The Key Advantages of Using a Ball Mill Grinding Machine

Ball milling is a widely used mechanical grinding technique. It offers great benefits for material processing. Especially, for your fine powder production plant, it plays an important role. For example, you can use it for grinding quartz, calcium carbonate, talc powders and so on. It is the most popular milling machine in Daswell. Do you know the reason it is popular? Do you know its advantages?

What are the advantages of ball mill grinding machine?

The ball mill grinding equipment can produce powders from coarse to ultra-fine particle sizes. And you can control the size simply. The fineness of the finished powder is better than ring roller type and Raymond mills. Meanwhile, as long as your materials mosh hardness is under 7, the ball mill machine is available for processing your materials into powders.

Versatile size reduction capacity

The ball milling facility can produce powders from 5 micron to 200 micron. Whether you need coarse powder or ultra-fine powder, the ball mill grinding machine can meet your needs. And Daswell utilizes PLC control system, so that you can adjust the rotating speed. The speed will influence the particle sizes. Compared with the ring roller mill machine and Raymond mill equipment, it is more suitable for grinding hard materials.

High operational efficiency

It can process large quantities. Daswell can customize ball mill grinding equipment according to your capacity. It is adaptable to both batch and continuous processing. Compared with the other two grinding mills, even though the production capacity is same, the ball mill machines cost less consumption.

Process control flexibility

With Daswell ball mill grinding facilities, you can adjust the rotation speed, milling time, ball-to-powder ratio, and temperature control. These factors will influence the milling effects. It is applicable for your different production requirements. Besides, the grinding media, mill lining materials, continuous or batch processing, and wet or dry grinding options are optional. You can send messages to our team, our technical engineers will customize for you according to your materials, required capacity, required sizes, etc.

Wide material compatibility

This ball mill equipment can be used for processing diverse materials. For instance, you can use it to process hard minerals, such as quartz, alumina, zirconia, talc, calcium carbonate, etc.

How does ball mill grinding machine process powders Efficiently?

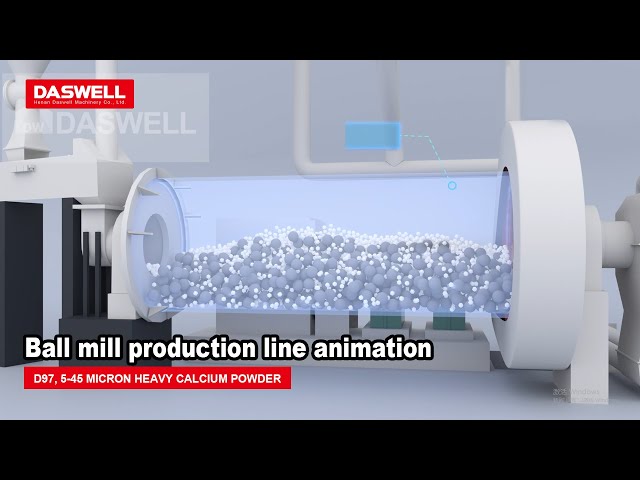

Ball mill grinding facility mainly utilizes the grinding media for grinding the materials. Usually, the grinding media is steel or ceramic balls. These grinding media use the impact, attrition, and abrasion to reduce the particle size and blend materials uniformly. Here you can learn the processes in detail.

Loading the material

Feeding the raw material into the ball mill’s rotating drum with the grinding media. Generally, the drum is filled to about 30% to 50% of its volume with grinding media and 20% to 40% with materials. These allow proper movement and grinding action.

Rotation and grinding mechanism

The drum rotates around a horizontal axis at a controlled speed. When the drum rotates, the balls will be lifted to a certain height and then down, impacting and grinding the powder. The impact breaks the larger particles with high-energy collisions. The friction between particles and balls reduces particle size. Finally, the shear forces further refine the powder.

Particle size reduction

The repeated collisions and friction gradually reduce the particle size. As grinding continues, finer particles are produced. There are 4 factors that influence the final size.

- Grinding time: The longer the grinding time, the finer the powder.

- Ball size and material: The smaller the balls, the finer the powder.

- Rotational speed: The faster the rotating speed, the more the impact force.

- Material properties: The hardness, brittleness, and moisture content of the material, influences the grinding effects.

Discharge and collection

After sufficient grinding, the powder will be discharged through the screen or grate. It can separate powders from the grinding media. You can also equip an air classifier and the dust collectors. The air classifier can classify the powder sizes. And the dust collectors will collect the finished powder products for packing conveniently.

What raw materials are suitable for ball mill processing?

Ball mills are versatile grinding machines. They are capable of processing a wide range of raw materials into fine powders for various industrial applications. The most common materials include calcium carbonate-based compounds. The calcite, marble, limestone, and chalk are calcium carbonate-based compounds. These minerals are widely utilized in industries such as paper, plastics, paints, and construction.

Kaolin is also called china clay. It is a soft white clay. It is essential for ceramics, paper coating, and refractory products. Using a ball mill machine for making Kaolin powder, it can improve kaolin’s plasticity and brightness while reducing impurities. It is ideal for high-grade porcelain and sanitaryware production.

Dolomite is a carbonate mineral. It is another key material for ball mills. It is widely used in steelmaking, glass manufacturing, and soil conditioning. Ball milling enhances its reactivity and ensures uniform particle size. It is critical for metallurgical and agricultural applications.

Additionally, quartz is a hard and abrasive silica mineral. You can use ball mill machines for processing quartz powder for glass, ceramics, and engineered stone. During the ball mill grinding process, you can control the particle shape and size. These directly influence the product strength and clarity.

There are other processable materials, including feldspar, talc, gypsum, and bentonite. Each of them requires specific milling parameters to achieve the desired fineness and functional properties. Daswell has various mill plant solutions for your different materials processing.

Where can you use the ball mill grinding machine?

Ball mill grinding machines are versatile and you can use it for various industries. It can realize size reduction, mixing, homogenization, and mechanical alloying of the powders. Here you can learn some key applications of the ball mills in different fields.

Mining and metallurgy

Ore grinding: You can crush the ore and grind it into fine powder for further extraction.

Cement production: The ball mill machine can grind clinker, gypsum, and additives to produce cement.

Limestone and calcite processing: You can produce fine powders for fillers, coatings, and construction materials.

Ceramic and glass industry

Ceramic raw material grinding: It prepare alumina, silica, and clay for ceramic production.

Glaze and enamel preparation: It ensures smooth, homogeneous mixtures for coating applications.

Glass batch grinding: It can crush raw materials before melting.

Cosmetics

Cosmetic powders: With ball mill grinding machine, you can grind the mica, talc, and titanium dioxide finely for makeup products.

Chemical and pigment manufacturing

Dye and pigment dispersion: Using the ball milling machines for powder processing, it achieves uniform particle size for paints, inks, and coatings.

Catalyst preparation: By fine grinding, it can activate catalysts such as zeolites, metal oxides, etc.

Looking for suitable fine powder milling machines, Daswell ball mill machine can process your materials, whose mosh hardness is under 7. We can customize the ball mill plant solutions according to your production requirements. Besides, there are also crushing plants for you to prepare the materials for ball milling.

And except for the ball mill machines, Daswell also offers you ring roller mill machines and Raymond milling equipment. Both of them can process materials into powder. But they accept different mosh hardness. And the grinding effects, feeding sizes are different as well.

If you have interests, just contact Daswell now. We will recommend the most suitable grinding machine and mill plant for your powder production business.