Self Loading Concrete Mixer for sale Indonesia

- Time: Jan 5

- Destination: Indonesia

- Equipment: DASWELL SLDM3500 self loading concrete mixer

- Quantity: 2 units

- Customer need: Fast, independent concrete mixing on site; fewer machines and fewer “handoffs”

- Solution: 2× SLDM3500 self loading concrete mixer to load + mix + move concrete with one workflow

Self Loading Mixer: The “2-Machine” Reason

On many Indonesian sites, work is fast and the crew needs a steady rhythm. If only one unit is available, any pause—loading, repositioning, cleaning, or a short check—can break that rhythm. With two SLDM3500 self loading concrete mixers, the customer can keep work moving in a simple way:

- one unit stays in the loading/mixing loop

- the other unit is already moving to the pour point or coming back

Self Loading Concrete Mixer Truck: What the Customer Was Worried About

- “Can our crew run it without a specialist?”

They wanted a machine that operators can learn fast. Not a setup that depends on one experienced person. - “Will it really reduce equipment on site?”

Many sites still rely on a loader + mixer truck (or small mixer) + manual moving. That creates extra coordination and a crowded work area. The customer wanted a cleaner workflow.

Self Loading Mixer: How the Workflow Looks

A self loading concrete mixer is popular because it compresses steps. The self loading concrete mixer is used like this on many sites:

- Self-load aggregates into the bucket

- Charge into the drum and mix

- Drive to the pour area

- Discharge and repeat

It removes common bottlenecks:

- waiting for a loader

- waiting for a separate mixer

- moving concrete with too many small transfers

Self Loading Concrete Mixer: Why This Model Fit

Customers usually choose self loading mixer when they want a balance of productivity and mobility.

- One-machine workflow: loading + mixing + moving in one unit

- Less site coordination: fewer machines to schedule, fewer handoffs

- Flexible operation: easier to adapt when the work area shifts

- Practical for mixed sites: suitable for jobs where the pour locations change during the day

This is why self loading concrete mixers are often chosen for fast-moving site work: the machine supports the crew’s rhythm instead of forcing the crew to wait on equipment.

What Matters When You Buy 2 Units Concrete Mixer

Customers usually care about:

- Clear packing and loading plan: easier to check and receive equipment on arrival

- Document completeness: avoids delays at the next step

- Commissioning readiness: so the crew can move from delivery to operation without confusion

DASWELL’s job is to make that process predictable—especially when the customer is trying to start work soon after arrival.

Customer Feedback: What They Liked About Self Loading Mixer

The customer told us, “It’s easier to run than we expected. The crew picked it up quickly.” They also said the biggest change was the rhythm on site: “With two self loading concrete mixer trucks, we don’t have to stop and wait so much. One can be loading and mixing while the other is moving to the pour area. That keeps the work going and makes the day easier to plan.”

In short, self loading concrete mixer helped them keep a steady jobsite rhythm with fewer slowdowns.

More Options Beyond Self Loading Concrete Mixer

If your Indonesia project grows beyond self-loading mixers, DASWELL Group can also support full concrete supply setups, including:

- Mobile concrete batching plants for larger on-site batching needs

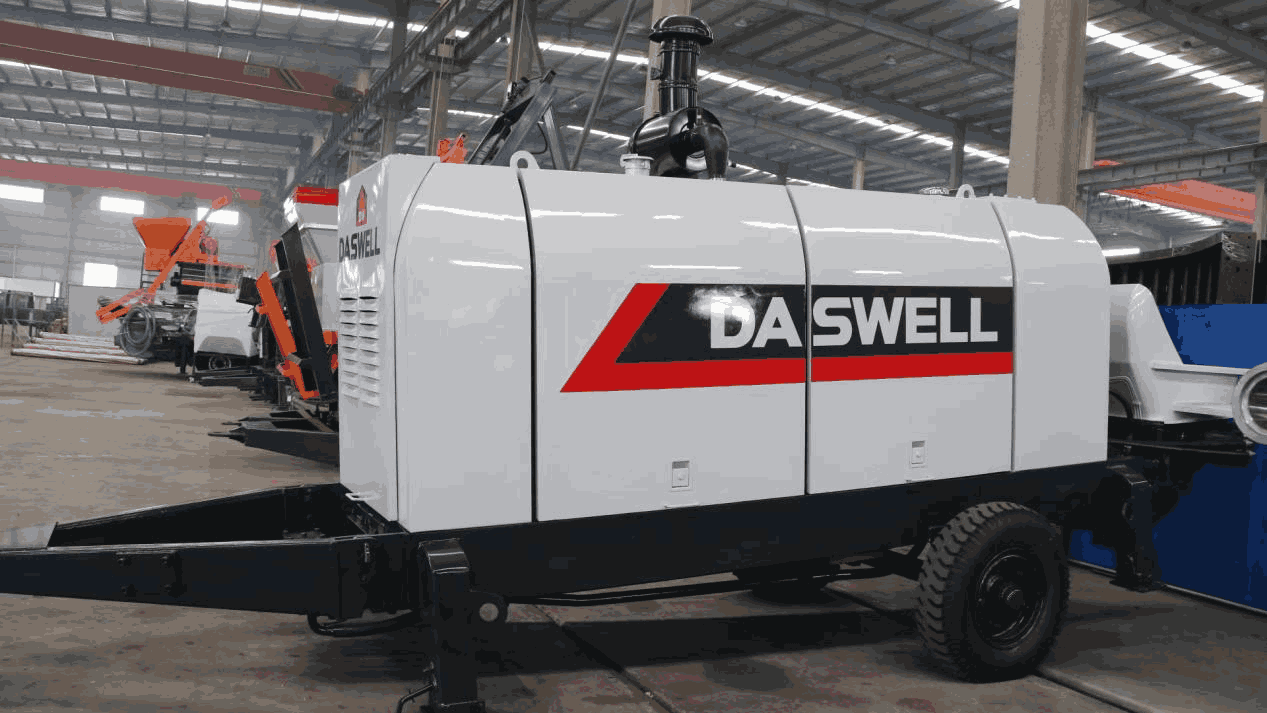

- Concrete mixer pumps when you need mixing + pumping on one unit

- Stationary batching plants for long-term sites with fixed location needs

If you’re considering a self loading concrete mixer, tell us what kind of job you’re doing and how your site is set up. We’ll suggest the setup that fits how your crew works.