Diesel Drum Mixer

Diesel drum mixer has the advantages of reliable transmission, easy to operate and low energy consumption. It is suitable for concrete component factories and general construction sites, roads, bridges and other projects. And the use of diesel engine can realize the smooth work of the machine under harsh working conditions.

What is a diesel drum mixer?

The diesel drum mixer is a versatile and robust machine designed for efficiently mixing cement, sand, water, and other aggregates to produce concrete. Daswell has been manufacturing diesel drum concrete mixers for many years. We have different types of diesel drum mixers for you to choose.

Main features of Daswell diesel drum mixer machine

- Diesel-Powered Operation: Different from the electric twin-shaft mixers and planetary mixing machines, it is mainly powered by diesel engine. Thus,you can use it in remote or off-grid locations with unstable power supply. Meanwhile, it ensures consistent performance in harsh conditions.

- Gravity-Based Mixing Mechanism: It utilizes the rotation of the drum and gravity for blending and mixing materials uniformly. You do not need to equip with a complex mechanical agitators, reducing your maintenance costs.

- Portable and Easy to Operate: Daswell diesel engine drum mixing machine can be transported to different job sites. Thus, it is suitable for mobile construction projects. And it is easy for you to operate it for quick and efficient mixing.

- Durable Construction: Our drum mixers are built with high-quality materials to withstand heavy-duty use in construction environments. Thy are resistant to wear and tear, ensuring a long service life.

Applications of Daswell drum mixer machines for your projects

If you need a concrete mixing machine, which can be used for some locations with unstable electricity, or some harsh environments where electric mixers may fail, the diesel drum mixer machine will be a ideal choice.

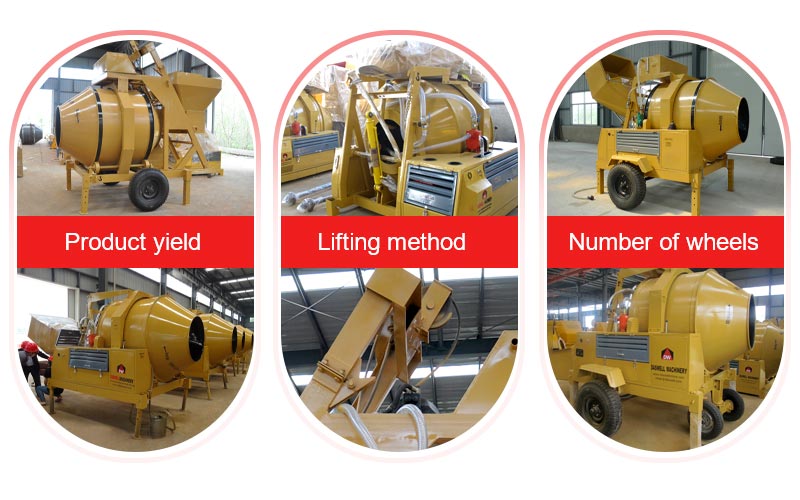

What are the Types of Diesel drum mixer Daswell Provided?

According to different requirements, Daswell has two types of diesel drum mixers for you to choose. For example, we have 350L and 500L mixers according to your capacity requirements. And we also have hydraulic and wire rope lifting drum mixers. Besides, it is also available for you to choose the two wheel design and four wheel design drum mixers. Here you can know them better for your selections:

Classified by Output(Discharging Volume)

- The 350L diesel drum mixing equipment is ideal for small to medium projects. For example, you can use it for rural construction or some small buildings. Its concrete output is low. It is suitable for your shorter construction periods or limited demand.

- The 500L drum mixer machines are best for medium and large projects. For example, it is applicable for roads and bridges. This machine has higher productivity, reducing the mixing cycles for faster completion.

Classified by Lifting Method

- The hydraulic lifting methods can operate smoothly, stably. And it is durable for long-term use. This hydraulic type drum mixer is best for heavy-duty or frequent-use scenarios.

- Compared the hydraulic lifting drum mixers, wire rope lifting is simpler and it is easier and cheaper for you to maintain it. If you do not have much budget, this types of mixers will be suitable for you.

For your reference, if you choose the hydraulic lifting method, it requires hydraulic maintenance. And the wire rope is a wear part. It should be replaced regularly.

Classified by Number of Wheels

- Generally, the standard configurations is 2-wheel. It is economic and suitable for straightforward towing.

- The 4-wheel drum mixer enhances the maneuverability. It is easier for you to turning it in some tight job site. It is worth to mention that the four wheel type mixers has higher price because of the added wheels.

Daswell two wheel drum mixing facility is sufficient for your simple transportation needs. And the four wheel type improves the mobility on rough terrain.

Why Choose Our Diesel Drum Mixer for Your Concrete Projects?

Low Investment and Operating Costs

- Affordable upfront cost – The diesel drum mixer is compact, and its structure is simple with minimal wear parts.

- Durable wear-resistant steel – We choose high quality steel for manufacturing the machine. It reduces long-term maintenance expenses.

- Fuel-efficient diesel engine – It do not need to use electricity, saving operational costs.

Smart and Humanized Design

- Protected diesel engine – There is a cover to prevent damage from dust and debris.

- Integrated water pump and weighing system – Our drum mixers can add water automatically. And it can precisely mix without manual labor.

Portability and Flexibility

- Built-in wheels (2 or 4-wheel options) – It is easy for you to tow between job sites.

- Ideal for remote areas – You can use it in power-scarce regions or rugged terrains.

Wide-Ranging Applications

For some villages or mountainous areas which is unstable or no-grid, Daswell diesel drum concrete mixer is applicable. You can also use it for roads, bridges, prefab plants, and other construction projects.

Effortless Operation

- Simple gear-driven rotation – It is easy for you to operating. The forward is for mixing and reverse for discharging.

- Includes training materials – When we delivering the machines, there will be manuals and videos for quick operator training. Besides, we can also arrange engineer for training your workers on-site.

For contractors prioritizing cost-efficiency, durability, and flexibility, our diesel mixer is the best all-round solution. Whether you’re in a city or off-grid, it delivers reliable performance with minimal downtime.

Interested in a customized quote? Let us know your preferred specifications about output, wheels, lifting method!

How to properly use a diesel drum mixer?

For making your concrete mixing effects better, there are some tips for you when operating the diesel drum mixer machine. From pre-mixing preparation to post-operation maintenance, there are some suggestions for you.

Pre-mixing Preparation

- In order to ensure the quality of the concrete mixture, before mixing, you should configurate the cement, sand and water according to a certain proportion. At the same time, the hopper is required to discharge cleanly, otherwise it will affect the mixing ratio of the next mixture.

- Place the diesel drum mixer on a flat and solid site, and there should be good drainage ditches around it. When the machine is working, put down the outriggers to jack up the frame and keep the tires off the ground.

Safety Checking for Operation

- Before the operation, the no-load test should be carried out. The staff should observe whether the rotation direction of the mixing drum or blade is consistent with the direction shown by the arrow. At the same time, check whether there is impact and jitter. If there is abnormal noise, it should be stopped for inspection.

- When the hopper is lifted, it is strictly forbidden for anyone to stay or pass under the hopper. If it must be repaired under the hopper, the hopper should be lifted and then locked with an iron chain.

Post-operation Maintenance

- When the mixing process finish, you had better pour some gravel or sand into the mixing drum. After 10 minutes of stirring, they can be released. Otherwise, once the residual concrete has set, it will be difficult to remove. Moreover, there should be no accumulated water in the barrel to avoid rusting of the barrel and the blades.

FAQ about Daswell Diesel Drum Mixer

Technical Data:

| Model | DMD350DW | DMD350DH | DMD500DH | DMD500DS |

| Charging Volume (L) | 560 | 560 | 750 | 750 |

| Discharging Volume (L) | 350 | 350 | 500 | 500 |

| Capacity (m3/h) | 10-14 | 10-14 | 18-22 | 18-22 |

| Max. Aggregate Size (mm) | Cobble: 40 Gravel: 60 | Cobble: 40 Gravel: 60 | Cobble: 60 Gravel: 80 | Cobble: 60 Gravel: 80 |

| Hopper Lifting Mode | Wire rope lifting | Hydraulic tipping hopper | Hydraulic tipping hopper | Hydraulic tipping hopper |

| Diesel Engine Power (kw) | 13.2 | 13.2 | 16.2 | 16.2 |

| Dimensions (L×W×H) (mm) | 3100×2320×3070 | 3250×2240×3200 | 3750×2240×3800 | 3900×2300×3750 |

| Weight (t) | 1.85 | 1.78 | 2.28 | 2.35 |