Concrete Pumps

Concrete Pumps usually use pressure to transport concrete along the pipeline continuously. Our Concrete pumping machines popular products are mainly concrete boom pump truck, trailer pump, concrete mixer pump, etc.

Concrete pump machinery

What are concrete pumps?

A concrete pump is mainly used for transportation. It can transfer the liquid concrete from the mixing site to the pouring location efficiently. The concrete pumping equipment eliminates manual labor and speeds up construction. Meanwhile, it ensures precise placement.

For high-rise buildings, bridges, tunnels, and large-scale infrastructure projects, our concrete pumps are your ideal choice. Daswell company has three types of pumps for your different concrete pumping requirements.

The concrete mixer pumps combine mixing and pumping functions. The concrete mixer hydraulic pump is more suitable for remote sites and small-scale projects.

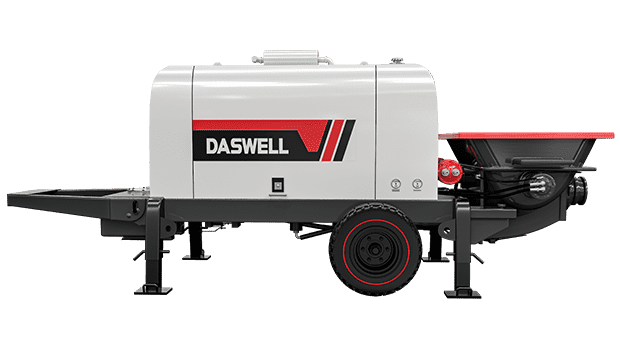

Trailer pumps are suitable for long-distance and vertical projects. You can adopt it for dams, bridges, and skyscrapers.

A concrete boom pump is also called a truck with concrete boom pump. It equipped with a hydraulic arm for placing flexibly. This boom pump truck is applicable for urban construction, high-rises, large slabs, etc.

Daswell concrete pumps machines display video

5 Advantages of using concrete pumps for construction

- Suitable for high-rise construction: Using a concrete pump, can push concrete to high-rise construction easily. Especially, our concrete boom pumps are popular among customers for urban high-rises.

- Improving the efficiency: The traditional pouring method needs about 20 workers with low pouring speed. While choosing our concrete pump machine needs fewer operators. 4 workers can operate the concrete pumping equipment. And the pumping speed is 6 faster than manual pouring.

- Move conveniently: Both our concrete pump with mixer and the trailer pump machines have wheels for moving in construction sites conveniently. And the boom pump truck can over obstacles easily.

- Reducing costs: Utilizing concrete pumps can reduce both the labor costs and the time.

- Improving Safety: It is reported that 62% fewer accidents on pump-equipped sites. Adopting concrete pumping machines for working, can eliminate workers falling from the formwork. At the same time, it can avoid slip hazards from spilled concrete.