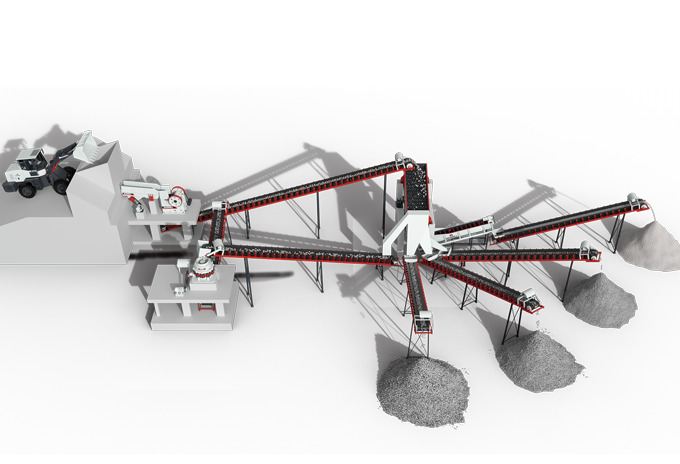

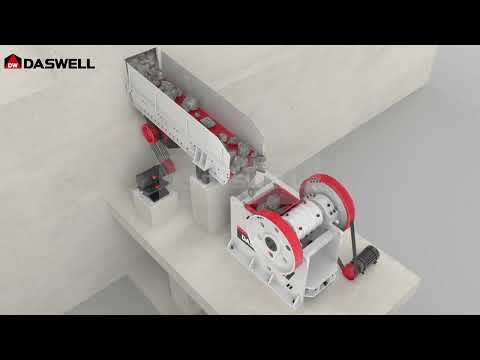

Raw materials are often extracted in large, unrefined forms in the mining, aggregates, and mineral processing industries—far too bulky and irregular for direct use or sale.

These raw resources, such as mined rock, stone, ore, and construction debris, must be crushed into smaller, manageable sizes to improve handling, enhance processing efficiency, and increase their commercial value.

Daswell crusher machines are engineered to meet this challenge with strength, precision, and durability.

Our crushers can efficiently reduce large and medium-sized rocks into uniform particles suitable for further processing or end use, whether dealing with hard granite, limestone, basalt, or metallic ores. This not only maximizes output but also reduces transportation and processing costs for downstream operations.

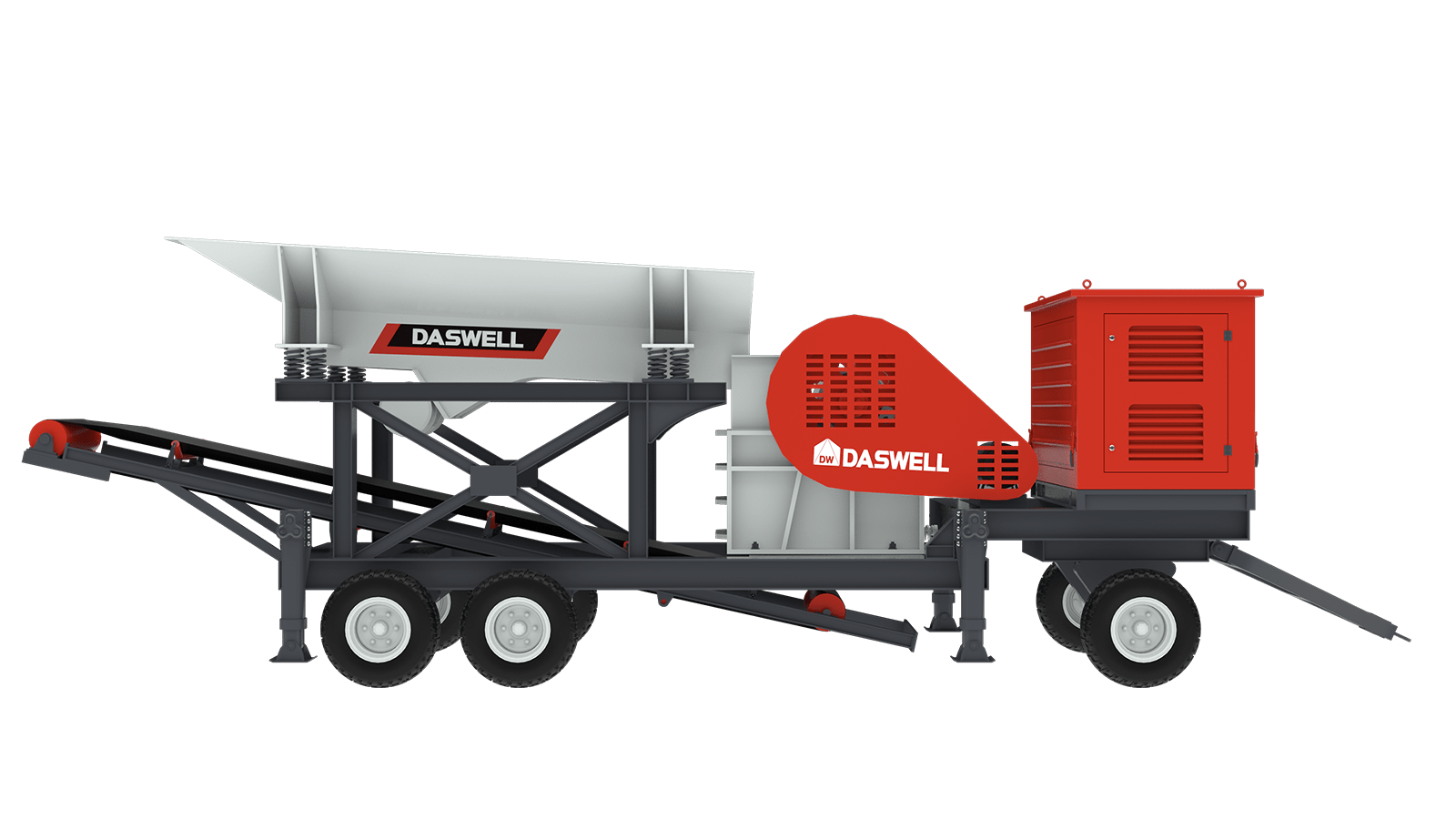

Our product range includes jaw crushers, cone crushers, impact crushers, and hammer crushers, with mobile crushing equipment and stationary crushing plants customised to your needs – each designed to suit different stages and requirements in the crushing process.

With robust construction, optimized chamber designs, and energy-efficient systems, Daswell crushers ensure stable performance, minimal downtime, and extended service life, even in the most demanding environments.

Advantages of Daswell crushers

From large-scale mining operations to compact on-site crushing solutions, Daswell provides the technology and support to help you process materials faster, smarter, and more profitably.

Let’s Make Your Next Project a Success with Daswell

With reliable machinery, expert support, and years of export experience, Daswell is your trusted partner in industrial equipment. We offer tailored solutions based on your materials, production needs, and local conditions, helping you work smarter, faster, and more efficiently.

Quickly contact our sales experts.

Our technical team will get back to you with a personalized quote and free consultation.

Crushing equipment comparison table

Help you choose the crushing equipment that suits you

|

Feature / Type |

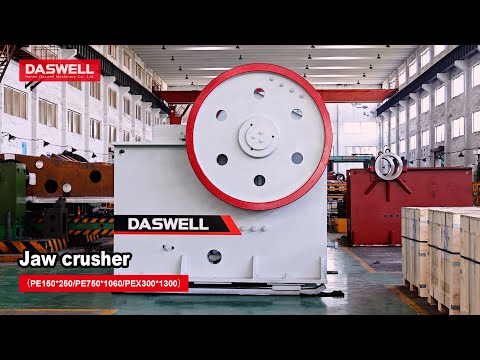

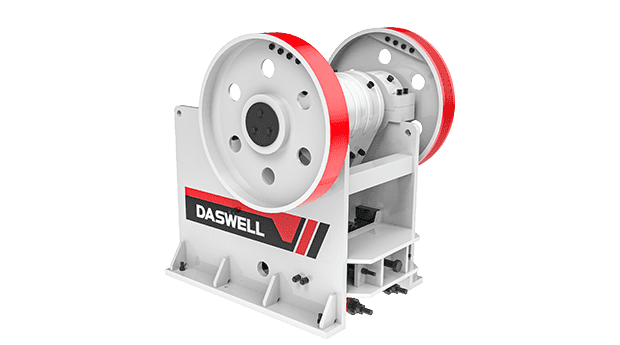

Jaw Crushers |

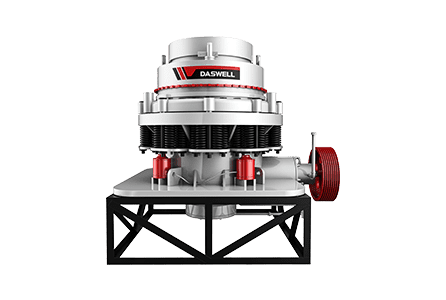

Cone Crushers |

Impact Crushers |

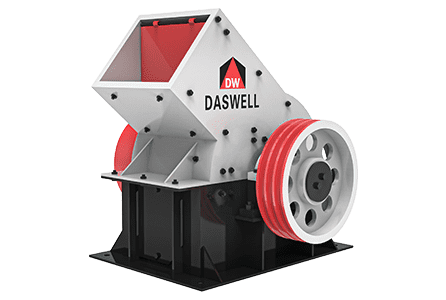

Hammer Crushers |

|---|---|---|---|---|

|

Image |

|

|

|

|

|

Crushing Method |

Compression |

Compression |

Impact |

Impact + Shearing |

|

Material Feeding Size |

Large |

Medium |

Medium |

Small to medium |

|

Final Output Size |

10–300 mm |

Fine to very fine |

Fine |

Coarse to medium |

|

Suitable Materials |

Medium-hard materials |

Hard and abrasive rocks |

Brittle materials |

Mining, quarrying, infrastructure, and aggregate production |

|

Primary Use |

Primary crushing (first stage) |

Secondary / Tertiary crushing |

Secondary crushing |

Primary / Secondary (varies by size) |

|

Shape of Final Product |

Less uniform (flaky or angular) |

Uniform and cubic |

Good cubic shape with less flakiness |

Irregular, often powdery |

|

Output Capacity |

High |

Very High |

Medium to High |

Medium |

|

Energy Efficiency |

Moderate |

High |

Moderate |

Moderate |

|

Wear & Maintenance |

Low to moderate |

Moderate |

Construction waste, aggregate, and concrete recycling |

Higher |

|

Typical Applications |

Mining, quarrying, infrastructure, and aggregate production |

Mining, metallurgy, sand making, aggregate |

Construction waste, aggregate, and concrete recycling |

Cement, coal, brick, chemical plants |

Not sure which crusher is right for your project? Contact Daswell today for expert guidance and tailored recommendations.