Concrete Batching Plant CBP60 Project in Manila, Philippines is under construction smoothly

Project introduction

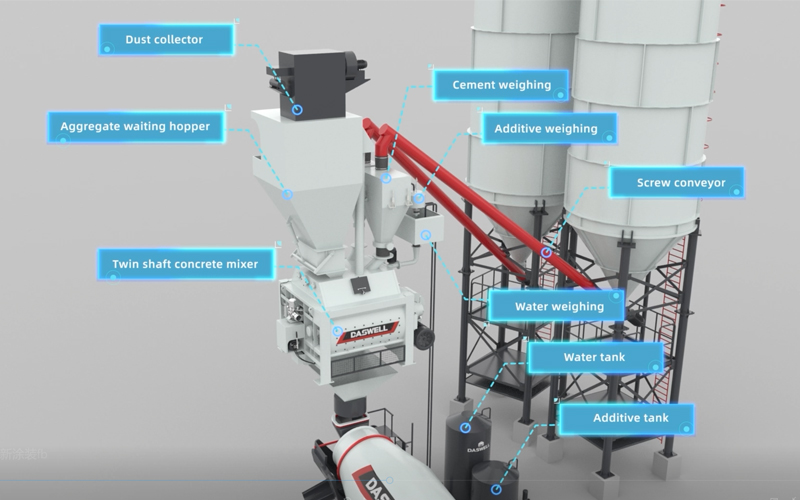

For an infrastructure construction project in the Philippines, a client selected a Daswell CBP60 concrete batching plant as its core production equipment. Located near Manila, the project primarily focuses on road and urban infrastructure construction, requiring high concrete production volumes and high-quality continuous feed. We provided the client with a complete CBP60 batching plant production line, including a main mixer, aggregate batcher, cement silo, screw conveyor, and fully automatic control system. Furthermore, the Daswell technical team provided comprehensive support, from equipment selection and transportation, installation and commissioning, to operator training, ensuring the plant’s rapid commissioning and ensuring the smooth and efficient progress of the project.

Customer requirements and difficulties

The client for this project is a large local construction contracting company in the Philippines, specializing in road, bridge, and municipal engineering. This project, a major urban trunk road expansion project, required a tight construction schedule and placed extremely high demands on concrete quality and supply stability. The large scale of the project required hundreds of cubic meters of concrete daily, and the widespread construction sites created significant challenges in coordination and transportation.

The project’s challenges were:

1. The tight construction schedule necessitated ensuring continuous concrete production and rapid supply;

2. The local high temperature and heavy rainfall placed higher demands on the stability of concrete production and the reliability of equipment operation;

3. The project involved the construction of multiple structures, imposing strict standards for concrete strength grade and mixing uniformity.

Therefore, the client urgently required an efficient, stable, and highly automated concrete mixing plant to meet the continuous material supply requirements of this large-scale construction project.

How customers choose Daswell

The client initially learned about Daswell through Google online search and, through discussions with our experienced sales manager, received recommendations from several customers who had used Daswell equipment. Subsequently, the client visited our official website and reviewed several overseas case studies, including successful projects in Southeast Asia, the Middle East, South America and Africa. This gradually led to a trust in Daswell’s equipment capabilities and service offerings.

During discussions with our sales and technical teams, the client inquired in detail about the CBP series concrete mixing plants’ production capacity, configuration options, operational stability, and after-sales support. After multiple rounds of technical discussions and solution optimization, the client ultimately chose the Daswell CBP60 concrete mixing plant for the following key reasons:

- The project was under tight schedule, requiring continuous concrete production and rapid supply.

- The local high temperature and heavy rainfall placed higher demands on the stability of concrete production and the reliability of equipment operation.

- The project involved multiple structural construction, requiring stringent standards for concrete strength grade and mixing uniformity.

Therefore, the client urgently required an efficient, stable, and highly automated concrete mixing plant to meet the continuous material supply requirements of this large-scale construction project.

Equipment configuration list

The CBP60 concrete batching plant delivered this time has the following configuration:

Equipment Model: CBP60 Concrete Batching Plant

Production Rate: 60 m³/h

Mixer Model: TCM1000 Twin-Shaft Mixer

Mixer Motor Power: 2 x 18.5 kW

Mix Cycle: 60 seconds

Aggregate Weighing Accuracy: ±2%

Powder Weighing Accuracy: ±1%

Conveyor Method: Belt Conveyor

Control System: Fully Automatic Computer Control + Manual Control

Accessories: A batch of wearing parts, lubrication system, operating instructions, electrical control cabinet, etc.

The whole process of installation and debugging

After the CBP60 completed production testing at the Chinese factory, the entire machine was shipped to the Philippine port via shipping container and then transported to the construction site by truck. The Daswell technical team confirmed the foundation construction plan with the customer before the equipment arrived to ensure that the installation conditions were met on site.

The installation process is divided into several stages:

1.Equipment Unloading and Positioning – Engineers directed the crane to safely unload the equipment and placed the mixer, batching machine, conveyor belt, and electronic control system in their proper locations.

2.Structural Assembly and Fixing – The main mixer was installed on a steel platform, the conveyor belt and silo were gradually connected, and all components were reinforced.

3.Electrical and Piping Connections – Electrical system wiring, sensor calibration, and pneumatic and hydraulic system installation were performed.

4.System Commissioning: A no-load test run was conducted to check the accuracy of the motor, electronic control system, and weighing system.

5.Trial Production: A trial mix of sand, gravel, and cement was conducted to test the uniformity, strength, and discharge accuracy of the concrete.

6.Training and Delivery: Technicians provided operational training, troubleshooting, and maintenance instruction to the customer’s operators, ensuring they could independently operate and maintain the equipment.

The entire installation and commissioning process was successfully completed in just two weeks, and the equipment was quickly put into full production.

Customer feedback and actual results

After its official launch, customers were very satisfied with the Daswell CBP60’s performance. Feedback primarily focused on the following aspects:

High production efficiency: A stable output of 60m³ per hour met the concrete demand during peak construction periods.

Stable quality: The fully automatic weighing system ensures accurate batching, uniform concrete discharge, and near-100% strength compliance.

Cost reduction: Automated control reduces labor requirements, reducing labor costs by approximately 30%.

Shortened construction schedule: Stable equipment operation shortened the overall construction period by approximately 20%, enabling the project to be completed ahead of schedule.

High return on investment: Compared with traditional mixing methods, the unit concrete production cost was reduced by approximately 15%, resulting in greater profit margins.

Customer Comment:

“Daswell’s concrete mixing plant has significantly improved our construction efficiency and management level. This not only increases the project’s economic benefits but also provides reliable support for subsequent projects. We look forward to continuing our partnership with Daswell in the future.”

Outlook for future cooperation

With the successful commissioning of this project, the customer has expressed their intention to continue purchasing Daswell concrete mixing plants and pumping equipment for subsequent bridge construction projects. We will continue to provide comprehensive technical and service support to facilitate the customer’s development in the Philippines and Southeast Asian markets.