DASWELL Stationary Crushing Plant (150-200tph) Starts Production in the Philippines

150-200tph Stationary Crushing Plant Projects in the Philippines Overview

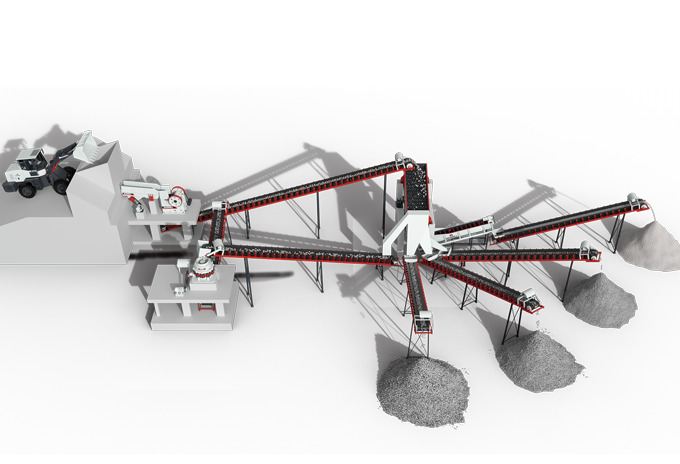

In 2022, DASWELL supplied a stationary crushing plant with a capacity of 150-200 tons per hour to a road construction company in the Philippines. This crushing equipment is used to process materials such as gravel, sand, and crushed stone, which are essential for road construction and maintenance.

The stationary crushing plant includes a comprehensive setup consisting of a feeder, jaw crusher, cone crusher, screen, sand washer, and separator, all designed for optimal operation in harsh working environments. Choosing this stationary crushing equipment with a capacity of 150-200 tons per hour can meet the customer’s production needs and provide reliable high capacity.

Advantages of this stationary crushing equipment

- High Capacity: Capable of processing between 150 and 200 tons of materials per hour, this stone crusher plant ensures a steady and reliable output, meeting the high demands of road construction.

- Advanced Crushing Technology: The jaw crusher and cone crusher in this system are equipped with cutting-edge technology for superior crushing efficiency, reducing the need for manual labor and boosting overall productivity.

- Versatile Performance: The plant is equipped with a screen and sand washer, ensuring that materials are not only crushed but also properly screened and washed for purity and quality.

- Durability and Efficiency: Built with robust materials and designed for continuous operation, the stationary crushing plant delivers high uptime with minimal maintenance.

Why the Customer Chose DASWELL for Their Stationary Crushing Plant Needs

DASWELL is renowned for providing high-quality, cost-effective solutions. DASWELL’s 150-200 ton/hour stationary crushing units can handle large quantities of material with minimal downtime. Customers have also visited local construction companies using our equipment.

Another reason for choosing DASWELL is our fast delivery and excellent after-sales service. With 39 years of experience serving customers, we provide a complete range of spare parts to ensure smooth operation and maintenance.

Detailed Equipment Configuration of the Stationary Crushing Plant

The 150-200tph Stationary Crushing Plant provided to the customer is a highly sophisticated piece of machinery, with each component carefully designed to work in harmony for optimal output. The main technical specifications include:

- Feeder: Equipped with an adjustable vibrating feeder, ensuring a steady flow of material to the crushers.

- Jaw Crusher: A robust primary crushing unit that can handle large, tough materials. The crusher is designed for high throughput, offering reduced wear and tear, which translates to lower maintenance costs.

- Cone Crusher: A secondary crusher that ensures finer material output, ideal for further processing or directly meeting quality standards.

- Screen: A multi-layered vibrating screen that ensures precise separation of various sizes of aggregates, improving the overall quality of the material.

- Sand Washer: The sand washer effectively removes impurities and fines from the materials, enhancing the quality of the sand and aggregates produced.

- Separator: This unit is used to separate the fine dust and other contaminants, ensuring that the final product meets environmental standards.

Delivery and Customer Feedback of Stationary Crushing Equipment

This stationary crushing plant, with a processing capacity of 150-200 tons/hour, was delivered to the customer’s site on schedule in 2022. The transportation process went smoothly; all equipment was carefully packaged and packed into multiple containers to ensure safe transport.

The installation process lasted approximately one week. During this time, after installation, engineers trained the customer’s operators on equipment operation, maintenance, and safety procedures.

After the 150-200 tons/hour stationary crushing plant went into operation, it consistently produced 150-200 tons of aggregate per hour, far exceeding the output of the customer’s old equipment, and the customer was very satisfied. The customer also expressed interest in continuing their partnership with DASWELL in future projects.

Contact DASWELL today and let us be your partner in building a more efficient future.