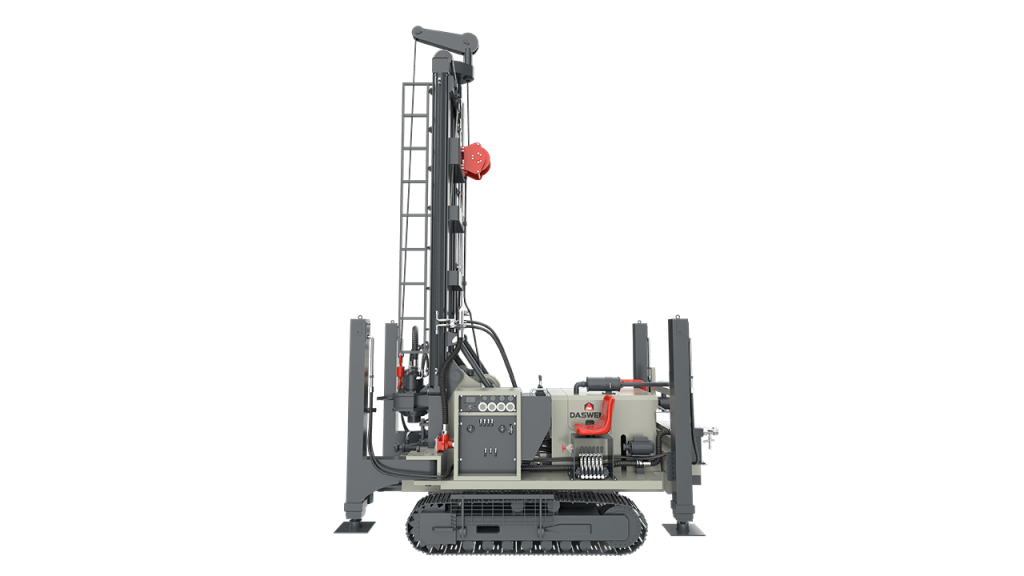

Water well Drilling Rig

A Water well Drilling Rig is specialized equipment designed primarily for drilling water wells. It is used to penetrate underground layers of soil and rock to access groundwater sources for agricultural, residential, industrial, or commercial use. These rigs can drill to significant depths and are equipped to handle various ground conditions.

A water well drilling rig is a specialized mechanical system designed for drilling deep water wells and completing related operations such as casing installation and well construction. It typically includes power equipment, drill bits, drill pipes, core barrels, and a drilling mast.

Daswell water well drilling rigs are available in two main types: crawler-mounted and truck-mounted, offering flexibility for various terrains and mobility needs. Depending on geological conditions, our rigs are capable of drilling as deep as 1000 meters, making them suitable for agricultural irrigation, residential water supply, and industrial groundwater extraction.

With powerful performance, reliable structure, and easy operation, these rigs are built to deliver efficient and precise drilling even in challenging environments.

Full hydraulic top drive crawler water well drilling rig is a multifunctional water well drilling equipment. It adopts new hydraulic technology and is mainly used in mining engineering construction, ground source heat pump wells, civil draft wells, rural poverty alleviation wells, agricultural irrigation wells, and other wells, and is suitable for drilling and water intake projects in mountainous and rocky strata with complex geology. The equipment has a beautiful appearance, compact and reasonable structure, fast installation speed, low failure rate, economical and durable, and high cost performance.

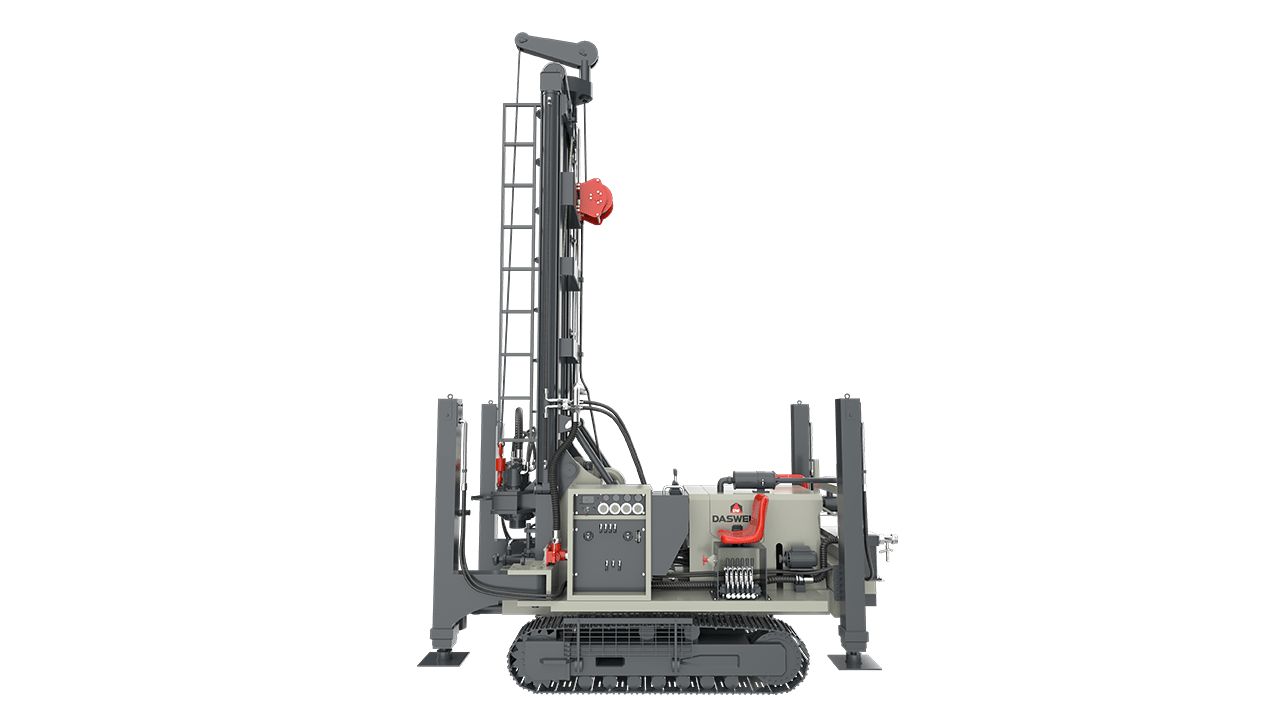

Components of a water well drilling rig

Adopt Yuchai Engine

Electronic control: Electronically controlled fuel injection, lower fuel consumption, and more environmentally friendly.

Electronic control technology: The use of electronic control technology effectively reduces the phenomenon of wandering, turning, and white smoke.

Convenient maintenance: It can automatically display engine fault codes for easy maintenance.

Brand engine: The well-known brand engine provides sufficient power for the hydraulic system.

Mature and reliable hydraulic top drive power head

Bearing capacity: The main shaft adopts a bearing with a large bearing capacity, which has a larger bearing capacity and higher drilling accuracy.

Strict hydraulic debugging: The main shaft seal adopts multiple sets of seal designs to ensure the sealing effect.

Air faucet: The air faucet adopts the company’s proprietary sealing technology and has a long service life.

Large stroke telescopic drilling mast

Long stroke design: Long stroke design, to meet the needs of 6 meters of pipe drilling

Reduce wear and tear: The inner and outer drill frames adopt wear-resistant blocks with adjustable gaps, which can effectively reduce the wear of the drill frame and reduce maintenance costs.

Unique hydraulic matching technology

Diversion technology: Multi-pump confluence and diversion technology minimizes system heating and fuel consumption.

Feed system: The integrated fine feed system has a small pressure loss and can precisely adjust the drilling pressure according to the weight of the drilling tool in the hole.

Locking System: The hydraulic locking system is adopted to prevent the power head from falling automatically.

Balance valve: The lifting cylinder adopts a load balancing valve, and the drilling frame lifts and falls smoothly without impact

Hydraulic technology: The drilling rig adopts new hydraulic technology, supporting high-torque hydraulic rotation.

Safe and considerate detail design

Emergency stop button: Emergency stop buttons in many places to ensure the safety of machines and personnel;

Low maintenance costs: The centering disc adopts a replaceable wear-resistant sleeve, and the maintenance cost is low;

Anti wear: Multi-pipeline synchronous guide anti-wear mechanism to reduce pipeline wear;

Auxiliary support: The chassis of the drilling rig is equipped with hydraulic high outriggers, which can be used for leveling, loading and unloading of the drilling rig, and can also be used as auxiliary support during operation;

Track chassis: The drilling rig adopts a crawler with strong off-road performance, safety and reliability.

Advantages of Daswell water well drilling rig

- Flat work table for easy cleaning of mud

- Chain wheel protection to prevent mud from entering the machine

- Hydraulic system upgrade , more flexible operation

- Intuitive operation with no dead space

- Optional auxiliary hoist, high work efficiency

- The tower oil cylinder is thickened, and the lifting force is large

Hydraulic water well drilling rig features:

Strong adaptability

Our water well drilling rig adopts crawler chassis, which is highly adaptable and can be moved flexibly in complex terrain conditions without being restricted by the terrain, and can meet the needs of different work sites.

Adopt high-quality hydraulic components

It adopts hydraulic components of famous brands at home and abroad, which have the advantages of high reliability, high durability, high safety and low maintenance cost.

Convenient operation

Adopt the intelligent control system, convenient and humanized to operate, which reduces the labor intensity of operators and improves production efficiency

Compact structure

Advanced design technology, compact structure, small footprint, and convenient for drilling operations in small spaces.

High drilling efficiency

The water well drilling rig is equipped with a powerful power system and top drive system, which has high drilling efficiency and can meet the drilling needs of different depths

High degree of automation

The intelligent control system and the operation functions such as automatic inlet and outlet of the drill pipe, automatic inlet and outlet of the drill hole and automatic addition of liquid improve the production efficiency and reduce the operation errors and human accidents.

Simple maintenance

With advanced design technology and high-quality hydraulic components, the failure rate is low, and maintenance is simple, which reduces maintenance costs.

Technical Data:

| Item | DWR200 | DWR260 | DWR300B | DWR300 |

| Drilling depth (m) | 200-300 | 260-350 | 300-366 | 300-366 |

| The hole diameter (mm) | 138-325 | 138-325 | 138-325 | 138-325 |

| Rotary Head Sliding Travel (mm) | 3700 | 3700 | 3700-4800 | 6600 |

| Diesel Engine | YUCHAI73KW | YUCHAI78KW | YUCHAI85KW | YUCHAI91KW |

| Max climbing angle (°) | 6000-8000 | 8000-10000 | 10000-12000 | 10000-12000 |

| Swing Speed(rpm) | 30-150 | 30-150 | 30-150 | 30-160 |

| Rig lifting force (T) | 18 | 18 | 25 | 30 |

| Drill pipe diameter | 76/89/102 | 76/89/102 | 76/89/102 | 76/89/102 |

| Moving Way | Hydraulic crawler | Hydraulic crawler | Hydraulic crawler | Hydraulic crawler |

| Moving Speed (km/h) | 2.5 | 2.5 | 2.5 | 2.5 |

| Max climbing angler (°) | 30 | 30 | 30 | 30 |

| Dimension(mm) | 3000*1400*2000 | 3400*1500*2200 | 3500*1500*2200 | 3800*1700*2300 |

| Weight (T) | 5.5 | 6 | 7 | 7.6 |

| Item | DWR350 | DWR400S | DWR500 | DWR600 |

| Drilling depth (m) | 400-500 | 450-560 | 500-600 | 600-700 |

| The hole diameter (mm) | 138-325 | 138-325 | 138-325 | 138-325 |

| Rotary Head Sliding Travel (mm) | 6600 | 6600 | 6600 | 6800 |

| Diesel Engine | YUCHAI91KW | YUCHAI92KW | Weichai129KW/Cummins132KW | Cummins132KW |

| Swing torque (N.m) | 13000-15000 | 13000-15000 | 15000-20000 | 16000-20000 |

| Swing Speed(rpm) | 0-60/0-120/0-240 | 0-60/0-120/0-240 | 0-60/0-120/0-240 | 0-60/0-120/0-240 |

| Rig lifting force (T) | 35 | 38 | 40 | 40 |

| Drill pipe diameter | 76/89/102 | 76/89/102 | 76/89/102 | 76/89/102/102 |

| Moving Way | Hydraulic crawler | Hydraulic crawler | Hydraulic crawler | Hydraulic crawler |

| Moving Speed (km/h) | 2.5 | 2.5 | 2.5 | 2.5 |

| Max climbing angler (°) | 30 | 30 | 30 | 30 |

| Dimension(mm) | 3800*1700*2300 | 3900*1850*2380 | 4000*1900*2480 | 4200*2000*2600 |

| Weight (T) | 8 | 9 | 10 | 11.5 |